Understanding how to learn CNC milling machine operations can be a game-changer for anyone in the manufacturing and industrial sectors. With the increasing implementation of CNC (Computer Numerical Control) machines, mastering their operations is becoming an essential skill. This article will guide you through the steps to become proficient in CNC milling. Whether you’re just starting out or advancing your skills, the tips and strategies covered will be invaluable.

Introduction to CNC Milling Machine Operations

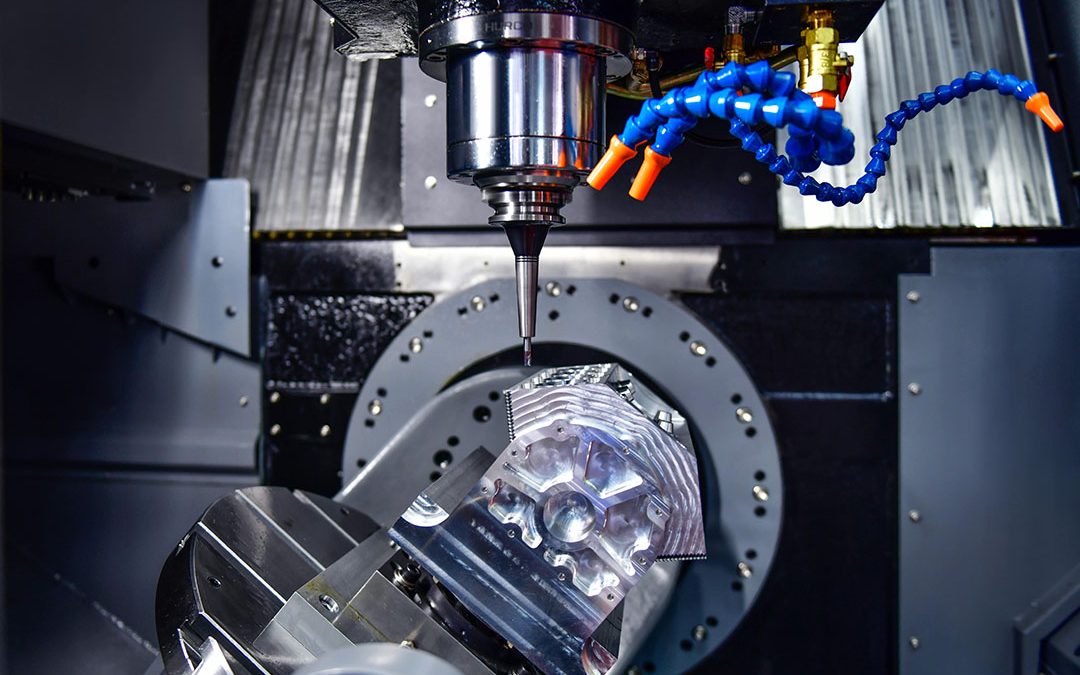

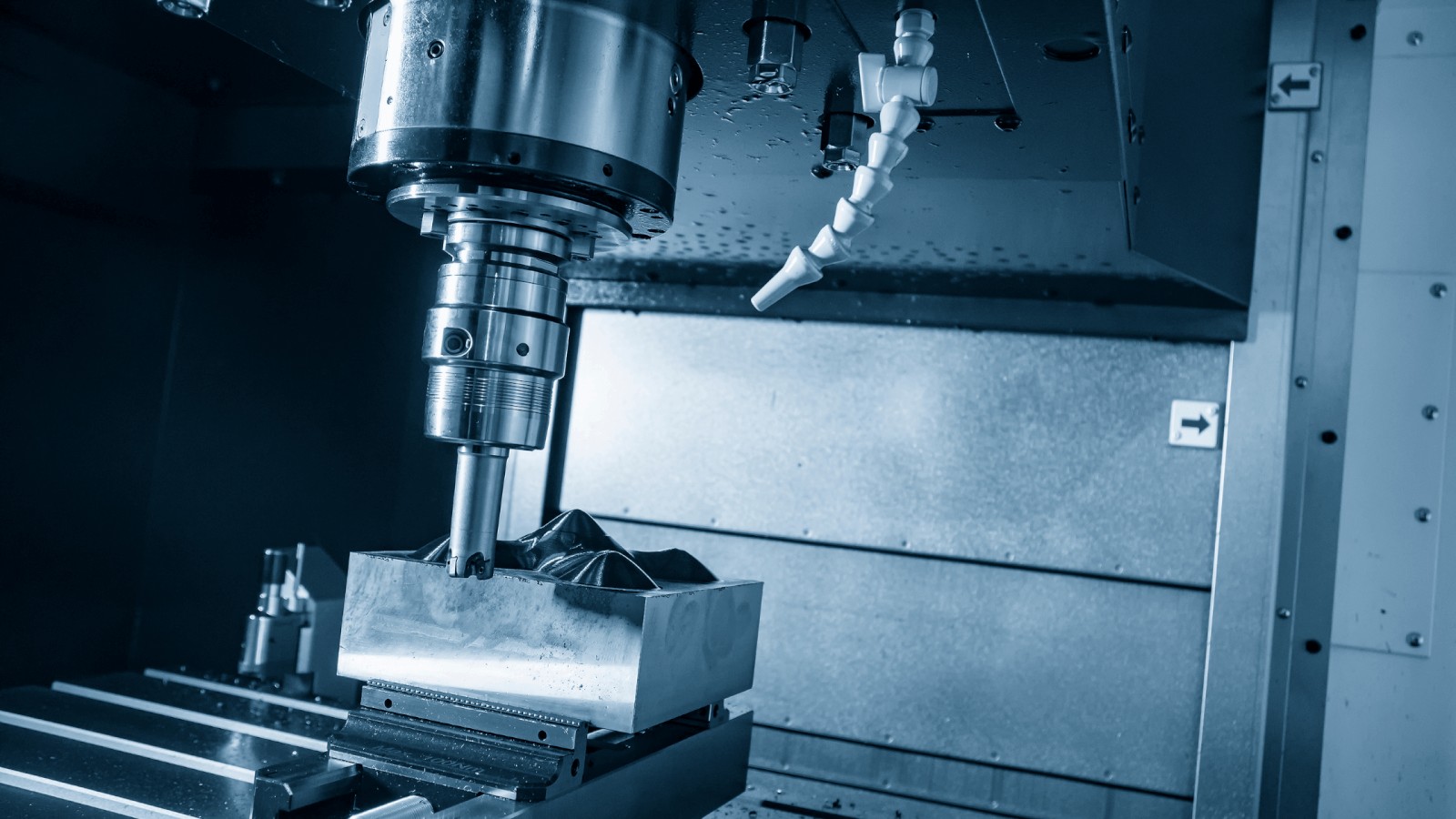

CNC milling machines are intricate pieces of machinery that enable precision shaping and cutting of materials. Learning to operate these machines involves understanding their components, programming languages, safety measures, and maintenance routines. Let’s dive into these topics in detail to ensure you gain a comprehensive understanding of CNC milling.

What is CNC Milling?

Before learning how to operate a CNC milling machine, it’s essential to understand what CNC milling is. CNC milling involves using a computer to control machine tools that cut or shape materials such as metal, wood, or plastic. The machines operate along multiple axes, which allows for more complex designs and precise cuts.

Understanding CNC Programming

CNC programming is crucial to mastering CNC milling operations. The process involves writing code that controls the machine’s movements and functions. Learning G-code, a language used to communicate instructions to CNC machines, is the first step. Numerous online resources and courses can help you get started with G-code.

Importance of Safety in CNC Milling

Safety is paramount when it comes to operating CNC milling machines. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection. Familiarize yourself with the machine’s emergency stop mechanism and ensure you know how to use it correctly.

Components of a CNC Milling Machine

Understanding the different components of a CNC milling machine is essential for proper operation. Key components include:

Spindle

The spindle holds and rotates the cutting tool. It is one of the most critical components of a CNC mill, as it directly impacts the quality of the cut.

Table

The table supports the material being milled. It moves along multiple axes to position the material accurately under the cutting tool.

Control Panel

The control panel allows the operator to interact with the machine, input commands, and execute milling operations.

How to Get Started with Learning CNC Milling Operations

Getting started with CNC milling operations involves several steps. Let’s break them down:

Enroll in Training Courses

The first step to learning CNC milling is to enroll in a training course. Many technical schools and community colleges offer CNC machining programs. Online platforms also provide courses for those who prefer to learn at their own pace.

Hands-On Practice

While theoretical knowledge is essential, hands-on practice is crucial. Many training programs offer opportunities to work with actual CNC machines to gain practical experience.

