Industry QA Professionals often rely on tachometers to measure the RPM of machines and engines. However, there are situations where a tachometer is not available, and you must determine RPM through alternative methods. This article serves as a detailed guide on how to figure out RPM without a tachometer, ensuring accuracy and reliability in your measurements.

Why Measuring RPM Without a Tachometer is Important

Understanding RPM (Revolutions Per Minute) is crucial for monitoring engine performance, conducting maintenance, and ensuring safety. Not having access to a tachometer shouldn’t halt your work, especially in industries where precision is paramount.

Methods for Measuring RPM Without a Tachometer

- Using a Stopwatch and Marker: Mark a visible point on a rotating part. Count the rotations in a given time frame using a stopwatch.

- Stroboscopic Method: Use a strobe light synchronized to the rotating part’s speed. Adjust until the part appears stationary.

- Audio Analysis: Record the engine sound and analyze its frequency using audio software to calculate RPM.

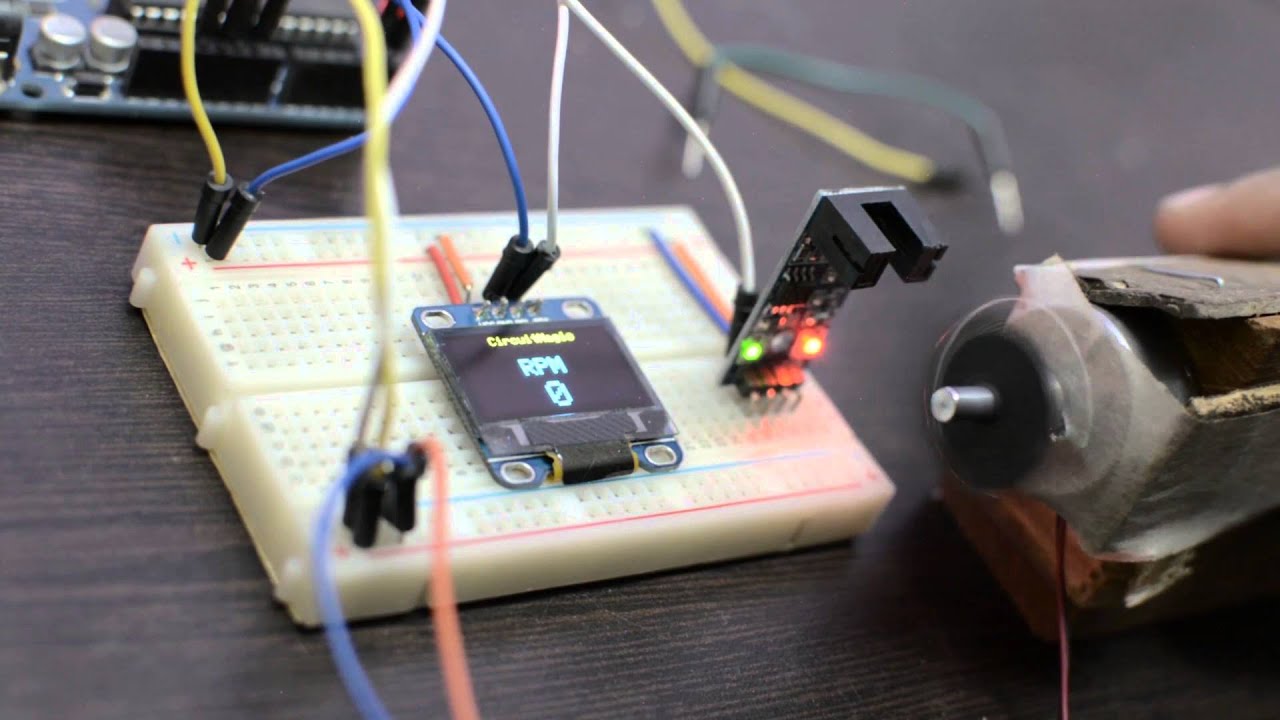

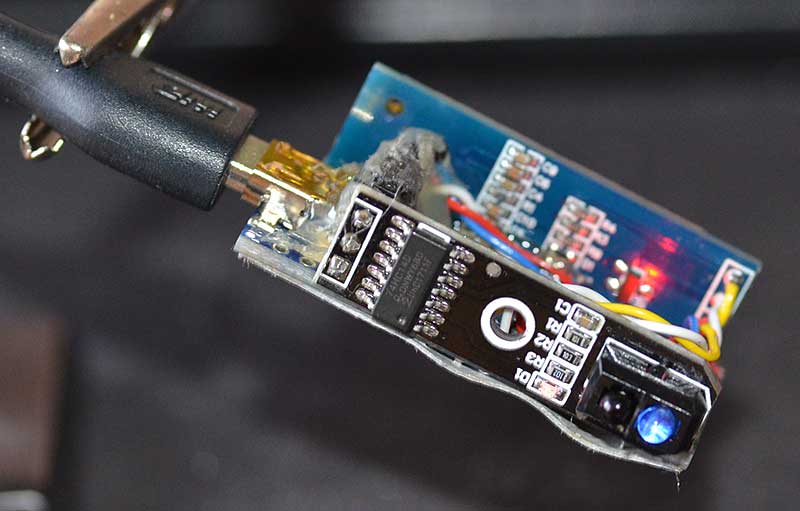

- Multimeter with Frequency Measurement: Some multimeters have frequency measurement capabilities. Attach probes to the engine’s electrical system to get frequency readings.

Step-by-Step Instructions for Each Method

Using a Stopwatch and Marker

This method is straightforward and requires minimal tools. Follow these steps:

- Clean and prepare the surface of the rotating part.

- Make a clear and visible mark on the part.

- Start the engine and simultaneously start the stopwatch.

- Count the number of complete rotations in a pre-determined time interval (e.g., 10 seconds).

- Calculate RPM using the formula: RPM = (Rotations counted / Time (seconds)) * 60

Stroboscopic Method

The stroboscopic method requires a strobe light. Here’s how to use this technique:

- Prepare the stroboscope by adjusting its flash rate.

- Point the strobe light at the rotating part.

- Adjust the flash rate until the part appears to stop moving.

- The flash rate at which the part appears stationary corresponds to the RPM.

Advantages and Disadvantages of Each Method

While all methods can be effective, each comes with its own set of pros and cons. Some are more precise, while others are more convenient. You can read more about the primary purpose of a tachometer on tachometer purpose.

Using a Stopwatch and Marker

Advantages:

- Simple and requires minimal tools.

- Accessible and can be done anywhere.

Disadvantages:

- Potential for human error.

- Less precise for high RPM measurements.

Stroboscopic Method

Advantages:

- High precision and accuracy.

- Non-contact method, reducing safety concerns.

