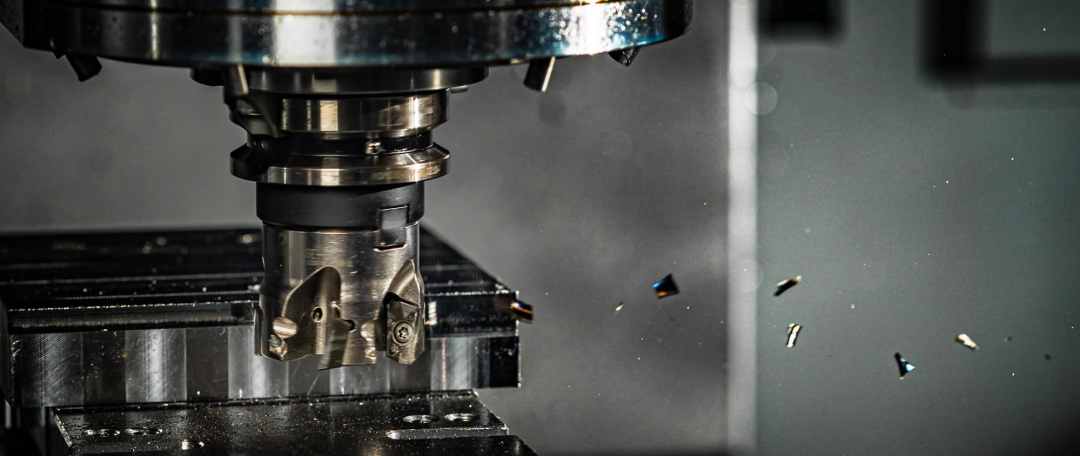

Welcome to our comprehensive guide on how to change chuck on milling machine. Whether you are a seasoned professional or a new operator, understanding the intricacies of a milling machine is crucial for efficiency and productivity.

Understanding the Importance of the Chuck

The chuck is a vital part of the milling machine. It holds the workpiece in place and ensures precision during the machining process. Knowing how to change the chuck properly can significantly improve your machining operations.

Types of Chucks Available

Three-Jaw Chucks

Three-jaw chucks are widely used for their ability to center workpieces automatically. They are ideal for round and hexagonal items.

Four-Jaw Chucks

Four-jaw chucks offer higher flexibility in gripping various shapes. They require manual centering, which can be a bit time-consuming.

Magnetic Chucks

Magnetic chucks are used for holding ferromagnetic materials in place. They are quick to set up and offer tremendous holding power.

Preparation Before Changing the Chuck

Safety Precautions

Always prioritize safety. Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses. Ensure the machine is turned off and properly locked out.

Tools Required

Gather the necessary tools before starting the procedure. Common tools include a chuck key, Allen wrench, and a rubber mallet.

Step-by-Step Guide on How to Change the Chuck

Step 1: Removing the Current Chuck

Begin by loosening the screws that hold the chuck in place using the appropriate wrench. Carefully remove the chuck from the spindle.

Step 2: Cleaning the Spindle

Thoroughly clean the spindle to remove any debris or old grease. This ensures a snug fit for the new chuck.

Step 3: Installing the New Chuck

Position the new chuck onto the spindle. Tighten the screws evenly to secure the chuck in place. Ensure it is firmly attached to prevent any wobbling during operation.

Best Practices for Maintaining Your Chuck

Regular Cleaning

Clean the chuck regularly to prevent the accumulation of debris and ensure its longevity.

Lubrication

Apply appropriate lubricant to the moving parts of the chuck to reduce friction and wear.

Inspection

Periodically inspect the chuck for any signs of wear and tear. Replace worn-out parts promptly to avoid any downtime.

Common Issues and Troubleshooting

Chuck Wobbling

If the chuck wobbles during operation, check for loose screws or debris on the spindle. Tighten the screws and clean the spindle thoroughly.

Difficulty in Changing the Chuck

If you encounter difficulties while changing the chuck, refer to the machines manual for specific instructions. Seek assistance from a professional if needed.

Advanced Tips for Expert Operators

Optimizing Chuck Performance

Ensure the chuck is centered accurately to achieve better precision in machining. Use a dial indicator to check for any runout and make necessary adjustments.

Utilizing Specialized Chucks

Consider investing in specialized chucks, such as collet chucks or hydraulic chucks, for specific machining tasks. These chucks offer enhanced accuracy and efficiency.

Summary

Changing the chuck on a milling machine is a crucial skill that can greatly impact your machining operations. By following the steps outlined in this guide, you can ensure a smooth and efficient chuck change process.

FAQs

- What safety precautions should I take when changing the chuck on a milling machine?

Always wear appropriate PPE, turn off the machine, and lock it out before starting the procedure.

- How often should I clean my chuck?

Regular cleaning is recommended to prevent debris accumulation and ensure smooth operation.

- What should I do if the chuck wobbles?

Check for loose screws or debris on the spindle. Tighten the screws and clean the spindle thoroughly.

For more information on milling machines and their operation, visit this article on milling machines.

Check out these other articles: Paint inspection, Genetic analysis, Wafer polishing.