In the world of engineering, understanding ultrasonic frequency basics is crucial for professionals, especially those in the quality assurance field. These frequencies play a significant role in various applications, ranging from industrial inspections to non-destructive testing methods. By exploring these basics, one can gain insights into how these frequencies are applied and their benefits in modern engineering practices.

What is Ultrasonic Frequency?

Ultrasonic frequency refers to sound waves that have a frequency higher than the upper audible limit of human hearing. While humans can hear up to 20 kHz, ultrasonic frequencies are typically above this range, often starting at 20 kHz and extending into the megahertz (MHz) range. These high-frequency sound waves are utilized in numerous technological and industrial applications.

Applications in Industry

Ultrasonic frequencies are employed in a variety of industries for inspection, cleaning, and testing purposes. In the manufacturing sector, they are used for control loop optimization and anomaly detection in HVAC systems. The ability to detect flaws and inconsistencies without causing damage to the material makes ultrasonic testing an invaluable tool for quality assurance professionals.

Non-Destructive Testing (NDT)

Ultrasonic testing is a form of non-destructive testing (NDT) that uses high-frequency sound waves to detect imperfections in materials. This method allows inspectors to identify cracks, voids, or other anomalies within a component without causing any harm. As a result, ultrasonic testing is widely used in the aerospace, automotive, and construction industries.

Cleaning Applications

In addition to testing, ultrasonic frequencies are also used for cleaning delicate items. The precision of ultrasonic cleaning allows it to remove contaminants from intricate components, such as electronic parts and jewelry. This technique is highly effective and ensures thorough cleaning without physical contact.

How Does Ultrasonic Testing Work?

During ultrasonic testing, a transducer generates high-frequency sound waves that penetrate the material being examined. By analyzing the reflected waves, technicians can identify internal flaws or inconsistencies. This process is highly accurate and can be tailored to suit different materials and inspection requirements.

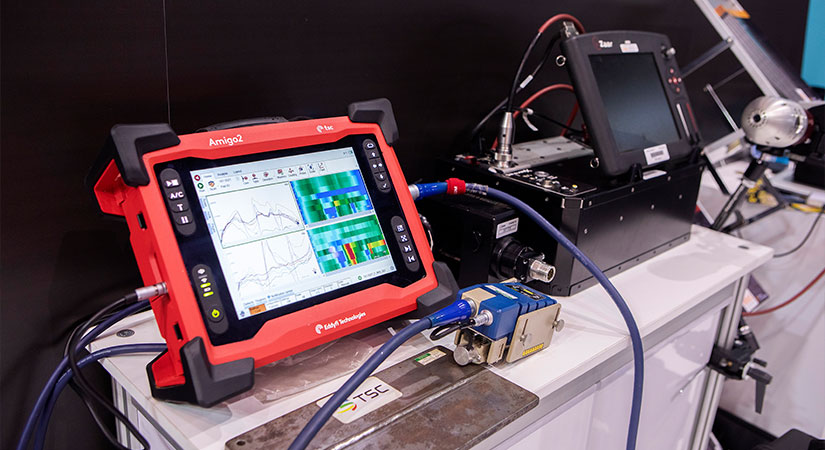

Equipment Used

The equipment used in ultrasonic testing includes a transducer, pulser/receiver, and a display device. The transducer emits the sound waves, while the pulser/receiver generates the electrical impulses. The display device presents the results, allowing inspectors to assess the condition of the material.

Advantages of Ultrasonic Testing

One of the key benefits of ultrasonic testing is its ability to provide precise measurements of material thickness and detect flaws without causing any damage. This makes it an ideal choice for industries where material integrity is crucial. Additionally, this method offers rapid results, enabling efficient quality control processes.

Limitations

Despite its advantages, ultrasonic testing has some limitations. For example, it requires highly skilled technicians to interpret the results accurately. Additionally, surface conditions and the geometry of the test object can affect the accuracy of the readings. Nonetheless, with proper training and equipment, these challenges can be mitigated.

Importance of Ultrasonic Frequencies in Modern Engineering

Ultrasonic frequencies have revolutionized the field of engineering by providing non-invasive methods for inspection and testing. Their ability to detect defects and ensure the integrity of materials enhances safety and reliability across various industries. Furthermore, advancements in technology continue to expand the applications of ultrasonic frequencies, making them indispensable in modern engineering practices.

Future Prospects

As technology evolves, the potential for ultrasonic applications in engineering continues to grow. Innovations in transducer design and data processing are expected to enhance the accuracy and efficiency of ultrasonic testing methods. This will further solidify the role of ultrasonic frequencies in quality assurance and other engineering practices.

External Resources

For more information on the inspection of equipment, visit this guide.

FAQs

What is the range of ultrasonic frequencies?

Ultrasonic frequencies typically start at 20 kHz and can extend into the megahertz range, making them suitable for various industrial applications.

Can ultrasonic testing detect all types of flaws?

While ultrasonic testing is highly effective, it may not detect every type of flaw. Factors such as material properties and surface conditions can influence its accuracy.

How does ultrasonic cleaning work?

Ultrasonic cleaning uses high-frequency sound waves to create microscopic bubbles that remove contaminants from surfaces without physical contact.

This article contains affiliate links. We may earn a commission at no extra cost to you.