Introduction

Many individuals are often intrigued by the possibility of utilizing their drill press in a way that it resembles a milling machine. The transformation of a drill press into a milling machine is indeed an exciting endeavor that promises potential cost savings and versatility. A traditional drill press is primarily used for drilling holes, but with certain adjustments, it can serve as a viable substitute for a milling machine. This article provides an in-depth, step-by-step guide on how to use a drill press as a milling machine, along with the necessary tools and techniques.

Understanding the Basics

What is a Drill Press?

A drill press is a fixed-style drilling machine that can be mounted on a stand or bolted to the floor or workbench. It consists of a base, column, spindle, and drill head. The primary function of a drill press is to perform precise holes in various materials by moving the spindle vertically.

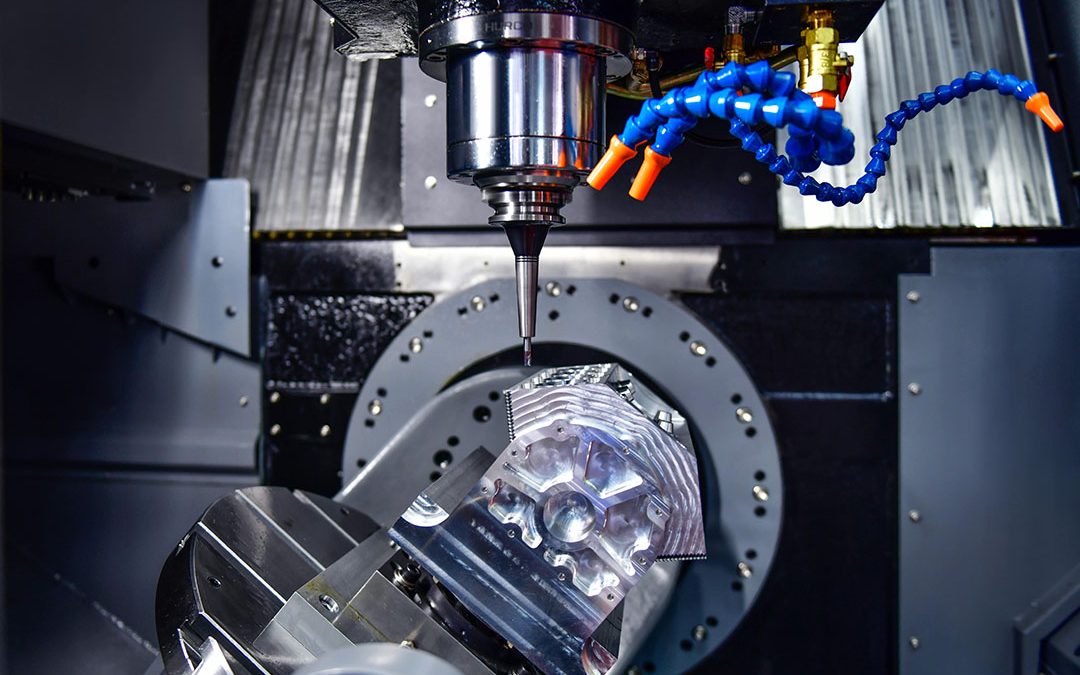

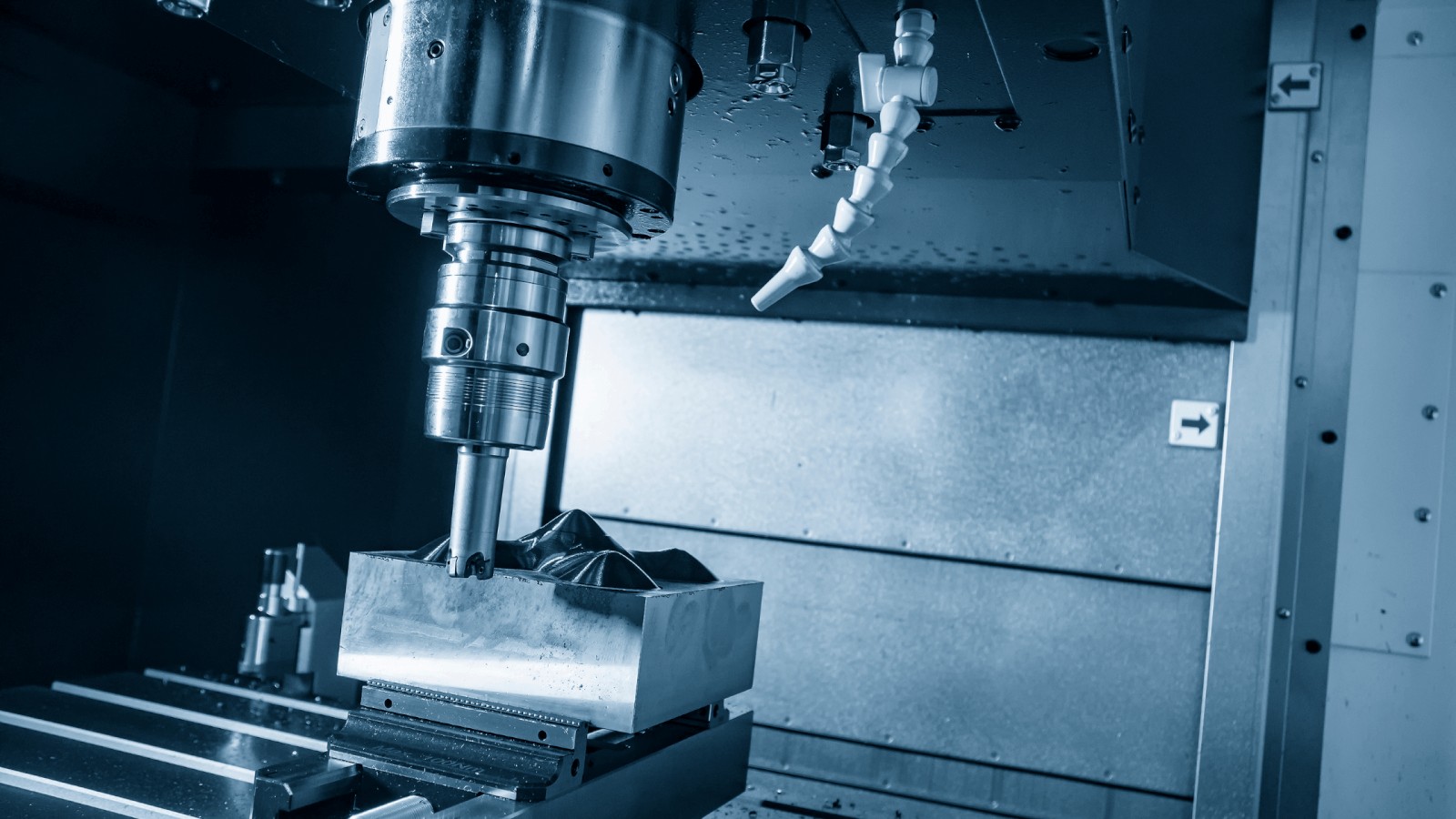

What is a Milling Machine?

A milling machine is used for cutting and shaping materials. It has a rotating cutting tool that moves along multiple axes, creating intricate shapes and designs. Milling machines are more versatile than drill presses, allowing for more complex operations.

Benefits and Limitations

Why Use a Drill Press as a Milling Machine?

One of the significant benefits of using a drill press as a milling machine is cost efficiency. Drill presses are generally less expensive than milling machines, making this approach economically viable for hobbyists and small-scale operations.

Limitations

While a drill press can mimic some functions of a milling machine, its essential to acknowledge its limitations. Drill presses are not designed for lateral pressure, which can lead to inaccuracies and potential damage to the machinery.

Transforming Your Drill Press

Step-by-Step Guide

- Choose the Right Drill Press: Not all drill presses can be converted into milling machines. Opt for a high-quality, sturdy drill press with a robust motor.

- Install a Milling Table: A milling table provides stability and accurate movements along the X and Y axes.

- Secure the Workpiece: Use a vise or clamps to hold the workpiece firmly in place. This is crucial for precision and safety.

- Select Appropriate Milling Cutters: Choose milling cutters that are compatible with your drill press and the material you’re working with.

- Adjust the Speed: Set the spindle speed according to the material and cutter specifications.

Safety Precautions

Essential Safety Tips

