Tramming a milling machine is an essential process that ensures the spindle and the table are perpendicular. This ensures high-quality machining and precision. If you are an industry QA professional, understanding how to tram a milling machine is crucial to achieving impeccable outcomes in your projects.

Today, we’re going to dive deep into this topic and provide you with expert-approved tips to help you master the tramming process.

Why Tramming is Critical for Milling Machines

Tramming is a foundational element in ensuring your milling machine operates accurately. Without proper tramming, you risk producing parts that are off-spec and poor in quality.

Tools You’ll Need for Tramming

- Dial Indicator

- Tramming Gauge

- Wrenches

- Calibration Squares

Preparation Before Tramming

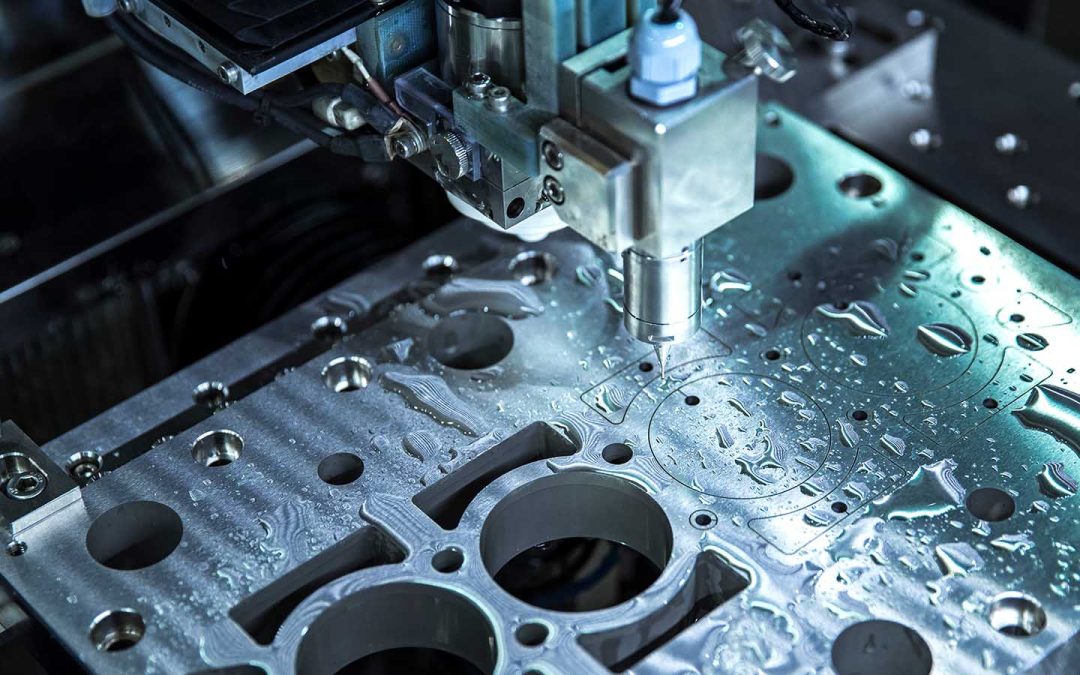

Step 1: Clean the Machine

Before you start the tramming process, ensure that your milling machine is clean. This includes removing any swarf or debris from the spindle and table.

Step 2: Secure the Table

Ensure that the table is both clean and secure. Any movement during tramming will affect the precision of the process.

Step 3: Install the Tramming Tool

Place the tramming tool such as a dial indicator into the spindle or collet.

The Tramming Process

Step 1: Position the Indicator

Place the dial indicator so that its tip touches the table of the milling machine. Zero the indicator.

Step 2: Rotate the Spindle

Gently rotate the spindle around the table. Watch the reading on the dial indicator until you’ve checked the entire table.

Step 3: Adjust the Head

If the indicator shows any deviation, its time to adjust the head of the milling machine. Use wrenches to make these adjustments until the indicator reads zero all the way around.

Common Mistakes in Tramming

Even experienced professionals make mistakes. Here are some pitfalls to avoid:

- Not cleaning the machine properly.

- Failing to secure the table adequately.

- Ignoring subtle deviations on the dial indicator.

