In today’s world, the CNC milling machine stands as a beacon of technological advancement. For Industry QA Professionals and beyond, understanding how to operate a CNC milling machine effectively is essential. This article will guide you through the intricacies of CNC milling, ensuring you are well-versed in its operation, benefits, and troubleshooting aspects.

A Brief Overview of CNC Milling Machines

CNC milling machines are integral to modern manufacturing. They offer tremendous precision and flexibility, making them delightedly approved in various industries.

What is a CNC Milling Machine?

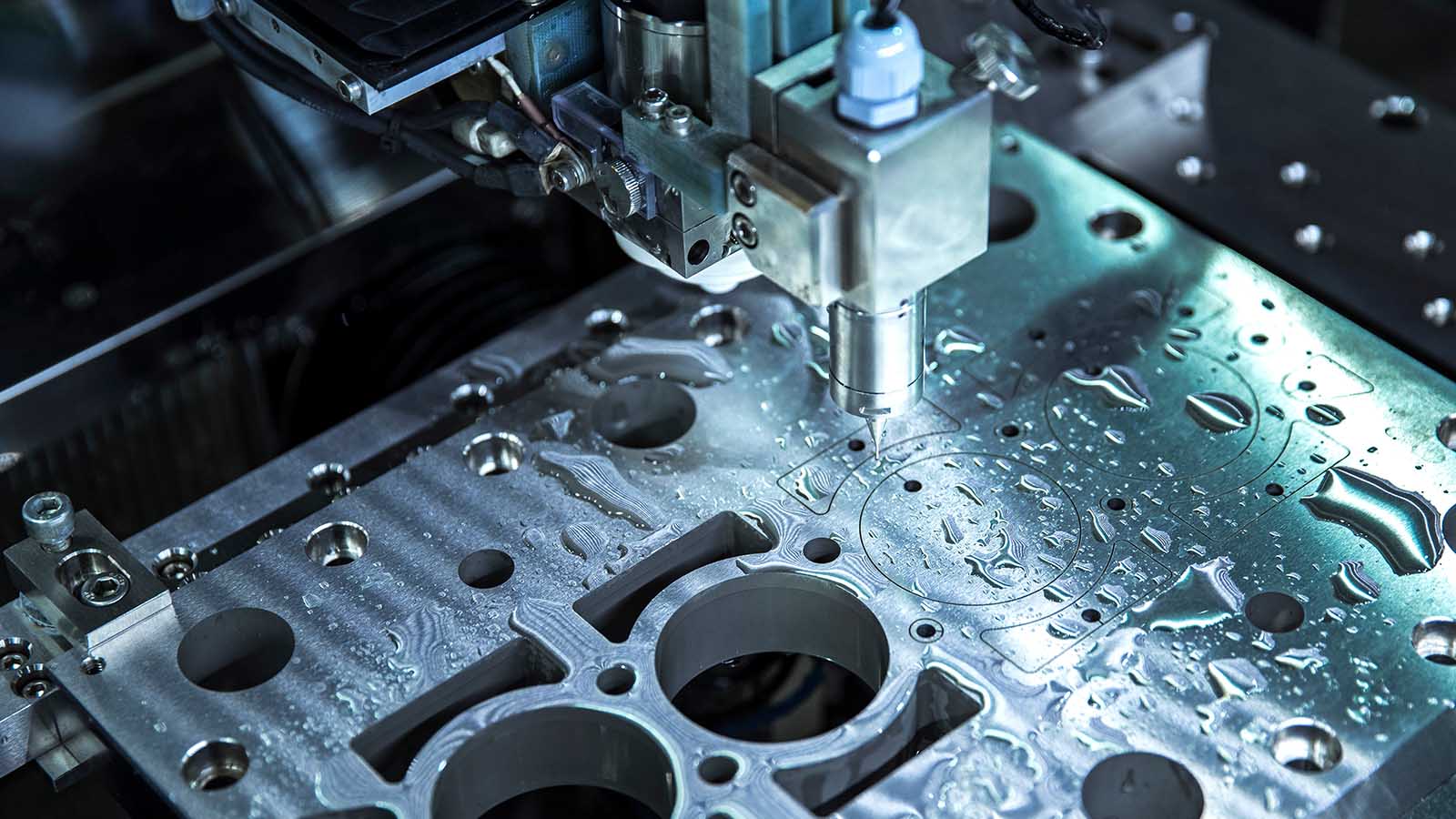

Before diving deep into how to operate a CNC milling machine, it’s crucial to understand what it is. Essentially, a CNC milling machine uses computer controls to cut, shape, and engrave materials. It’s a versatile tool, renowned for producing complex parts with high accuracy. For more detailed information, you can read this external resource on milling machines.