Safety should always be a priority when operating machinery. Here are some essential safety tips:

- Wear safety goggles and gloves.

- Ensure the drill press is securely anchored.

- Use guards and shields to protect from flying debris.

- Never overload the machine beyond its capacity.

- Disconnect the power when changing tools or making adjustments.

Enhanced Performance Tips

Fine-Tuning for Accuracy

For enhanced performance, fine-tuning is necessary. Make sure the spindle is well-aligned with the table, and the machine is properly lubricated to reduce friction and wear.

Regular Maintenance

Regular maintenance, such as cleaning and lubrication, ensures the longevity and efficiency of your drill press. Check for wear and tear and replace any damaged parts promptly.

Real-World Applications

Practical Uses

The ability to use a drill press as a milling machine opens up a wide range of applications. From crafting intricate designs in woodworking to creating precise metal components, the versatility is tremendous.

Choosing the Right Tools

Essential Tools and Accessories

To successfully convert a drill press into a milling machine, certain tools and accessories are indispensable:

- Milling table

- Vise or clamps

- Cutter set

- Protective gear

Conclusion

Using a drill press as a milling machine is a practical and cost-effective alternative for those who need precise and versatile machining capabilities. By following the steps outlined in this guide, you can achieve satisfactory results. Remember always to prioritize safety and regular maintenance to ensure the longevity of your equipment. For further information, you might find this external link useful. Additionally, you can explore more about inspection techniques and advanced event detection for further insights.

FAQ

Can I mill all types of materials with a drill press?

While a drill press can handle various materials, it is essential to understand the limitations. Soft materials like wood and plastic are more suitable, whereas hard metals may pose challenges and require special cutters.

How do I ensure precision when using a drill press as a milling machine?

Precision can be achieved by ensuring that the drill press is well-anchored, the workpiece is securely clamped, and the correct speed and cutters are used. Regular maintenance and fine-tuning also play a crucial role in maintaining accuracy.

Is it safe to use a drill press as a milling machine?

Although it is possible to use a drill press as a milling machine, it is vital to follow safety protocols to prevent accidents. Always wear protective gear, ensure the machine is properly secured, and avoid overloading the machine.