Using a manual milling machine can seem daunting at first, especially if you are new to machining. However, with technology-approved tips and a proper understanding, you can perform tremendous tasks with these machines. This guide is designed to help you learn and master the process of operating a manual milling machine efficiently and safely.

Introduction to Manual Milling Machines

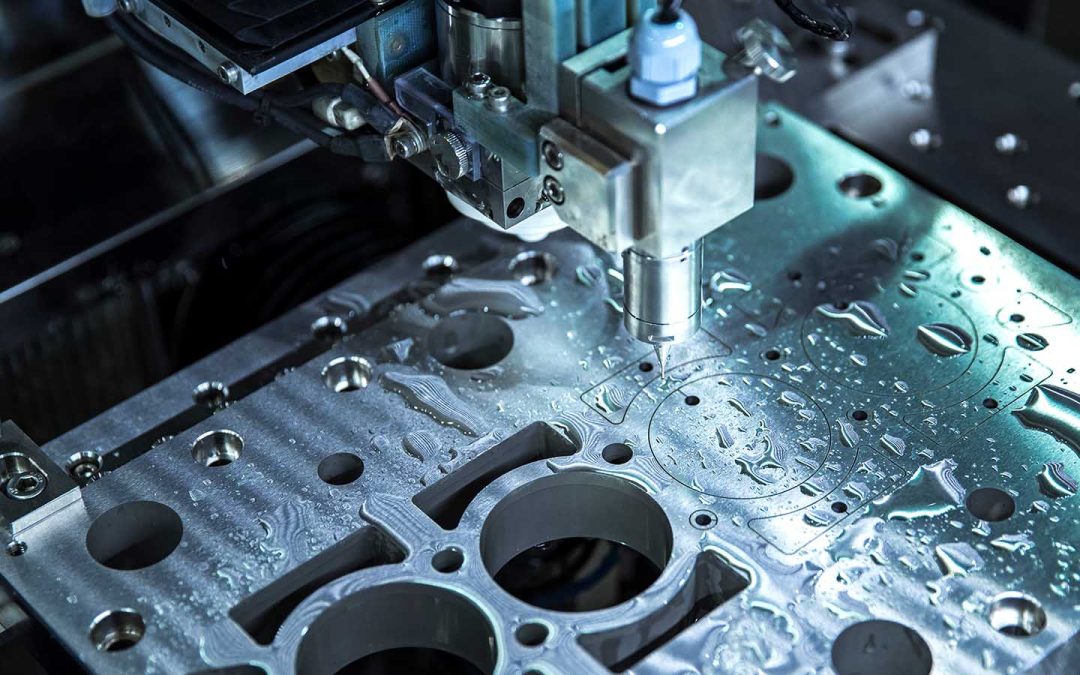

A manual milling machine is a versatile piece of equipment that is fundamental in the machining industry. These machines are used to shape solid materials like metal and wood. Unlike automated milling machines, manual versions rely solely on human operators to control the cutting processes.

Components of a Manual Milling Machine

- Spindle

- Table

- Column

- Saddle

- Knee

Understanding the Spindle

The spindle is the heart of the milling machine. It rotates the cutting tool at high speeds, allowing it to cut into the material.

Role of the Table

The table holds the material in place. It can be moved along different axes to position the material correctly.

Preparing for Milling

Safety First

Before operating a manual milling machine, wear the appropriate safety gear, including safety glasses and hearing protection. Ensure the machine is in proper working condition.

Material Preparation

Make sure your material is properly prepared and securely clamped onto the table.

Basic Operations of a Manual Milling Machine

Setting Up the Machine

Start by cleaning the table and fixing the workpiece. Ensure all tools and materials are within easy reach.

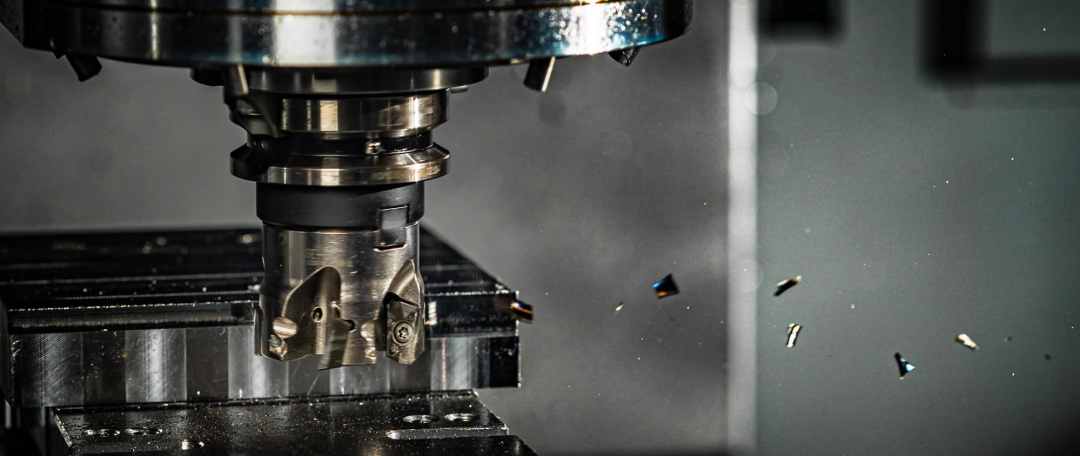

Adjusting the Spindle Speed

The spindle speed must be adjusted according to the material and the type of cut required.

