For industry QA professionals, understanding how to use a drill press is essential. This comprehensive guide will provide you with all the insights and techniques to master this valuable tool, ensuring precision and safety in your drilling projects.

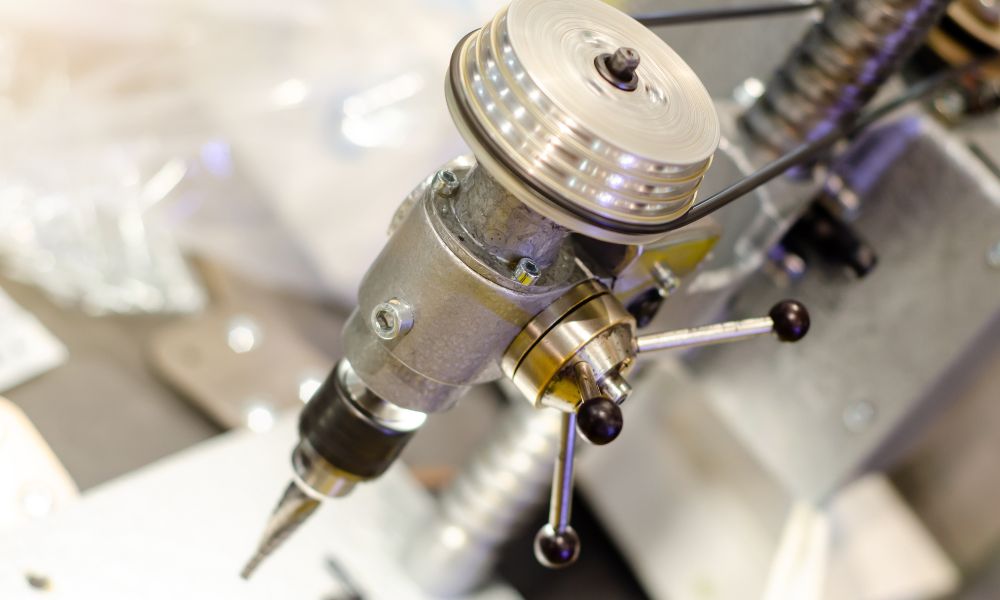

What is a Drill Press?

A drill press is a fixed-style power tool specifically designed for drilling precise holes. Unlike handheld drills, drill presses offer higher accuracy and control, making them essential in professional workshops.

Parts of a Drill Press

Familiarizing yourself with the different parts of a drill press will help you use the tool more effectively:

- Base: Provides stability and support.

- Column: A vertical support that keeps the drill press steady.

- Table: The surface where you place your material.

- Spindle: Holds the drill bit and rotates it.

- Chuck: Secures the drill bit in the spindle.

- Feed Lever: Allows the user to lower or raise the drill bit.

Setting Up Your Drill Press

Before you start using your drill press, its crucial to set it up correctly to ensure precision and safety.

Choosing the Right Location

Place your drill press on a sturdy workbench with enough space around it. Ensure adequate lighting and easy access to electrical outlets.

Assembling the Drill Press

Follow the manufacturers instructions for assembling your drill press. Ensure all components are securely fastened and aligned.

Using a Drill Press Safely

Safety should always be a priority when using a drill press. Here are some essential safety precautions:

Wearing Safety Gear

Always wear safety glasses to protect your eyes from flying debris. Use ear protection if necessary, as drill presses can be noisy.

Securing Your Material

Firmly clamp your material to the table to prevent it from moving during drilling. Always use safety clamps for added security.

Operating the Drill Press

Now that your drill press is set up and safety guidelines are in place, its time to start drilling.

Choosing the Right Drill Bit

Select the appropriate drill bit for your project. Ensure the bit is sharp and suitable for the material youre drilling.

Setting the Speed

Adjust the drill press speed based on the material and drill bit. Lower speeds are suitable for harder materials, while higher speeds work well for softer materials.

Drilling Techniques and Tips

Marking Your Material

Use a center punch to mark the exact spot where you want to drill. This ensures accuracy and prevents the bit from wandering.

Starting the Drill

Align the drill bit with your mark and lower the feed lever slowly. Apply steady pressure without forcing the drill bit.

Drilling Holes

Drill at a consistent speed, making sure to lift the drill bit occasionally to clear out debris. This prevents overheating and ensures a clean hole.

Maintaining Your Drill Press

Regular maintenance is crucial for the longevity and performance of your drill press.

Cleaning and Lubricating

Regularly clean your drill press to remove dust and debris. Lubricate moving parts to prevent wear and tear.

Inspecting for Damage

Frequently inspect your drill press for any signs of damage or wear. Replace worn-out parts promptly to maintain optimal performance.

Advanced Drill Press Techniques

Drilling at Angles

Adjust the table to drill at specific angles. This is useful for creating angled holes for joints and other purposes.

Using Jigs

Jigs are helpful for repetitive drilling tasks. They ensure consistency and speed up the process.

Common Mistakes to Avoid

Understanding common mistakes can help you prevent them and improve the quality of your work.

Overheating the Bit

Applying too much pressure or drilling too fast can cause the drill bit to overheat, leading to dullness and damage.

Inaccurate Measurements

Always double-check your measurements and markings before drilling to avoid mistakes.

FAQs

What materials can I drill with a drill press?

With the right drill bit, a drill press can handle various materials, including wood, metal, and plastic.

How do I choose the right drill bit?

Consider the material youre drilling and the hole size you need. Consultmanufacturer guidelines for recommendations.

How often should I maintain my drill press?

Regular maintenance should be performed after every use. Thorough cleaning and inspection are recommended every few months.

For more detailed instructions and advanced techniques, refer to the [Harvard drill press guide](https://www.ehs.harvard.edu/sites/default/files/machine_shop_safety_osha_guidance_drill_press.pdf?rel=nofollow).

Additional Resources

For more information on drill presses and other high-speed inspection technologies, visit [Semiconductor Wafer Polishing Inspection](https://strobox.ai/high-speed-semiconductor-wafer-polishing-inspection-2). Discover the impact of drill presses on [Event Detection](https://strobox.ai/advanced-stroboscopic-event-detection-in-semiconductor-wafer-polishing) and find advanced solutions for [High-Speed Manufacturing](https://strobox.ai/high-speed-semiconductor-manufacturing-inspection/).