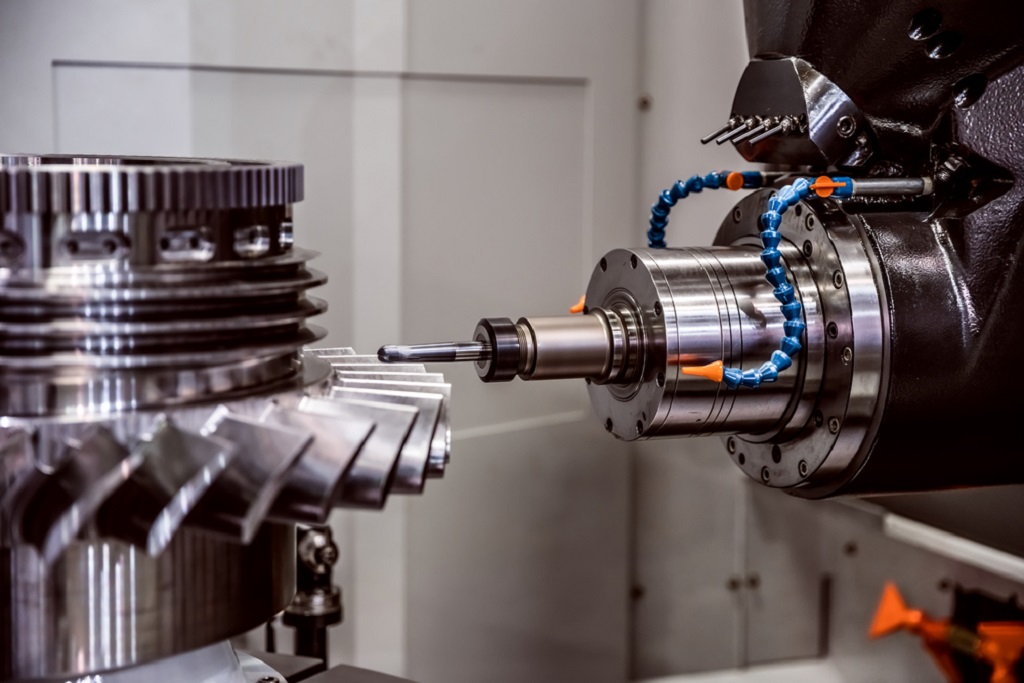

Cutting helical gears in a milling machine is a crucial process in various engineering and manufacturing applications. It requires precision, the right tools, and a step-by-step approach to achieve the desired accuracy and efficiency. This article will guide you through the detailed steps of cutting helical gears, ensuring that you can execute this task with confidence and expertise.

Understanding Helical Gears

Helical gears are characterized by their angled teeth, which are designed to engage more gradually than those on straight-cut gears. This gradual engagement results in a smoother and quieter operation, making helical gears ideal for high-speed applications.

Advantages of Helical Gears

- Smoother operation

- Higher load capacity

- Reduced noise and vibration

Preparing the Milling Machine

Before you begin cutting helical gears, it is essential to prepare your milling machine properly. Ensure that the machine is clean, well-lubricated, and free of any obstructions. Additionally, you must secure the appropriate gear-cutting tools and ensure that the machine’s settings are adjusted to meet the requirements of your specific project.

Choosing the Right Tools

Selecting the right cutting tools is vital to the success of your project. This includes choosing the right type of milling cutter, as well as any necessary attachments or accessories that will assist in the cutting process.

Setting Up the Workpiece

Securely mounting the workpiece is critical to ensure accuracy during the cutting process. Use precision clamps or fixtures to hold the workpiece in place, and double-check the alignment before proceeding.

Calculating the Helix Angle

The helix angle is a vital parameter in cutting helical gears. You can calculate the helix angle using the formula:

Helix Angle = arctan (Lead / ( * Diameter))

Lead and Diameter

In this formula, ‘Lead’ refers to the distance the gear teeth travel along the gear’s axis in one complete revolution, while ‘Diameter’ is the reference diameter of the gear. Ensure you have accurate measurements for these values to calculate the helix angle correctly.

Setting the Milling Machine

Once you have calculated the helix angle, set the milling machine to the required angle. This may involve adjusting the machine table or using specific attachments to achieve the precise angle.

Milling Cutter Alignment

Align the milling cutter with the calculated helical path. This may require fine-tuning the machine settings and making several trial cuts to ensure accuracy.

Commencing the Cutting Process

With everything set up correctly, you can begin the cutting process. Ensure you maintain a steady feed rate and monitor the progress closely to avoid any deviations.

Quality Control

During the cutting process, regularly inspect the gear to ensure it meets the required specifications. Use precision measuring tools to check the dimensions and make any necessary adjustments.

Post-Cutting Procedures

After completing the cutting process, remove the workpiece carefully and conduct a thorough inspection. Clean the gear to remove any debris and perform any additional finishing operations required.

Deburring and Finishing

After cutting, helical gears often require deburring to remove any sharp edges or burrs. Use appropriate tools and techniques to achieve a smooth finish.

Conclusion

Cutting helical gears in a milling machine involves several detailed steps, each requiring precision and attention to detail. By following the approved methods outlined in this article, you can achieve high-quality results and produce gears that meet industry standards.

FAQ

What are the key benefits of helical gears?

Helical gears offer smoother operation, higher load capacity, and reduced noise and vibration, making them ideal for high-speed applications.

How do I calculate the helix angle?

The helix angle is calculated using the formula: Helix Angle = arctan (Lead / ( * Diameter)). Accurate measurements of lead and diameter are essential for this calculation.

What tools are required for cutting helical gears?

You will need a milling machine, the appropriate milling cutter, precision clamps, and measuring tools to cut helical gears accurately.

For more detailed information, you can visit this external resource.

For additional insights into high-speed manufacturing inspection, you might find this high-speed inspection resource useful.