Connecting a tachometer is a pivotal skill, especially in the realm of industrial quality assurance and monitoring. For those who are new to this, a tachometer is a device that measures the speed of rotation in machines. This article will walk you through the process with deliberate steps and useful tips.

Introduction to Tachometer Technology

A tachometer serves a crucial function in various industries. Understanding the technology behind it can ease the process of connecting and utilizing it effectively.

What Is a Tachometer?

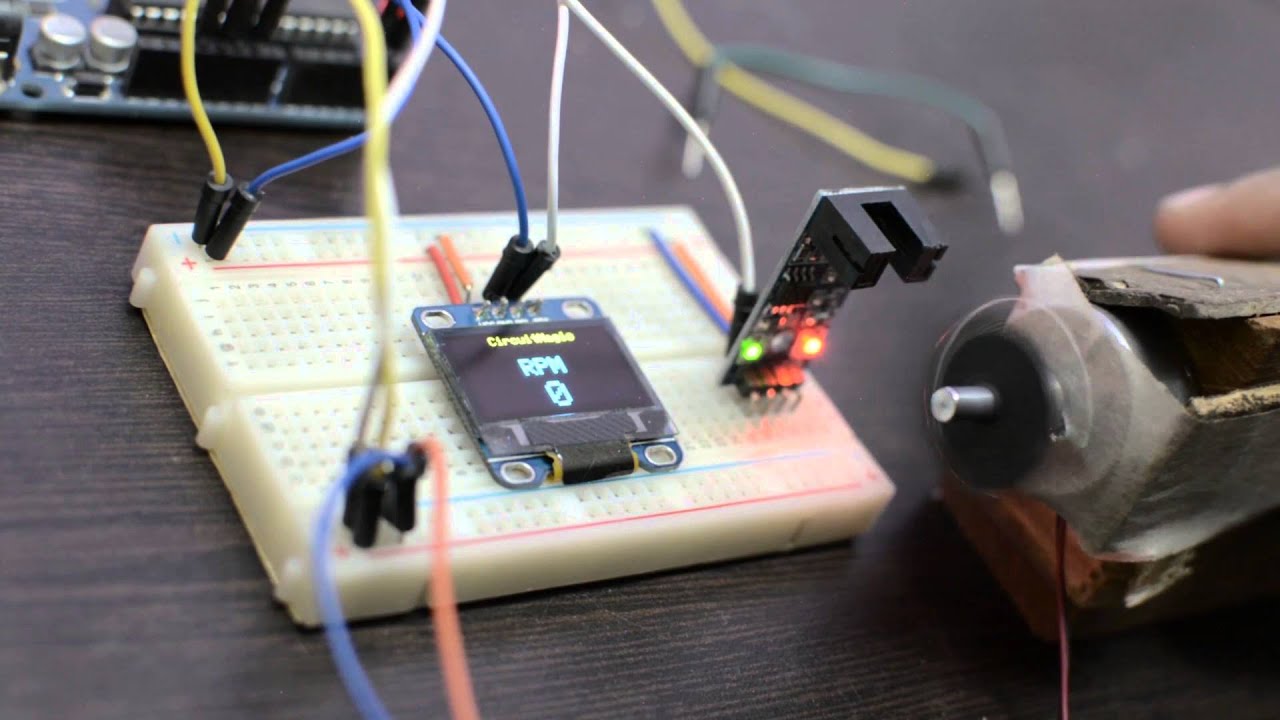

The tachometer is a device that measures the rotation speed of an object, usually a shaft or disk, and displays it in RPM (Revolutions Per Minute). Click here to learn more about how tachometers work from a trusted source.

Types of Tachometers

Tachometers come in various types, such as digital, analog, contact, and non-contact varieties. Choosing the right type depends on your specific needs and the environment in which the tachometer will be used.

Tools and Materials Needed

Before you start, gather all necessary tools and materials. This reduces the chances of any interruptions during the connection process.

Basic Tools

- Screwdrivers

- Wire Strippers

- Electrical Tape

- Multimeter

Materials Required

- Tachometer

- Mounting Bracket

- Wiring Harness

- Connectors and Terminals

Steps to Connect a Tachometer

Now, lets get into the actual steps to connect a tachometer.

Step 1: Identify the Tachometers Wiring Diagram

Understanding the wiring diagram is crucial. Make sure to consult the manual that comes with your tachometer.

Step 2: Prepare the Wires

Use wire strippers to strip about half an inch of insulation from the ends of the wires that you will be connecting.

Step 3: Mount the Tachometer

Secure the tachometer in its mounting bracket and position it where its easily visible.

Step 4: Connect the Ground Wire

Find a secure and non-corrosive ground point, and connect the tachometers ground wire to this point.

Step 5: Connect the Power Supply

Connect the tachometers power wire to an ignition-switched power source.

Step 6: Connect the Signal Wire

The signal wire typically goes to the negative side of the ignition coil. Ensure that this connection is secure to avoid any malfunction.

Step 7: Double-Check Connections

Before turning on the vehicle or machine, double-check all your connections to ensure that everything is secure and accurately placed.

Step 8: Test the Tachometer

Start the vehicle or machine, and check if the tachometer is functioning correctly. If not, turn it off and check the connections again.

Troubleshooting Common Problems

If you encounter problems, dont worry. Here are some common issues and how to fix them.

No Power to Tachometer

Check the power supply and grounding points. Ensure that they are securely connected.

Fluctuating Readings

Fluctuating readings can be due to a poor signal connection. Re-check the signal wire’s connection to the ignition coil.

Inaccurate Readings

Verify that the tachometer is configured correctly for your engine type.

When to Seek Professional Help

Although connecting a tachometer can often be done with basic knowledge and tools, there are situations where seeking professional help may be necessary.

Complex Machinery

If youre working with complex machinery, its best to consult a professional to avoid any potential risks.

Lack of Confidence

If youre not confident in your ability to make the connections properly, seeking expert help can save time and prevent damage.

Additional Resources

For more detailed guidance on tachometer connections and industrial quality assurance, feel free to visit our additional resources: Wafer Polishing, Paint Inspection, Genetic Analysis.

Conclusion

Connecting a tachometer might seem daunting at first, but with the right tools and guidelines, it becomes a manageable project. This guide provides all the necessary steps and tips to make the process smooth and efficient.

FAQs

Can I use a tachometer on any engine?

Most tachometers can be used on various engine types, but its essential to refer to the tachometers manual to confirm compatibility.

Do I need specialized tools to connect a tachometer?

No, basic tools such as screwdrivers, wire strippers, and electrical tape will suffice for most tachometer connections.

What should I do if my tachometer is not working?

If the tachometer is not working, re-check all connections, consult the manual, and if needed, seek professional help.