In today’s fast-paced motorcycle manufacturing industry, the need to maintain high-quality standards while reducing costs is paramount. One of the significant challenges faced by manufacturers is paint rework. Paint defects not only increase production costs but also delay delivery times and reduce customer satisfaction. Fortunately, with the advent of AI-driven solutions, the industry is witnessing a tremendous shift in how these issues are addressed.

This article delves into the world of AI technology and its profound impact on reducing motorcycle paint rework. We’ll walk you through the intricacies of how AI is revolutionizing the motorcycle industry, ensuring a higher quality finish, and providing solutions that are both efficient and cost-effective.

What Causes Paint Rework in Motorcycle Manufacturing?

Before diving into the solutions, it’s essential to understand the primary causes of paint rework in motorcycle manufacturing:

Poor Surface Preparation

One of the most common causes of paint defects is inadequate surface preparation. Dust, dirt, and oil residues can lead to poor paint adhesion, resulting in a subpar finish.

Environmental Factors

Environmental conditions such as temperature, humidity, and contamination can significantly impact the paint application process, leading to defects like blisters, bubbles, and uneven finishes.

Application Errors

Mistakes during the paint application process, such as incorrect spray gun settings, can lead to an uneven coat, runs, and sags.

Material Quality

The quality of the paint material itself can also play a crucial role. Inferior paint materials can result in fading, chipping, and other defects over time.

How AI-Driven Solutions Are Transforming the Industry

The integration of AI in motorcycle manufacturing is creating a paradigm shift. Here’s how AI-driven solutions are tackling the issue of paint rework:

Automated Surface Inspection

AI-powered cameras and sensors can detect even the slightest imperfections on the motorcycle’s surface before the paint is applied. This ensures that any defects are addressed promptly, reducing the chances of rework.

Precision Environmental Control

Advanced AI systems can monitor and control environmental conditions within the painting booth. By maintaining optimal temperature and humidity levels, these systems help ensure a consistent and high-quality paint finish.

Real-Time Application Monitoring

AI-driven tools can monitor the paint application process in real-time, adjusting spray gun settings and application techniques to achieve a flawless finish. This reduces the likelihood of defects caused by human error.

Advanced Material Selection

AI algorithms can analyze and recommend the best paint materials based on various factors such as surface type, environmental conditions, and desired finish. This ensures that the right materials are used for each specific application.

Case Studies: Success Stories of AI Integration

Let’s take a look at some real-world examples of how AI-driven solutions are reducing paint rework in the motorcycle industry:

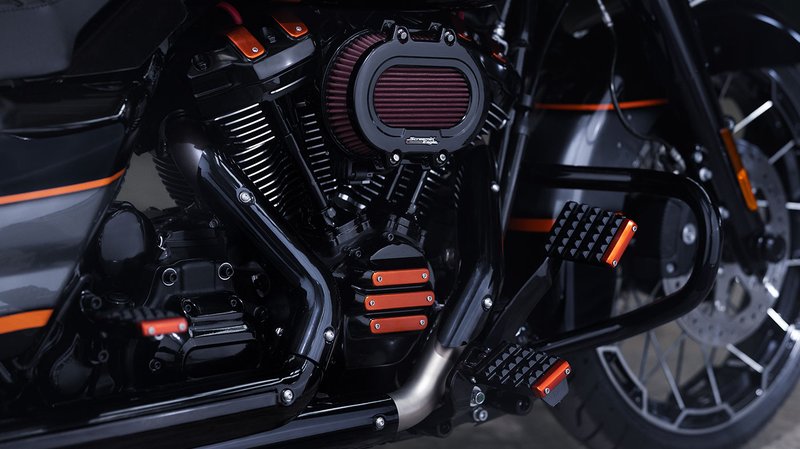

Case Study 1: Harley-Davidson’s AI-Powered Paint Shop

Harley-Davidson has implemented AI-driven solutions in their paint shop to enhance the quality of their finishes. By integrating AI-powered surface inspection and application monitoring systems, they have significantly reduced paint rework and improved overall customer satisfaction. For more information, you can visit their official announcement here.

Case Study 2: Custom Motorcycle Manufacturer

A custom motorcycle manufacturer utilized AI algorithms to select the best paint materials for their unique designs. This approach has led to a noticeable improvement in the durability and appearance of their custom paint jobs.

The Economic Impact of AI-Driven Solutions

The implementation of AI-driven solutions brings numerous economic benefits to the motorcycle manufacturing industry:

Cost Reduction

Reducing paint rework directly translates to lower production costs. By minimizing defects, manufacturers can save on materials, labor, and time.

Increased Efficiency

AI systems streamline the painting process, reducing the need for manual intervention and allowing for faster production cycles.

Enhanced Quality Control

With AI’s precision and real-time monitoring, manufacturers can achieve higher quality finishes, reducing the likelihood of customer returns and warranty claims.

Competitive Advantage

Manufacturers that adopt AI-driven solutions gain a competitive edge by delivering superior quality products and meeting customer expectations consistently.

Challenges and Considerations in Implementing AI Solutions

While the benefits of AI-driven solutions are undeniable, there are several challenges and considerations that manufacturers should keep in mind:

Initial Investment

The implementation of AI systems requires a significant upfront investment. However, the long-term benefits and cost savings often justify the initial costs.

Data Quality

AI systems rely heavily on data. Ensuring the accuracy and reliability of data inputs is crucial for achieving optimal results.

Staff Training

Manufacturers need to invest in training their staff to work with AI systems effectively. This includes understanding how to interpret AI-generated data and make informed decisions based on it.

Integration with Existing Systems

Integrating AI solutions with existing manufacturing processes can be complex. Manufacturers must carefully plan and execute the integration to avoid disruptions.

Future Trends in AI-Powered Paint Shops

The future of AI-driven solutions in motorcycle paint shops looks promising. Here are some trends to watch for:

Enhanced Predictive Maintenance

AI systems will evolve to predict and address maintenance issues before they occur, reducing downtime and improving overall efficiency.

Advanced Robotics

Integration of AI with advanced robotics will further automate the painting process, increasing precision and speed.

Sustainable Practices

AI-driven solutions will increasingly focus on sustainability, optimizing paint usage and minimizing waste to reduce the environmental impact.

Customization and Personalization

AI algorithms will enable highly personalized and customized paint designs, catering to individual customer preferences and trends.

Conclusion

The incorporation of AI-driven solutions into motorcycle paint shops is revolutionizing the industry. By addressing the root causes of paint rework, enhancing quality control, and providing economic benefits, AI is proving to be an invaluable asset for manufacturers. As technology continues to advance, the potential for AI to further transform the motorcycle industry is limitless.

For more insights on how AI is driving innovation across various industries, you can read about AI-Driven Genetic Analysis or explore our article on Semiconductor Manufacturing Inspection.

Frequently Asked Questions (FAQs)

What is the main cause of paint defects in motorcycle manufacturing?

The primary causes include poor surface preparation, environmental factors, application errors, and material quality.

How do AI-driven solutions reduce paint rework?

AI-driven solutions improve surface inspection, control environmental conditions, monitor application processes, and recommend the best materials, thereby reducing defects and the need for rework.

What are the economic benefits of implementing AI in motorcycle paint shops?

Economic benefits include cost reduction, increased efficiency, enhanced quality control, and gaining a competitive advantage.