Maintenance Tips for Long-term Accuracy

Maintenance is crucial for long-term accuracy. Regularly check the tramming of your machine, especially after moving or repairing it.

Tramming Different Types of Milling Machines

Different milling machines have various tramming requirements. Heres a brief overview:

Vertical Milling Machine

Most commonly used, these machines typically require tramming in two directions.

Horizontal Milling Machine

These machines often require tramming in a single direction.

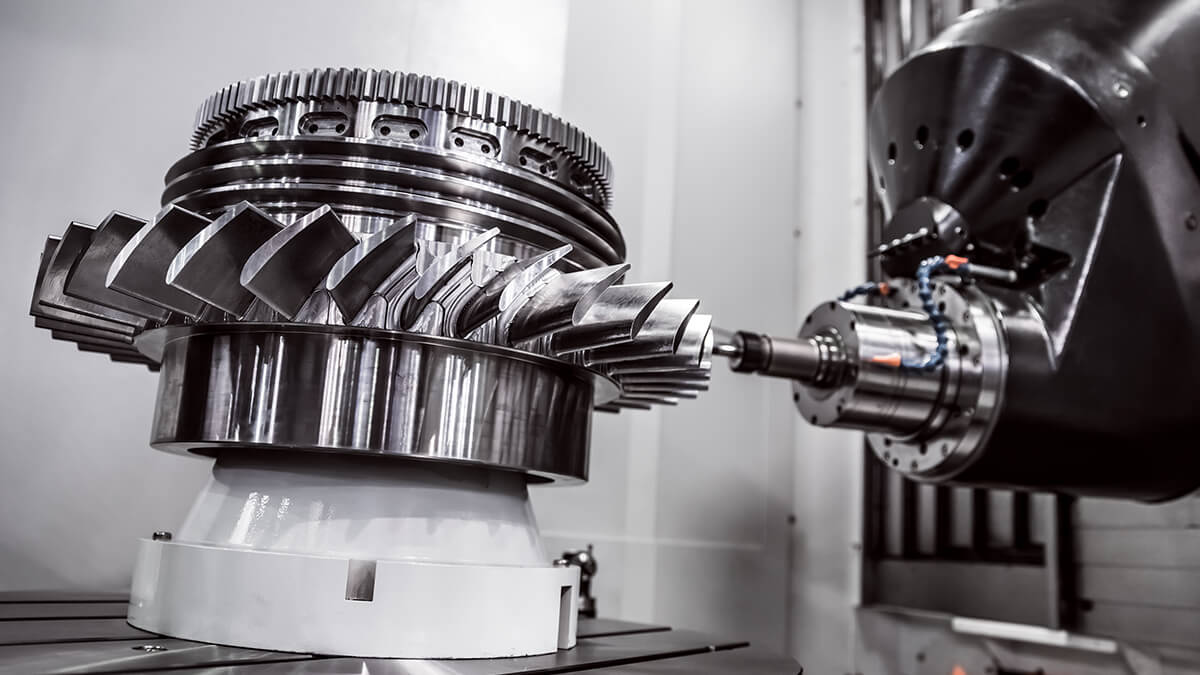

CNC Milling Machine

For CNC mills, you might use digital or software-based tools for tramming.

Advanced Tramming Techniques

Integrating advanced technologies such as laser alignment tools can significantly enhance the tramming accuracy.

Importance of Spindle Alignment

Spindle alignment is another crucial factor. Proper spindle alignment ensures that cutting tools remain perpendicular to the table.

FAQ

What happens if I don’t tram my milling machine?

If you dont tram your milling machine, youll likely produce inaccurate and low-quality parts.

How often should I tram my milling machine?

Its recommended to tram your machine after any significant movement or repair, and periodically during regular maintenance.

Can I use software tools for tramming?

Yes, advanced CNC machines often support software-based tramming processes.

Conclusion

Understanding how to tram a milling machine is essential for any industry QA professional. This comprehensive guide can aid in ensuring your milling processes are both accurate and efficient.

For further intricate details, you can find more information on High-Speed Paint Analysis, Genetic Analysis, and Semiconductor Inspection.

For further reading on milling machines, visit CNC Masters.