The Tremendous and innovative use of a rotary table on a milling machine can significantly elevate your machining capabilities. Whether you’re a seasoned machinist or a soon-to-be expert, understanding how to properly use a rotary table can enhance precision and efficiency in various machining tasks. This article provides a comprehensive guide on how to use a rotary table on a milling machine, detailing its importance and offering practical tips to get you started.

What is a Rotary Table?

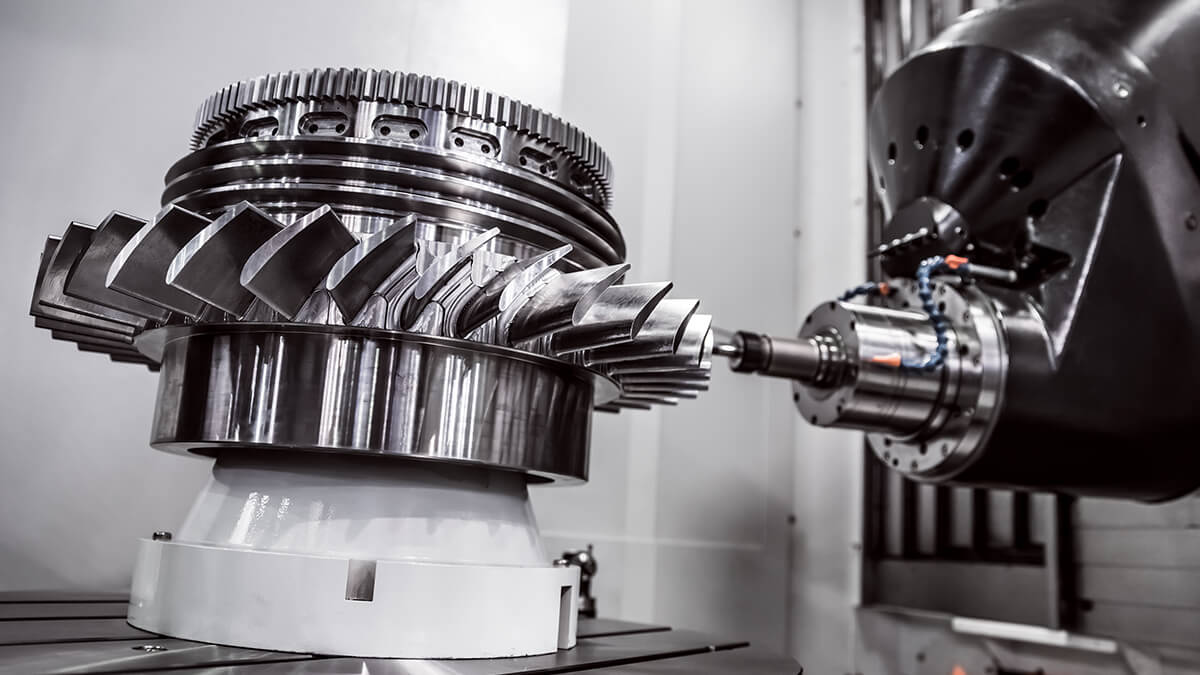

A rotary table is a precision work positioning device used in metalworking. It allows the operator to precisely align a workpiece on a milling machine and rotate it to different angles. This is especially useful for operations that require circular cuts, complex angle cuts, or intricate designs.

The Importance of a Rotary Table in Milling

Incorporating a rotary table into your milling operations can greatly improve your output by offering unparalleled versatility and precision. It is especially beneficial for tasks such as gear cutting, producing arcs, creating complex shapes, and more.

Setting Up the Rotary Table

Setting up your rotary table is a crucial step. Heres how to do it:

- First, clean the table and remove any debris.

- Position the rotary table securely on the milling machines table using T-slots.

- Use a dial indicator to ensure that the rotary table is perfectly level and centered.

- Tighten all clamps and locks securely.

Basic Operations with a Rotary Table

There are several basic operations you can perform with a rotary table:

- Cutting Circular Profiles: Rotate the table to cut precise circular profiles on your workpiece.

- Creating Bolt Patterns: Use the rotary table to accurately space bolt patterns on a flange.

- Angle Cuts: Tilt the rotary table to perform accurate angle cuts.

Advanced Machining Techniques

Using Dividing Plates

Dividing plates allow you to divide a circle into an equal number of divisions. This is particularly useful for gear cutting. Attach the dividing plates, and you can achieve precise gear teeth formation.

Concentric Machining

Concentric machining is the process of creating concentric circles. This is often used for decorative purposes or for parts that need to be perfectly balanced.

Speed and Feed Rates

Choosing the correct speed and feed rates is essential for achieving the best results:

- Material Type: Different materials require different cutting speeds.

- Tool Type: Use the appropriate cutting tools for your material.

- Machine Capabilities: Ensure your milling machine can handle the required speeds and feeds.

Common Mistakes to Avoid

Avoiding common mistakes can save you time and materials:

- Improper Setup: Always ensure the rotary table is properly set up to avoid inaccurate cuts.

- Wrong Tools: Use the correct tools for your material to prevent damage.

- Incorrect Speed and Feed Rates: Always choose the right speed and feed rates to avoid damaging your workpiece or tools.

Safety Precautions

Safety should always be a priority. Here are some tips:

- Wear appropriate protective gear such as safety glasses and gloves.

- Keep the work area clean to prevent accidents.

- Ensure all clamps and bolts are securely tightened before starting the machine.

Conclusion

Learning how to use a rotary table on a milling machine can significantly improve your machining efficiency and precision. With practice and patience, you’ll be able to perform complex cuts and shapes with ease. For further reading on milling machines, you can visit this resource.

FAQs

What is the purpose of a rotary table on a milling machine?

A rotary table is used to precisely position a workpiece and perform various machining operations, such as cutting circular profiles, creating bolt patterns, and making accurate angle cuts.

How do I set up a rotary table on a milling machine?

Clean the table, position the rotary table securely using T-slots, level it with a dial indicator, and tighten all clamps and locks.

What are some advanced techniques for using a rotary table?

Advanced techniques include using dividing plates for gear cutting and performing concentric machining to create concentric circles.