Components and Functions

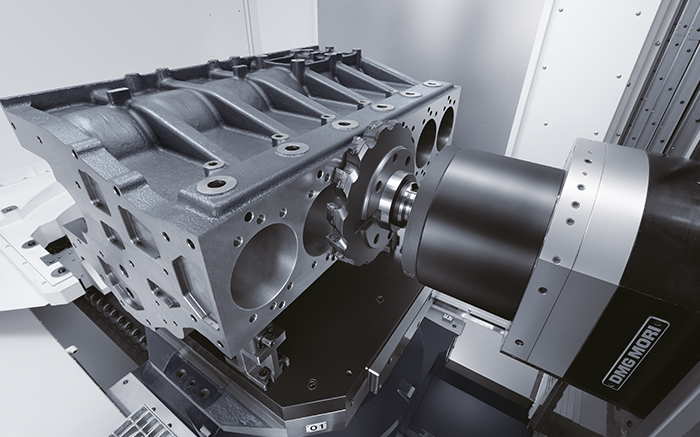

A CNC milling machine consists of various components such as the bed, the column, the spindle, and the control panel. Each part plays a significant role in ensuring the machine operates smoothly, delivering precise results.

Preparation Before Operating a CNC Milling Machine

Understanding the Software

The operation of a CNC milling machine begins with the software. Industry QA Professionals need to be proficient in software like CAD/CAM to design parts and translate these designs into precise milling instructions.

Setting Up the Machine

Setting up a CNC milling machine involves securing the material on the machine bed, ensuring all components are correctly configured, and running preliminary checks. This step is vital to ensure safety and accuracy.

Step-by-Step Guide on How to Operate a CNC Milling Machine

Step 1: Loading the Program

Begin by loading the CNC program. This program contains all the instructions the machine will follow. Ensure the software is free of errors and aligns with the desired output.

Step 2: Preparing the Machine

Inspect the machine for any visible issues. Load the material securely, adjust the tooling, and set the reference points.

Step 3: Running a Test

Run a simulation or a dry run. This step helps in identifying and rectifying potential errors before actual operation.

Step 4: Engaging the Machine

Initiate the machining process. Closely monitor the operation to ensure everything runs smoothly. Make adjustments as necessary.

Safety Tips When Operating a CNC Milling Machine

Personal Protective Equipment (PPE)

Always wear appropriate PPE such as safety glasses, gloves, and ear protection. Safety is paramount when operating powerful machinery.

Machine Maintenance

Regularly inspect and maintain your CNC milling machine. Ensure all components are in optimal condition to avoid accidents.

Troubleshooting Common Issues

Error Codes

Familiarise yourself with common CNC error codes and their resolutions. This knowledge will help in swiftly addressing issues as they arise.

Material Defects

Identify and rectify material-related issues. These can affect the quality of the final product.

FAQ Section

What is the primary function of a CNC milling machine?

A CNC milling machine’s primary function is to use computer controls to cut, shape, and engrave materials, achieving high precision and complex designs.

Is CNC milling difficult to learn?

With proper training and practice, operating a CNC milling machine becomes manageable. Familiarity with CAD/CAM software is beneficial.

How often should I maintain my CNC milling machine?

Regular maintenance is recommended to keep the machine in optimal condition and ensure safety. Check components periodically and address issues promptly.

Conclusion

The journey of understanding how to operate a CNC milling machine is both rewarding and essential for Industry QA Professionals. By following this guide, you will master the skills needed to leverage this tremendous technology in your career. For further reading, consider checking out additional resources such as this blog on CNC machines vs. lathes.