In the realm of industrial quality assurance, ensuring the utmost precision and efficiency is paramount. This is especially true when it comes to synchronization software for imaging inspections. As industries continue to advance technologically, the demand for accurate and efficient inspection processes has grown exponentially. At the forefront of this evolution is the use of synchronization software, which plays a pivotal role in enhancing the accuracy of imaging inspections.

What is Synchronization Software?

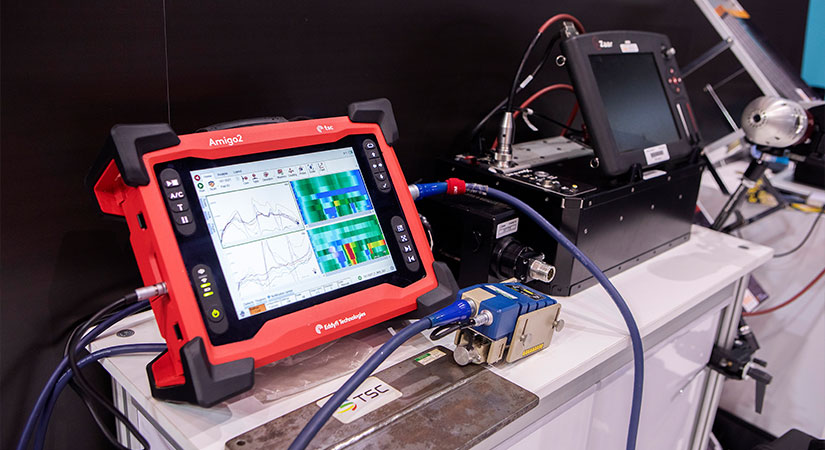

Synchronization software refers to the technology that ensures all imaging devices and systems work in harmony. In the context of imaging inspections, this means that cameras, sensors, and other imaging tools are coordinated to capture data simultaneously and accurately. This coordination is crucial in industries where precision is non-negotiable.

Importance of Imaging Inspections in Industry

Imaging inspections are integral to maintaining quality and safety standards across various industries. Whether it’s in manufacturing, construction, or aerospace, the ability to detect flaws and inconsistencies in materials and structures can prevent costly errors and enhance product quality. Effective imaging inspections rely heavily on the synchronized operation of imaging tools.

Enhancing Accuracy with Synchronization

The primary benefit of using synchronization software in imaging inspections is the substantial increase in accuracy. When imaging devices are synchronized, the likelihood of errors caused by timing discrepancies is significantly reduced. This means that inspections can be conducted with a higher degree of precision, leading to better quality outcomes.

Efficiency Gains in Inspection Processes

Beyond accuracy, synchronization software also enhances the efficiency of inspection processes. By ensuring that all imaging tools operate in unison, the overall inspection time can be reduced. This not only speeds up the production process but also allows for more frequent inspections, leading to continual quality improvements.

Applications in Various Industries

The applications of synchronization software in imaging inspections are vast and varied. In the automotive industry, for instance, synchronized imaging ensures that every component of a vehicle is inspected thoroughly. In aerospace, precision is critical, and synchronized inspections can detect even the smallest defects in aircraft components.

Automotive Industry

In the automotive sector, synchronization software is used to ensure that components such as engines and chassis are free from defects. This is crucial in maintaining the safety and reliability of vehicles on the road.

Aerospace Sector

For the aerospace industry, where the margin for error is minuscule, synchronized imaging inspections can prevent catastrophic failures by identifying potential issues before they become serious problems.

The Role of Technology in Advancing Synchronization

Technology has been a driving force behind the advancements in synchronization software. With the advent of AI and machine learning, synchronization software has become more sophisticated, offering unprecedented levels of precision and efficiency.

AI and Machine Learning

AI and machine learning algorithms can analyze vast amounts of data quickly and accurately, making them invaluable tools in synchronization software. These technologies can predict potential issues and optimize inspection processes, further enhancing the efficacy of imaging inspections.

Challenges and Solutions in Implementing Synchronization Software

While the benefits of synchronization software are clear, implementing this technology is not without its challenges. These can include integration with existing systems and the need for specialized training for personnel.

Integration Challenges

Integrating synchronization software with existing systems can be a complex process. However, advances in technology have led to the development of more adaptable synchronization solutions that can be seamlessly integrated into existing infrastructures.

Training and Skill Development

To maximize the benefits of synchronization software, industries must invest in training their workforce. This includes not only understanding how to use the software but also interpreting the data it provides to make informed decisions.

Future Trends in Synchronization Software

Looking forward, the future of synchronization software in imaging inspections is bright. As technology continues to evolve, so too will the capabilities of synchronization software, leading to even greater precision and efficiency in inspection processes.

Emerging Technologies

Emerging technologies such as the Internet of Things (IoT) and blockchain are set to play significant roles in the future of synchronization software. These technologies can provide new ways to enhance the reliability and security of synchronization processes.

Continual Innovation

As industries strive for greater efficiency and quality, continual innovation in synchronization software will be essential. This will involve the development of new features and functionalities that address the evolving needs of various industries.

Conclusion

Synchronization software is revolutionizing how industries conduct imaging inspections. By enhancing accuracy and efficiency, this technology is setting new standards for quality assurance across various sectors. As technological advancements continue to shape the future of synchronization software, its impact on imaging inspections will only grow stronger.

FAQs

What is synchronization software used for?

Synchronization software is used to coordinate the operation of imaging devices and systems to ensure accurate and efficient data capture during inspections.

How does synchronization software improve inspection accuracy?

By ensuring that all imaging tools operate in harmony, synchronization software minimizes timing discrepancies, thus enhancing the precision of inspections.

What industries benefit from synchronization software?

Industries such as automotive, aerospace, and manufacturing benefit significantly from synchronization software due to their need for precise and efficient inspection processes.

For more information on synchronization in industrial applications, you can visit this external resource or explore the calibration tests role in synchronization.

This article contains affiliate links. We may earn a commission at no extra cost to you.