Moving a milling machine is a meticulous task that necessitates careful planning and execution. Whether you are relocating a milling machine within your facility or transporting it to a new location, the process demands utmost precision. Understanding the technicalities involved can save you time, effort, and potential damage costs.

The importance of moving a milling machine correctly cannot be overstated. Mishandling can lead to mechanical issues, calibration problems, or even complete breakdowns. This article aims to provide a comprehensive guide on how to move a milling machine effectively and safely.

Why Moving a Milling Machine Requires Special Attention

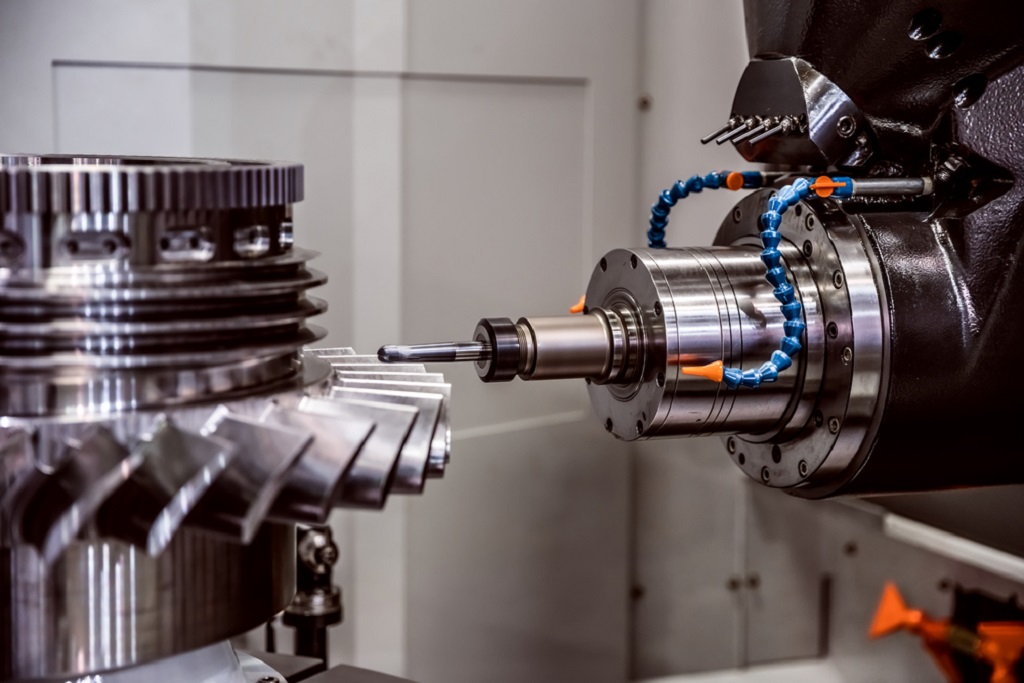

The milling machine is a cornerstone of many industries, including manufacturing, engineering, and metalworking. These machines are designed for precision tasks, making them delicate despite their robust appearance.

Understanding the Importance of Precision

Milling machines are characterized by their accuracy and reliability. Any misalignment during the moving process can disrupt the machine’s functionality.

Potential Risks Involved

Incorrectly moving a milling machine can cause significant damage. These risks include:

- Mechanical wear and tear

- Structural damage

- Loss of calibration

Preparation for Moving a Milling Machine

Preparation is the key to a successful moving operation. Before you start, ensure you have all the necessary information and tools.

Gathering Necessary Tools and Equipment

Ensure you have:

- Wrenches

- Screwdrivers

- Lifting equipment

- Supporting blocks

Inspecting the Milling Machine

Thoroughly inspect the milling machine for any pre-existing issues. Document these to avoid disputes later.

Step-by-Step Guide to Moving a Milling Machine

This section outlines the detailed steps you need to follow for a safe moving operation.

Step 1: Disconnect Power

Before you start any physical work, disconnect the machine from the power source. This ensures safety during the move.

Step 2: Secure Moving Parts

Lock all moving parts in place to prevent any unexpected movements that could cause damage.

Step 3: Lifting the Milling Machine

Use appropriate lifting equipment like a crane or forklift. Ensure the lifting points are secure.

Step 4: Transporting the Machine

Transport the milling machine carefully to its new location. Use supporting blocks to keep it stable.

Reinstallation at the New Location

Once you have moved the machine to its new location, the reinstallation process begins.

Step 1: Positioning the Milling Machine

Place the milling machine at its designated spot. Ensure it is level and stable.

Step 2: Reconnecting Power

Reconnect the machine to the power source. Double-check all connections to ensure safety.

Step 3: Calibration

Once installed, calibrate the milling machine to ensure it is functioning correctly. Test it with a simple task before resuming full operation.

Maintenance Tips After Moving a Milling Machine

After moving, proper maintenance is crucial to ensure the machine operates efficiently.

Regular Inspections

Conduct regular inspections to check for any issues that may have arisen during the move.

Lubrication

Lubricate all moving parts to prevent wear and tear.

Common Mistakes to Avoid

Knowing what to avoid can help you move your milling machine without any hiccups.

Neglecting to Plan

Without a plan, you may overlook essential steps, leading to potential damage.

Ignoring Safety Protocols

Always adhere to safety protocols to prevent accidents.

FAQ Section

Is it safe to move a milling machine without professional help?

While it’s possible, hiring professionals ensures the job is done safely and efficiently.

How much time is required for the entire moving process?

The time required depends on the size of the machine and the distance of the move.

What tools are essential for moving a milling machine?

Essential tools include wrenches, screwdrivers, lifting equipment, and supporting blocks.

For more information on milling machines, visit Milling Machines

Additionally, you can find more information on our website like advantages of CNC machines and wafer polishing inspection.