In the world of quality assurance, choosing between low vs high frequency inspection is a critical decision that can significantly impact the efficiency and effectiveness of an inspection process. This article will delve into the intricacies of both low and high frequency inspections, helping industry QA professionals to make informed decisions.

What is Inspection Frequency?

Before diving into the differences, it is important to understand what inspection frequency entails. Essentially, it refers to the rate at which inspections are conducted over a certain period. For a deeper understanding, you can explore more about frequency in inspection tools.

Defining Low Frequency Inspection

Low frequency inspection involves conducting inspections at longer intervals. This approach is often utilized in scenarios where products have a longer shelf life or where the risk of defects is relatively low.

Defining High Frequency Inspection

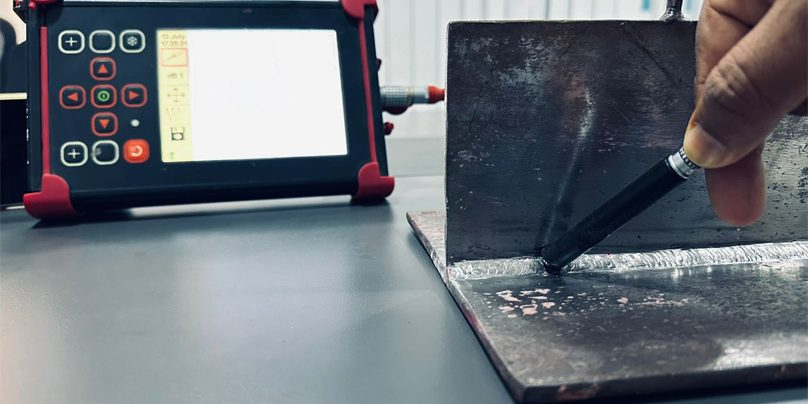

High frequency inspection, on the other hand, involves more frequent checks. This is particularly beneficial in industries where product reliability is crucial, such as in the inspection of wind turbines.

The Importance of Choosing the Right Frequency

Choosing the right inspection frequency is vital for maintaining product quality and cost-effectiveness. A well-chosen frequency ensures that defects are detected early, reducing the risk of product recalls or failures.

Factors Influencing Inspection Frequency

Several factors may influence the decision between low and high frequency inspections. These include the nature of the product, regulatory requirements, and the potential impact of defects.

Product Nature

The nature of the product being inspected plays a significant role. Products that are prone to wear and tear or have a shorter lifespan may require high frequency inspections.

Regulatory Requirements

Regulations in certain industries mandate specific inspection frequencies. It is essential to stay informed about these requirements to ensure compliance.

Impact of Defects

The potential impact of a defect on the end-user is another critical consideration. Products that pose significant safety risks may necessitate more frequent inspections.

Benefits of High Frequency Inspection

Conducting high frequency inspections can lead to early defect detection, improved safety, and enhanced product reliability. For more insights, you can read about the synchronization in automotive inspection tools.

Drawbacks of High Frequency Inspection

Despite its benefits, high frequency inspections can be resource-intensive. They may require significant time and financial investments.

Cost Implications

The cost of frequent inspections can add up quickly, impacting the overall budget of the quality assurance department.

Resource Allocation

More frequent inspections demand more resources, including personnel and equipment, which can strain existing capabilities.

When to Opt for Low Frequency Inspection

Low frequency inspections are suitable when the risk of defects is low, or when the cost of frequent inspections outweighs the benefits. For instance, in industries where the product’s life cycle is extensive, such as optical inspection devices.

Challenges Posed by Low Frequency Inspection

While cost-effective, low frequency inspections may miss gradual deterioration or defects that develop over time.

Risk of Overlooking Defects

With longer intervals between inspections, there is a risk of overlooking emerging defects, which can lead to larger issues down the line.

Delayed Response

A low frequency inspection approach may result in delayed response times to quality issues, potentially affecting customer satisfaction.

Balancing Inspection Frequency

The key to effective inspection lies in balancing between low and high frequency inspections. Understanding the specific needs and characteristics of your industry and products is crucial in making the right choice.

Conclusion

In summary, the choice between low vs high frequency inspection is pivotal in ensuring the quality and reliability of products. By assessing the specific needs of your product and industry, and considering factors like cost, risk, and regulatory requirements, you can determine the most suitable frequency for your inspections. For more insights, check out this external guide on determining inspection frequency.

FAQs

What factors determine inspection frequency?

Inspection frequency is determined by product nature, regulatory requirements, and the potential impact of defects.

What are the benefits of high frequency inspection?

High frequency inspections offer early defect detection, improved safety, and enhanced product reliability.

When should low frequency inspection be used?

Low frequency inspection is ideal when the defect risk is low, or when frequent inspections are not cost-effective.

This article contains affiliate links. We may earn a commission at no extra cost to you.