Using a tachometer on a centrifuge may seem daunting, but it is a crucial process in various industries, especially for Quality Assurance (QA) professionals. With the aid of a tachometer, you can measure the rotational speed of a centrifuge accurately, ensuring that your processes are working optimally.

In this guide, we will delve deep into the process of using a tachometer on a centrifuge, offering a streamlined approach for all industry professionals.

Understanding the Basics

What is a Tachometer?

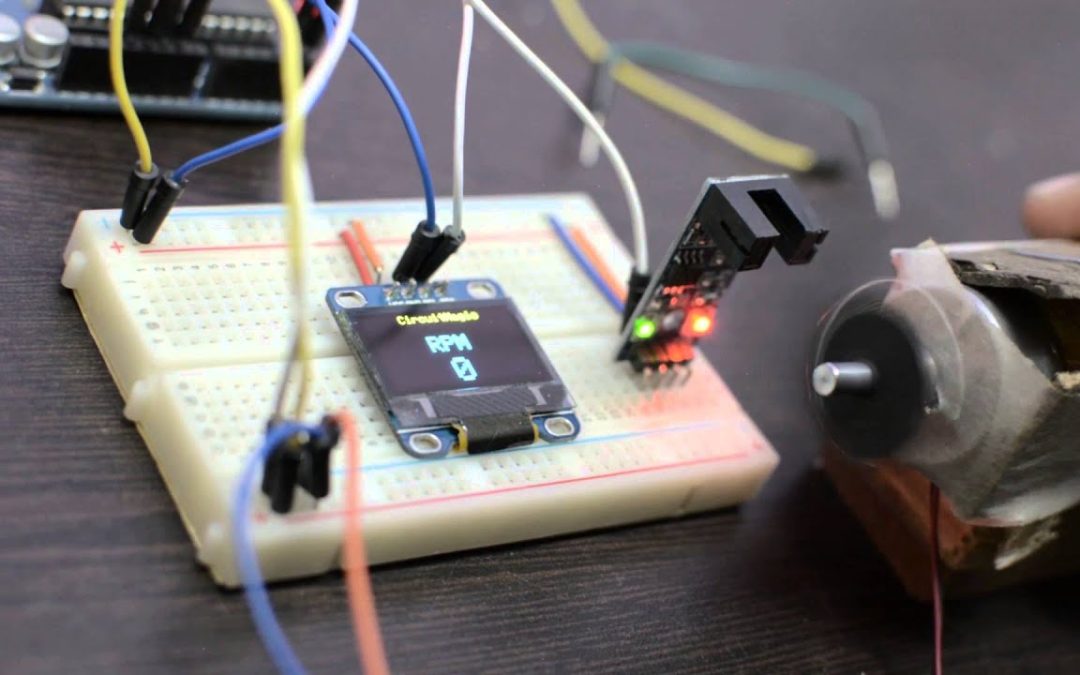

A tachometer is an instrument used to measure the rotation speed of a shaft or disk, as in a motor or other machinery. It can be analog or digital. Digital tachometers are often preferred for their precision and ease of use. [Read more about tachometers](https://megadepot.com/resource/what-is-a-tachometer-and-how-does-it-work?srsltid=AfmBOoqLMgpomcoHAuHxn1twIqRECMqPhueDpLQTjF4nX49c9hnrRu4w) here.

Why is Speed Measurement Important?

In centrifuges, measuring the rotation speed is critical to ensure the consistency and reliability of the process. This measurement helps in maintaining the desired centrifugation conditions, which in turn affects the integrity of the samples.

Equipment Needed

- Digital Tachometer

- Centrifuge

- Adhesive Reflective Tape

- Safety Gear

Setting Up the Tachometer

Step 1: Preparing the Centrifuge

Before attaching the tachometer, ensure that the centrifuge is clean and dry. This prevents any errors in speed reading caused by unwanted debris or moisture.

Step 2: Applying Reflective Tape

Place a small piece of adhesive reflective tape on the rotor or the external surface of the centrifuge. This will serve as a target point for the tachometer’s laser.

Step 3: Powering up the Tachometer

Switch on the digital tachometer and set it to the correct mode if it has multiple settings. Refer to the user manual for specific instructions.

Taking the Measurement

Aligning the Laser Pointer

Aim the laser pointer of the tachometer at the reflective tape. Ensure you are maintaining a stable position to get an accurate reading.

Observing the Reading

Once aligned, the tachometer will display the rotational speed. Make sure to take several readings to ensure accuracy.

Recording the Data

Note down the readings in your lab record for future reference. These records are crucial for tracking the performance of the centrifuge over time.

Common Issues and Troubleshooting

Problem: Inconsistent Readings

Solution: Ensure the reflective tape is clean and properly adhered. Calibrate the tachometer if necessary.

Problem: No Reading Displayed

Solution: Check if the tachometer is switched on and the laser is functioning. Also, ensure you are within the operational range.

Safety Precautions

Personal Safety Gear

Always wear safety goggles and gloves when working with centrifuges and tachometers to protect from any unexpected issues.

Following Manufacturer Guidelines

Adhere to the centrifuge and tachometer manufacturer’s guidelines for the best results and to maintain equipment integrity.

Best Practices for QA Professionals

Regular Calibration

Ensure that the tachometer is regularly calibrated for sustained accuracy.

Consistency in Measurement

Take readings at consistent points in the centrifuge’s operation cycle for reliable data.

Proper Record Keeping

Maintaining thorough records helps in identifying trends and potential issues before they become significant problems.

Benefits of Using a Tachometer on a Centrifuge

- Precision in speed measurement

- Improves overall process efficiency

- Ensures sample integrity

- Aids in troubleshooting mechanical issues

- Enhances data accuracy

Advanced Tips for Professionals

Integrating with Data Systems

Connect your tachometer to digital data collection systems for real-time monitoring and better data management.

Routine Maintenance

Regularly check both the centrifuge and the tachometer for signs of wear and tear to prevent malfunctions.

Training and Development

Invest in training programs for staff to ensure they understand how to use these instruments effectively.

Conclusion

Using a tachometer on a centrifuge is a straightforward yet essential task that ensures optimal performance and sample integrity in various industrial settings. By following the steps in this guide, QA professionals can improve their processes and maintain high standards of quality.

Faq Section

Q: What is the main purpose of a tachometer on a centrifuge?

A: The primary purpose is to measure the rotational speed accurately, ensuring the centrifuge operates optimally.

Q: How often should the tachometer be calibrated?

A: Regular calibration is recommended, ideally every few months, to maintain accuracy.

Q: Can a tachometer be used on other equipment?

A: Yes, tachometers are versatile and can be used on various equipment to measure rotational speed.