Installing a Digital Readout (DRO) on a milling machine might seem like a daunting task, but with proper guidance, it can be accomplished smoothly. Our article aims to assist industry QA professionals and enthusiasts alike. So, if you’ve ever wondered how to install a DRO on a milling machine efficiently, this comprehensive guide is tailor-made for you.

Introduction to DRO

Digital Readouts or DRO systems are essential for enhancing the precision of milling machines. They offer a clear digital display of the machine’s readings, improving accuracy and making the milling process more efficient.

What is a DRO?

A Digital Readout or DRO is an electronic device attached to the various machine tools used in industry applications. By providing digital feedback to the operator, it allows for easier and more accurate readings.

Why Install a DRO?

The installation of a DRO system brings several advantages. It improves precision, allows for easy measurement readings, and speeds up the milling process by reducing manual error.

Benefits of a DRO

- Increased precision

- Simplified operation

- Time-saving

- Reduced manual error

Necessary Tools and Materials

Before beginning the installation, gather all necessary tools and materials. These may include a DRO kit, appropriate wrenches, screwdrivers, drilling tools, and a mounting system.

Step-by-Step Installation Guide

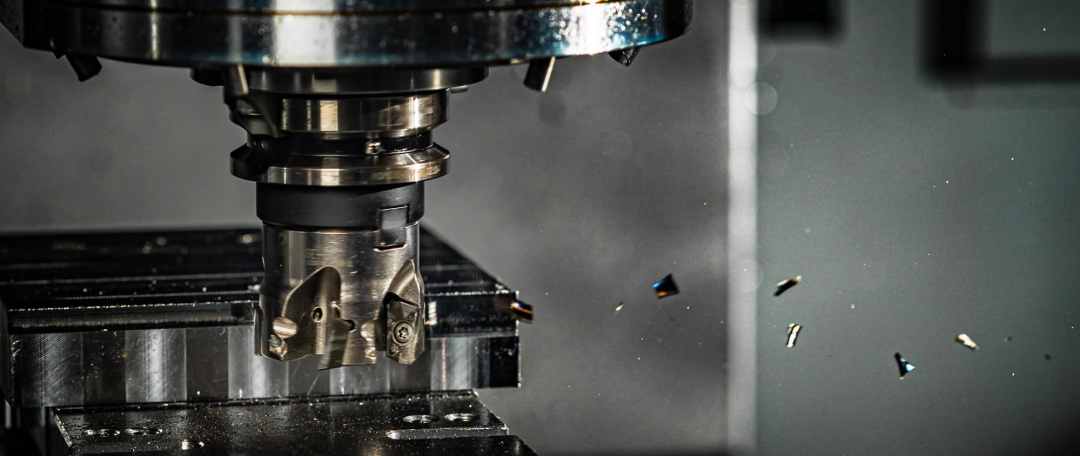

Step 1: Preparing the Milling Machine

Switch off and unplug your milling machine. Clean the areas where you will affix the DRO components to ensure proper adhesion.

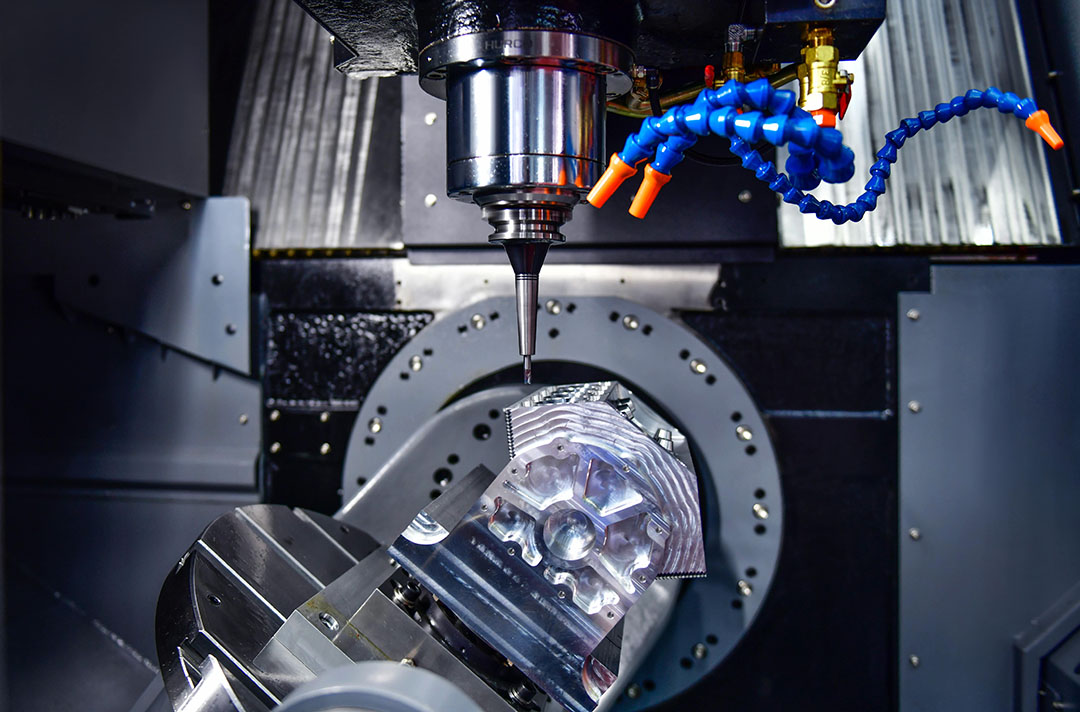

Step 2: Mounting the Scales

Begin with mounting the scales. Align them accurately and mark the drilling points. Drill holes as per the markings and secure the scales using screws.

Step 3: Installing the Readout Display

Next, mount the readout display in a location that’s easily visible and accessible. Use a mounting bracket if necessary.

Step 4: Connecting the Cables

Connect the scales to the readout display using the provided cables. Ensure all connections are secure and tidy up any excess wiring.

Step 5: Calibrating the DRO

Turn on the milling machine and follow the manufacturer’s guidelines to calibrate the DRO system. This usually involves zeroing the scales and inputting relevant measurement parameters.

Common Mistakes to Avoid

During the installation process, avoid common mistakes such as improper scale alignment, loose connections, and skipping the calibration step. These errors can lead to inaccurate readings and reduced efficiency.

Maintenance Tips

Regular maintenance of your DRO system ensures longevity and sustained precision. Always keep the scales clean, avoid excessive force on the readout display, and periodically check the connections.

Conclusion

Installing a DRO on a milling machine is a straightforward process when following the correct steps. This guide aims to simplify this task for you, ensuring a smooth installation. For more technical insights and industry standards, feel free to check out this external resource.

FAQs

1. What tools are required for installing a DRO?

The necessary tools include a DRO kit, wrenches, screwdrivers, drilling tools, and a mounting system.

2. How long does the installation process take?

The installation duration can vary, but typically it takes a few hours when following the step-by-step guide.

3. Can I install a DRO on any milling machine?

Yes, most DRO systems are designed for universal installation on various milling machines. However, always check compatibility beforehand.