Advanced CNC Milling Techniques

Once you have mastered the basics, you may want to learn advanced CNC milling techniques:

5-Axis Milling

5-axis milling involves moving the cutting tool along five different axes, allowing for more complex and precise cuts. Mastering this technique can significantly improve your milling capabilities.

High-Speed Machining (HSM)

HSM is an advanced technique that involves using higher spindle speeds and feed rates to achieve faster material removal rates. This technique can improve productivity and efficiency in your milling operations.

Maintenance and Troubleshooting

Maintaining your CNC milling machine is crucial for ensuring its longevity and optimal performance. Regular maintenance tasks include:

Cleaning

Regularly clean your machine to prevent debris buildup, which can affect its performance and accuracy.

Lubrication

Lubricate moving parts to reduce friction and wear, ensuring smooth operation.

Troubleshooting Common Issues

Learning to troubleshoot common issues, such as misalignment or software glitches, can help you quickly resolve problems and minimize downtime.

Industry Applications of CNC Milling

CNC milling is used in various industries, including automotive, aerospace, electronics, and medical. Understanding these applications can give you insights into potential career opportunities and advancements in the field.

Enhancing Your Skills Through Certification

Pursuing certification can validate your skills and make you more competitive in the job market. Organizations such as the National Institute for Metalworking Skills (NIMS) offer certification programs for CNC operators.

The Future of CNC Milling

The future of CNC milling looks promising with advancements in industrial technology. Innovations such as AI-powered machines and smart manufacturing systems are expected to revolutionize the field. Staying updated on these trends can give you a competitive edge in your career.

Conclusion

Learning how to operate a CNC milling machine involves understanding its components, mastering programming, prioritizing safety, and gaining hands-on experience. By following these steps, you can become proficient in CNC milling operations and open the door to numerous career opportunities in various industries.

FAQs

1. What is the first step in learning CNC milling operations?

Enrolling in a training course is the first step in learning CNC milling operations. Many technical schools, community colleges, and online platforms offer comprehensive programs.

2. Why is G-code important in CNC milling?

G-code is a programming language used to control CNC machines’ movements and functions. Learning G-code is essential for writing accurate and efficient programs.

3. What safety measures should be taken when operating a CNC milling machine?

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection. Familiarize yourself with the machine’s emergency stop mechanism and ensure you know how to use it correctly.