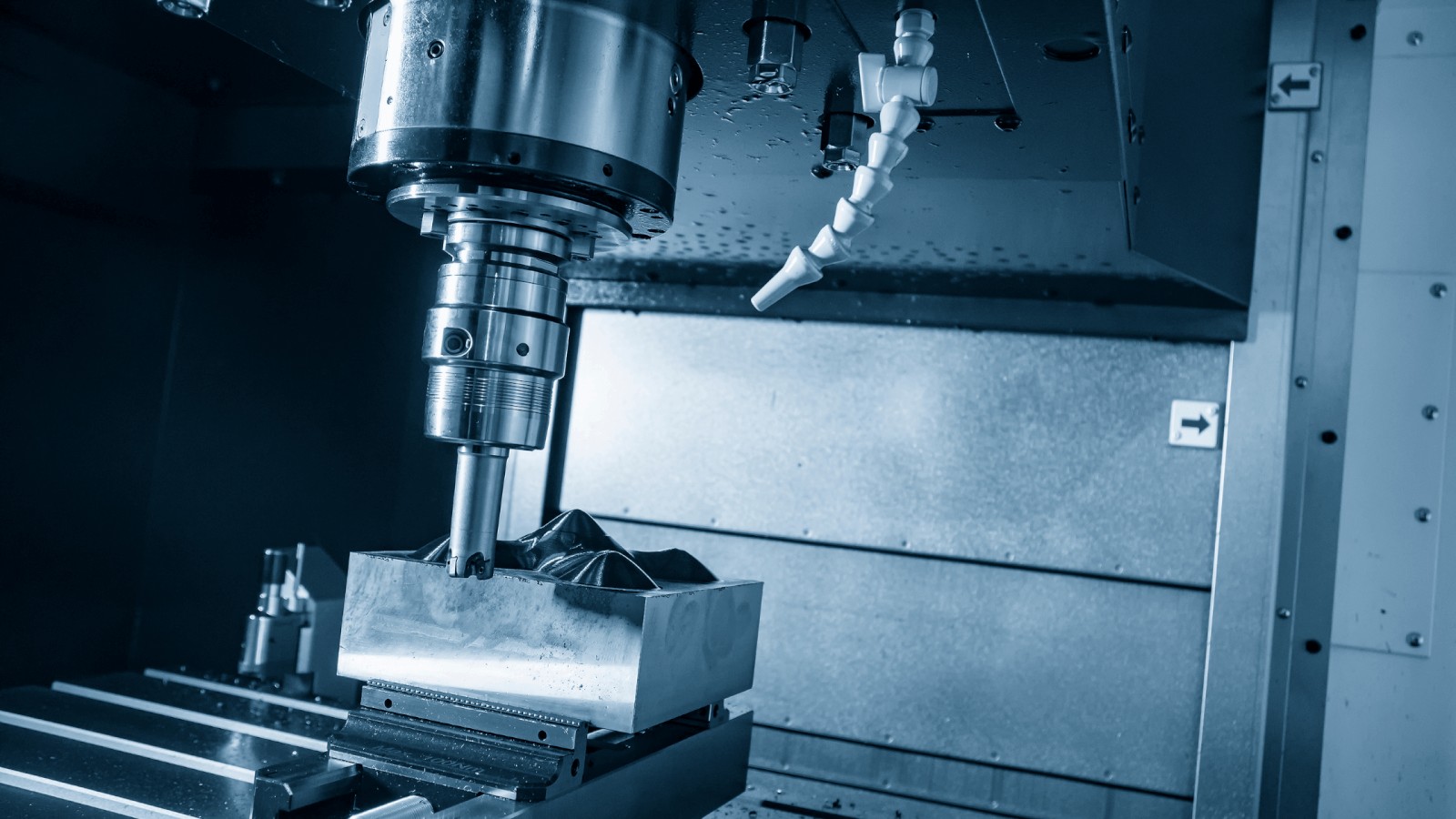

Positioning the Cutting Tool

Align the cutting tool with the workpiece using the handwheel.

Advanced Milling Techniques

Face Milling

Face milling involves cutting a flat surface on the material. It’s useful for creating a smooth, finished surface.

Slot Milling

This technique is used to create slots or grooves in the material.

Common Mistakes to Avoid

- Not using the correct spindle speed

- Failing to secure the material properly

- Overloading the machine

Maintenance of Manual Milling Machines

Regular Cleaning

Keep the machine clean to ensure smooth operation.

Lubrication

Regularly lubricate the moving parts to prevent wear and tear.

Conclusion

Mastering the use of a manual milling machine is an invaluable skill for industry QA professionals. By following the tremendous tips and techniques outlined in this guide, you can ensure that you are using the machine efficiently and safely, leading to high-quality output.

FAQs

What is a manual milling machine?

A manual milling machine is a machining tool that is operated by hand, used to shape solid materials.

How do I set up a manual milling machine?

Start by cleaning the table, securing the workpiece, and ensuring all necessary tools are within reach.

What are the common mistakes to avoid when using a manual milling machine?

Common mistakes include not using the correct spindle speed, failing to secure the material properly, and overloading the machine.

For more in-depth information on manual milling machines, visit this informative article.

Check out High-Speed Analysis for related topics.

Improve your machining skills by reading about Wafer Polishing.

For more practical machining insights, explore this resource on Manual Lathes.