In the world of industrial quality assurance, the concept of phase synchronization in vibration tools is gaining significant attention. This method is crucial for ensuring the accuracy and efficiency of various processes. By understanding how phase synchronization works, industry QA professionals can enhance the performance of their tools and achieve more precise results.

Phase synchronization involves aligning the phases of different vibration tools to ensure they work in harmony. This synchronization is essential in applications where precise timing and coordination are critical. For example, in ultrasonic testing, proper phase synchronization can significantly improve the accuracy of flaw detection. You can learn more about optimal frequency settings for crack detection, which is closely related to phase synchronization.

The Importance of Phase Synchronization

Phase synchronization is vital in various industrial applications. It ensures that all tools and devices operate in unison, leading to more accurate measurements and enhanced performance. Without proper synchronization, there can be discrepancies in data, leading to potential errors and inefficiencies.

In the context of vibration tools, phase synchronization helps in reducing noise and improving signal clarity. This is especially important in environments where precise measurements are required, such as in quality assurance and testing laboratories. A detailed look into inspection accuracy can provide more insights.

Techniques for Achieving Phase Synchronization

Using Advanced Technology

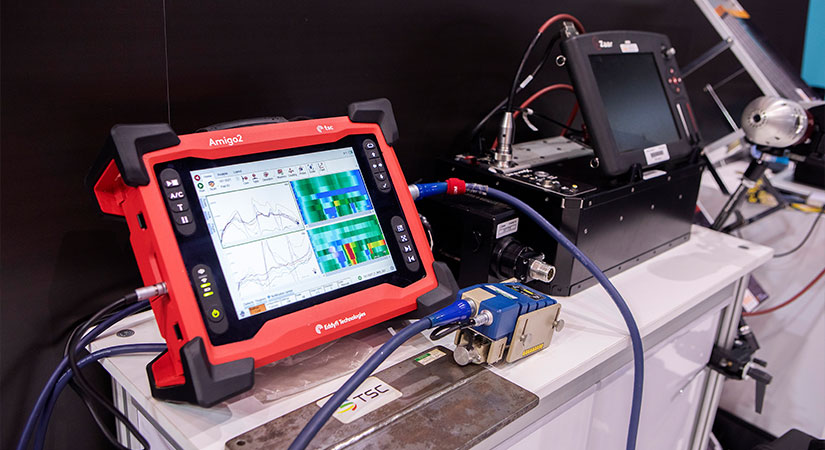

Modern vibration tools are equipped with advanced technology that facilitates phase synchronization. These tools often come with built-in synchronization features that automatically align the phases of different devices to improve coordination and accuracy.

Manual Synchronization Methods

For tools that do not have automatic synchronization features, manual methods can be employed. This involves adjusting the settings of each tool to ensure they are in sync. While this method requires more effort, it is essential for tools that do not support automatic synchronization.

Calibration and Adjustment

Regular calibration and adjustment are crucial for maintaining synchronization. This involves checking the settings and performance of each tool regularly to ensure they are operating correctly. For more detailed information on calibration, visit frequency calibration in ultrasonic devices.

Benefits of Proper Phase Synchronization

Achieving proper phase synchronization in vibration tools offers several benefits:

- Increased accuracy and precision in measurements

- Reduced noise and interference

- Improved efficiency and performance of tools

- Enhanced reliability of data collected

Challenges in Implementing Phase Synchronization

Despite its benefits, implementing phase synchronization can be challenging. Some of the common challenges include:

- Compatibility issues between different tools and devices

- Complexity in settings and adjustments

- Need for regular maintenance and calibration

Addressing these challenges requires a comprehensive understanding of the tools and their synchronization capabilities. Resources such as synchronization between sensors can provide further guidance.

Applications of Phase Synchronization in Industry

Phase synchronization is widely used in various industries, including:

- Aerospace: For precise measurements in aircraft manufacturing and maintenance.

- Automotive: To enhance the accuracy of diagnostic tools and testing equipment.

- Manufacturing: For quality control and assurance in production lines.

Future Trends in Phase Synchronization

As technology continues to advance, the future of phase synchronization looks promising. Emerging trends include:

- Integration of artificial intelligence for automatic synchronization

- Development of more sophisticated synchronization tools

- Increased adoption of cloud-based synchronization systems

Conclusion

In conclusion, phase synchronization in vibration tools is a critical aspect of industrial quality assurance. It ensures precision, accuracy, and efficiency in various applications, making it an essential practice for industry QA professionals. By understanding and implementing proper synchronization techniques, professionals can enhance the performance of their tools and achieve better results in their operations.

FAQs

What is phase synchronization in vibration tools?

Phase synchronization in vibration tools involves aligning the phases of different tools to ensure they work in harmony, improving accuracy and efficiency.

Why is phase synchronization important?

It is important because it reduces noise, improves signal clarity, and enhances the accuracy and performance of various industrial processes.

How can phase synchronization be achieved?

It can be achieved using advanced technology, manual synchronization methods, and regular calibration and adjustment of tools.

For further reading on related topics, you can visit how often should stamping tools be inspected.

This article contains affiliate links. We may earn a commission at no extra cost to you.