Disadvantages:

- Requires specialized equipment.

- Can be challenging to use in bright environments.

Audio Analysis Method

You can use audio analysis software like Audacity for this method:

- Record the engine sound using a microphone or smartphone.

- Import the recording into the audio software.

- Analyze the frequency spectrum to identify the dominant frequency.

- Convert the frequency to RPM using the formula: RPM = Frequency (Hz) * 60.

Audio Analysis

- Advantages:

- Non-contact method

- Useful for noisy environments where visual methods are impractical

- Disadvantages:

- Requires specialized software

- Accuracy depends on quality of recording

Setting Up Alternative Methods

For industry QA professionals, setting up alternative methods to measure RPM without a tachometer is crucial. Read more.

Using a Multimeter with Frequency Measurement

If you have a modern multimeter, it might have a frequency measurement feature:

- Turn off the engine and connect the multimeter probes to the ignition system.

- Set the multimeter to measure frequency (Hz).

- Start the engine and note the frequency reading.

- Convert the frequency to RPM using the formula: RPM = Frequency (Hz) * 60.

Safety Considerations

When measuring RPM without a tachometer, always prioritize safety:

- Ensure the engine is stable and secure.

- Use proper personal protective equipment.

- Be cautious of moving parts

- Avoid loose clothing or accessories that can get caught

Always double-check your calculations and setup.

Common Challenges and How to Overcome Them

One of the main challenges in measuring RPM without a tachometer is accuracy. Human error can affect stopwatch measurements, while environmental factors can influence stroboscopic readings. Investing in proper tools and taking multiple readings can help mitigate these issues.

Real-World Applications

Measuring RPM without a tachometer is not just a theoretical exercise. It has practical applications in various industries, such as automotive, industrial machinery, and aerospace. Understanding how tachometers work can further enrich your knowledge and improve your alternative measurement techniques.

FAQ Section

Can I accurately measure RPM without a tachometer?

Yes, by using methods like a stopwatch and marker, stroboscopic light, and audio analysis, you can achieve reasonably accurate RPM measurements.

Is it safe to measure RPM without a tachometer?

Yes, it can be safe if you follow proper safety protocols, such as securing the engine, using protective gear, and being cautious around moving parts.

What is the most accurate method for measuring RPM without a tachometer?

The stroboscopic method is often considered the most accurate, but it requires specialized equipment.