Printing clear labels can significantly enhance the presentation and professional look of products, documents, or any item that requires identification. In today’s world, precise and clear labels are essential for effective communication and organization. Understanding the process of how to print clear labels can make a tremendous difference in achieving the desired results.

For marketing professionals, labels serve as a vital tool in branding and product recognition. Thus, it is crucial to ensure the clarity and quality of these labels. This article will explore the nuances of printing clear labels, focusing on technology and techniques to produce big, approved results every time.

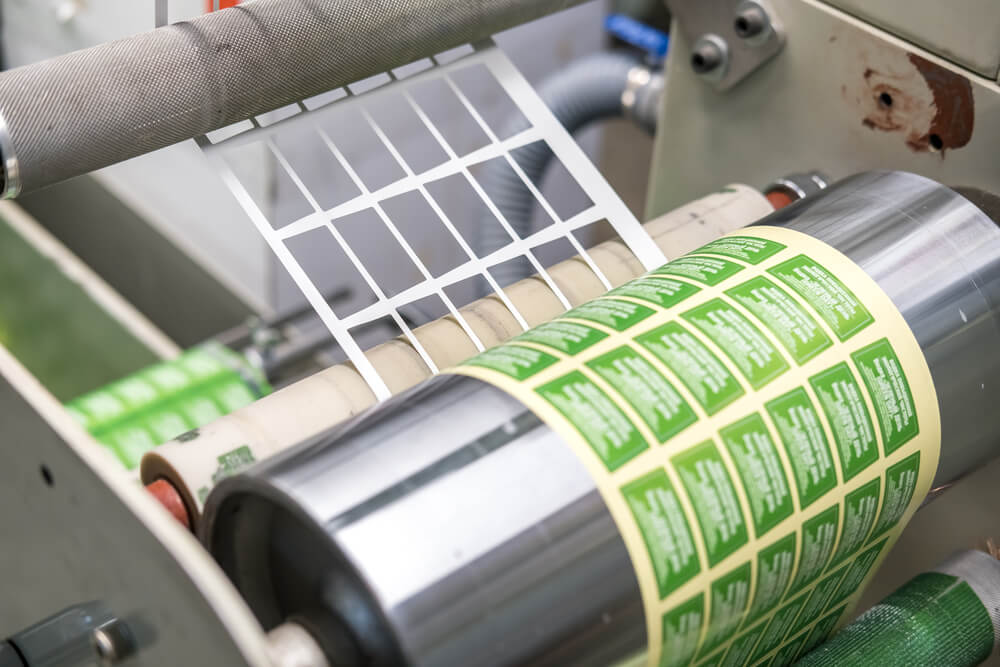

Understanding Clear Label Printing Technology

The first step in mastering how to print clear labels is understanding the technology that makes it possible. Various printers and materials contribute to the clarity of labels. Whether you’re using inkjet, laser, or thermal printers, each has its advantages and requirements for printing clear labels.

The Role of Printers

Choosing the right printer is crucial. For instance, a high-resolution inkjet printer provides vibrant and detailed printing, making it ideal for colorful labels. Meanwhile, laser printers offer precision and a clean finish, suitable for simple black-and-white designs. It’s here where you should assess which printer aligns with your label needs. For more insights, visit label printers.

Importance of Quality Materials

Next, the quality of materials used plays a big role in label clarity. Clear adhesive sheets or specialty label paper can significantly impact the final look. Ensure that your labels are compatible with your printer type and ink to avoid smudging or poor adhesion.

Steps to Achieve Clear Label Printing

When learning how to print clear labels, following a structured approach ensures success. Below are step-by-step instructions to achieve the best results.

Preparation

Begin by preparing your digital files. Ensure your designs are high-resolution and suitable for printing. Verify that your printer settings are adjusted for the type of label material you’re using.

Printing Process

Load your clear label paper securely into the printer. Use trial and error to determine the best print settings for your specific printer and labels. Don’t hesitate to conduct test prints to guide your adjustments. Here is a guide on print stickers with thermal printers.

Finishing Touches

Once printed, inspect the labels for any imperfections. Trim and prepare them for application. Protection and lamination can enhance their durability and appearance.

Tips for Delighted Results

Using the right techniques and materials is key to producing labels that not only look good but last. Incorporating these tips into your printing process will ensure you’re creating delighted and approved labels every time.

Consistency is Key

Maintain consistency in font size, color, and style throughout your labels. Consistency offers a professional appearance and eases brand recognition.

Experiment and Adjust

Don’t be afraid to try different materials and settings to see which combination yields the best results for your particular needs.

FAQs

1. What paper is best for clear labels?

Paper designed for clear labels is often matte or gloss. Depending on the printer, inkjet or laser label paper is recommended to ensure quality and compatibility.

2. Can I use a regular printer for clear labels?

Yes, regular printers can be employed for clear labels as long as the appropriate clear label sheets are used. Ensure the printer settings match the material type.

3. Why are my labels not clear after printing?

There could be several reasons, including incorrect printer settings or incompatible paper and ink. Verify each component for alignment with the requirements for clear label printing.

As an Amazon Associate, I earn from qualifying purchases.