How to wire a tachometer to coil is a topic that often perplexes many automotive enthusiasts and industry professionals alike. Whether you are an amateur tinkering with your first project or a seasoned professional, understanding how to correctly wire a tachometer to a coil is essential. Installing a tachometer, an instrument that measures the rotation speed of a shaft or disk in an engine, can be simpler than it seems when broken down into easy-to-follow steps.

Understanding the Basics

The tachometer is a crucial tool for anyone wanting to keep tabs on their engine’s performance. It provides real-time updates on the engine’s revolutions per minute (RPM), allowing for more informed decision-making and engine management.

Why Wire a Tachometer to a Coil?

Wiring a tachometer to a coil provides several advantages. It ensures accurate RPM readings, helps prevent engine damage from over-revving, and improves vehicle performance. Knowing how to wire a tachometer to coil can help save on costly repairs and extend the lifespan of your engine.

Tools You Will Need

- Screwdrivers

- Wire strippers

- Electrical tape

- A tachometer

- Voltage tester

- Wrench set

Preparation Steps

Before starting, always ensure the vehicle is turned off and the keys are removed from the ignition. Safety should be your top priority.

Step-by-Step Guide

1. Locate the Ignition Coil

First, locate your vehicle’s ignition coil. The coil is usually found near the engine and is connected to the distributor cap.

2. Identify the Tachometer Wire

Next, identify the wire on the tachometer that needs to be connected to the ignition coil. This wire is often green.

3. Connect the Wire

Using the wire strippers, strip a small section of insulation from the tachometer wire. Connect it to the negative terminal of the ignition coil.

4. Secure the Connection

Secure the connection using electrical tape or wire connectors. Ensure that it is properly insulated to prevent any electrical shorts.

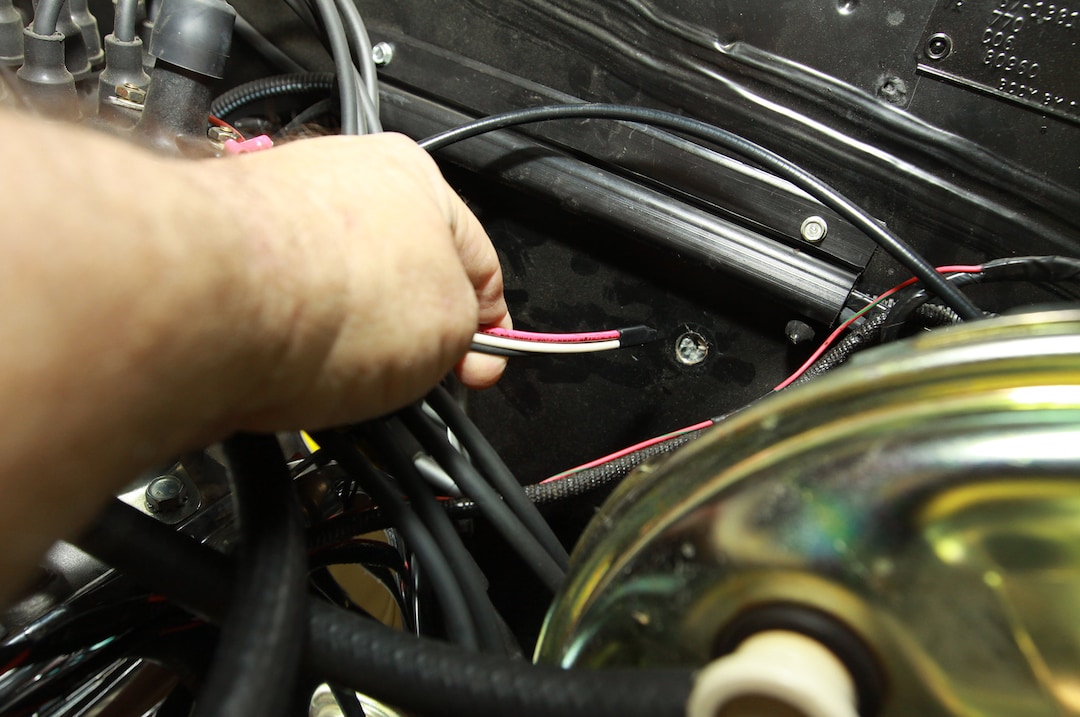

5. Route the Wire

Carefully route the tachometer wire through the engine bay, ensuring it is away from any hot surfaces or moving parts.

Tuning and Calibration

Once the wiring is complete, turn on the vehicle and check the tachometer readings. If necessary, refer to the tachometer’s manual for calibration instructions.

Troubleshooting Common Issues

If the tachometer doesn’t work, double-check the connections. Ensure the wire is connected to the negative terminal of the ignition coil and not the positive.

Maintenance Tips

Regularly check the connections and the wire insulation for wear and tear. Keeping everything in good condition will ensure the longevity and accuracy of the tachometer.

Applications in Industry

Tachometers are not only useful in cars but also in various industrial applications, such as high-speed semiconductor manufacturing inspection and high-speed genetic analysis and sequencing monitoring. These tools help in ensuring machinery operates within safe RPM ranges.

Real-World Examples

In high-speed paint and coating application inspection, tachometers are crucial for maintaining consistent speeds during production. You can read more about such applications here.

Further Reading

For those looking to expand their knowledge on tachometers, consider visiting this resource for a detailed explanation of how tachometers work.

FAQs

1. Can I wire a tachometer to any coil?

Generally, yes. However, it’s best to consult your vehicle’s manual or a professional to ensure compatibility.

2. What happens if the tachometer wire touches a hot surface?

The insulation can melt, causing a short circuit. Always ensure the wire is routed safely.

3. Do all tachometers require calibration?

Most modern tachometers are pre-calibrated, but it’s always good to check the manual.