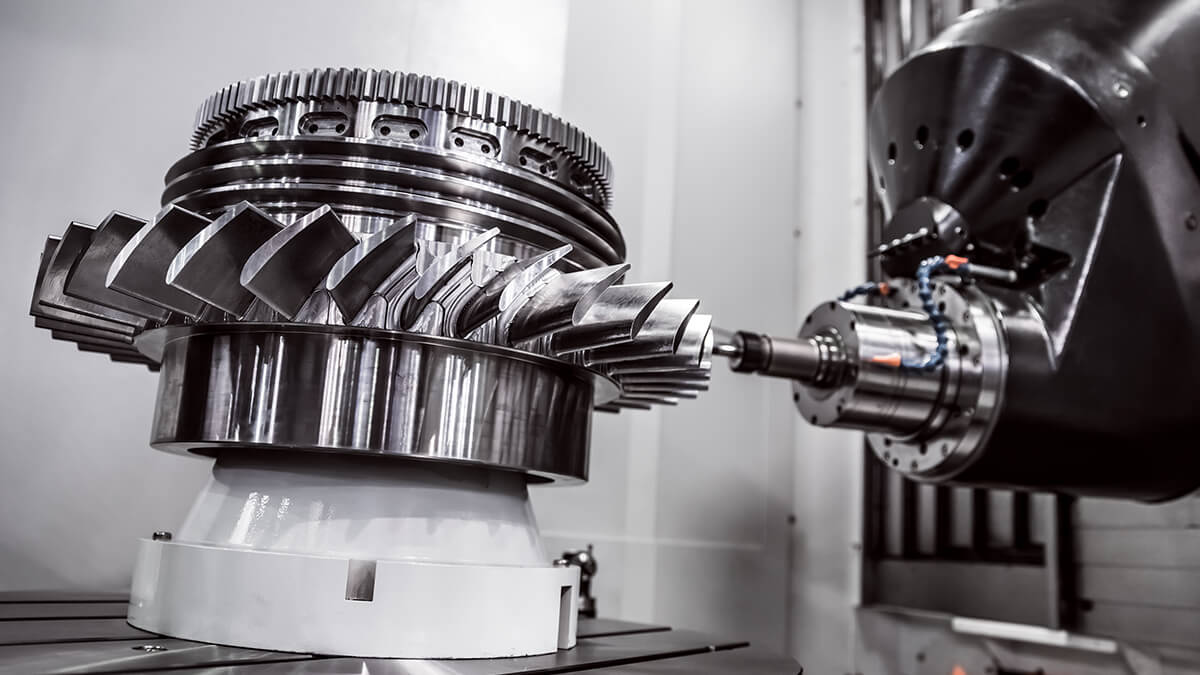

Unloading a milling machine is a vital task that many Industry QA professionals encounter in their line of work. It’s here where precision and care are necessary to ensure that the machine and the operator are safe from any harm. This article delves into ‘how to unload a milling machine’ with a step-by-step guide that makes the process straightforward and efficient.

We’ll cover important safety measures, the right equipment needed, and tips for handling different types of milling machines. This comprehensive guide will arm you with knowledge and confidence, ensuring that every unloading operation is conducted with tremendous precision and care.

Initial Preparations for Unloading a Milling Machine

Necessary Safety Equipment

Before attempting to unload a milling machine, it is crucial to gather the necessary safety equipment. This typically includes:

- Protective Gloves

- Safety Glasses

- Hard Hat

- Steel-toe Boots

- High-visibility Vest

Ensuring that every worker has access to this equipment can prevent accidents and injuries.

Inspecting the Work Area

Inspecting the work area is another vital step. The area should be clean, free of obstructions, and capable of supporting the weight of the milling machine and the unloading equipment. Double-check the floor conditions, lighting, and ensure that there are no materials that could pose a tripping hazard.

Equipment Needed for Unloading a Milling Machine

Having the right equipment makes the unloading process more efficient and reduces risks. Here are the primary tools you will need:

Forklifts and Cranes

Forklifts and cranes play a crucial role in the process of unloading heavy machinery like a milling machine. Ensure that the operators are well-trained and certified to handle these machines.

Pallet Jacks

Pallet jacks are essential for maneuvering the milling machine once it has been unloaded. They allow for precise and controlled movement.

Step-by-Step Guide to Unloading a Milling Machine

Step 1: Prepare the Machine

Begin by preparing the milling machine for unloading. Secure all moving parts and remove any accessories or tooling that could become dislodged during transport.

Step 2: Position the Unloading Equipment

Position your forklift or crane so that it can safely lift the milling machine. Make sure that the equipment is on stable ground and there is enough space for maneuvering.

Step 3: Attach the Lifting Straps

Attach the lifting straps securely to the designated lift points on the milling machine. Use high-quality, rated lifting straps to ensure the machine is supported evenly during the lift.

Step 4: Lift and Lower the Machine

Gradually lift the milling machine, maintaining constant communication between the operator and the ground crew. Once the machine is lifted safely, navigate to the designated drop-off point and lower it slowly onto the prepared surface.

Step 5: Final Positioning

Using pallet jacks, position the milling machine precisely where it is intended to remain. Double check its stability and make necessary adjustments to ensure it is level and secure.

Common Challenges and How to Overcome Them

Navigating Tight Spaces

One common challenge is dealing with tight spaces. Using the right equipment, such as smaller forklifts or manual pallet jacks, can help navigate these areas more effectively.

Ensuring Load Stability

Ensuring that the load remains stable during the entire unloading process is paramount. Double check all connections and engage in constant communication with the team to monitor the load’s stability.

Handling Different Types of Milling Machines

Different types of milling machines may present unique challenges. Whether you’re dealing with a horizontal, vertical, or CNC milling machine, understanding the specific requirements and guidelines for each can simplify the task.

Best Practices for a Safe Unloading Process

Adopting best practices is essential for a safe unloading process.

Effective Communication

A key best practice is maintaining effective communication. All team members should be aware of their roles and responsibilities, and regular briefings can help ensure everyone is on the same page.

Regular Training

Conduct regular training sessions for all personnel involved in the unloading process. This ensures that everyone is equipped with the correct knowledge and skills to perform their duties safely.

Conclusion

Unloading a milling machine involves a series of well-coordinated steps and the right equipment. By following the guidelines and best practices outlined in this article, Industry QA professionals can ensure a safe and efficient process. Equip yourself with the right knowledge, be diligent with safety measures, and you’ll find unloading a milling machine to be a tremendously manageable task.

Frequently Asked Questions (FAQs)

Q1: What safety measures should be taken when unloading a milling machine?

Answer: Ensure all team members wear appropriate safety gear such as protective gloves, safety glasses, and steel-toe boots. Maintain clear communication and inspect the work area for potential hazards.

Q2: What equipment is essential for unloading a milling machine?

Answer: Essential equipment includes forklifts, cranes, pallet jacks, and rated lifting straps. Ensure all equipment operators are certified and well-trained.

Q3: How can I ensure the stability of the load during unloading?

Answer: Use high-quality lifting straps and maintain constant communication with the ground crew to monitor the load’s stability. Double-check all connections and make necessary adjustments during the process.

External References

For more information on milling machines, visit this detailed guide.

Internal Links

Learn more about related topics: