Enhancing Vending Machine Maintenance with VendX

Lorem Ipsum is simply dummy text of the typesetting industry.

Vending machines are critical assets in various industries, providing convenient access to a range of products. Ensuring their optimal performance and minimizing downtime are essential for maintaining customer satisfaction and profitability. VendX, an advanced automatic stroboscope, offers a revolutionary solution for monitoring, checking, and predicting health issues in vending machines. This white paper explores the integration of VendX into predictive maintenance strategies for vending machines.

Challenges in Traditional Maintenance

01

Reactive Maintenance

Often, vending machine maintenance is reactive, addressing issues only after they arise. This leads to unexpected downtime and revenue loss.

02

Manual Inspections

Routine manual inspections are time-consuming and may miss subtle signs of wear and tear.

03

Data Deficiency

Lack of real-time data makes it difficult to predict failures and optimize maintenance schedules.

Benefits of Predictive Maintenance

Reduced Downtime

Predictive maintenance minimizes unexpected breakdowns by identifying issues before they escalate.

Cost Efficiency

Early detection of potential problems reduces repair costs and extends the lifespan of vending machines.

Enhanced Reliability

Consistent monitoring ensures machines operate at peak efficiency, improving customer satisfaction.

Introducing VendX:

The Advanced Solution

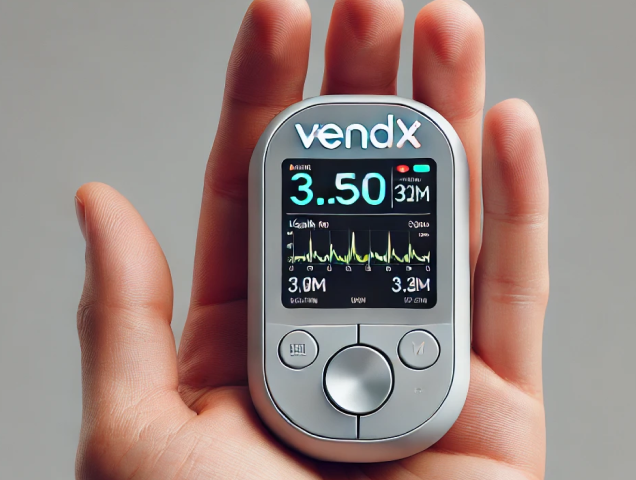

What is VendX?

VendX is an innovative automatic stroboscope designed to monitor and analyze the health of vending machines. It leverages real-time data to predict maintenance needs and prevent unexpected failures.

Key Features

01

Real-Time Vibration Analysis

VendX continuously monitors vibration patterns to detect anomalies.

02

Stroboscopic Event Detection

Identifies and records specific events that indicate potential mechanical issues.

03

Integration with IoT Platforms

VendX can seamlessly connect to leading IoT and predictive maintenance platforms for comprehensive data analysis and reporting.

Installation and Integration

VendX is installed in strategic locations within the vending machine, such as near motors, dispensers, and cooling systems. It connects to an IoT platform, enabling real-time data transmission and analysis.

Data Collection and Analysis

VendX collects vibration data continuously, using its stroboscopic capabilities to detect deviations from normal patterns.

Event Detection:

The system identifies specific stroboscopic events that correlate with mechanical issues, such as motor misalignment or dispenser blockages.

Predictive Analytics:

The collected data is analyzed using advanced algorithms to predict potential failures and maintenance needs.

Benefits Realized

VendX detects issues like motor vibrations and dispenser blockages before they lead to machine failure.

Optimized Maintenance Scheduling:

Maintenance is scheduled based on real-time data and predictive insights, reducing unnecessary maintenance activities.

Increased Machine Uptime:

By preventing unexpected breakdowns, VendX ensures that vending machines are always operational, enhancing customer satisfaction and revenue.

Integration with

Leading IoT Platforms

Siemens MindSphere

VendX integrates with MindSphere to provide detailed analytics and insights into vending machine health. Real-time data visualization and AI-driven insights enhance predictive maintenance strategies.

GE Predix

Integration with GE Predix enables comprehensive monitoring and diagnostics, leveraging Predix’s robust analytics tools for optimized maintenance scheduling and reduced downtime.

IBM Maximo

VendX connects with IBM Maximo to enhance asset health monitoring, providing real-time data collection and reporting to support AI-driven predictive maintenance.

Conclusion

VendX represents a significant advancement in the field of predictive maintenance for vending machines. By leveraging real-time vibration analysis and stroboscopic event detection, VendX provides early fault detection, optimized maintenance scheduling, and increased machine uptime. Integrating VendX with leading IoT platforms ensures comprehensive data analysis and actionable insights, driving efficiency and profitability in vending machine operations.

Appendix

Technical Specifications

Sensor Type:

Advanced automatic stroboscope

Data Transmission:

IoT-enabled, real-time

Integration:

Compatible with major IoT platforms (MindSphere, Predix, Maximo)

Case Study Highlights

30% reduction in unexpected vending machine failures.

Cost Savings:

20% reduction in maintenance costs through optimized scheduling.

Customer Satisfaction:

Improved reliability and uptime, leading to higher customer satisfaction.

Further Reading

Explore the benefits and applications of IoT in predictive maintenance.

Stroboscopic Technology:

Understanding the role of stroboscopes in modern maintenance strategies.

Case Studies:

Real-world examples of VendX in action across various industries.

GET IN TOUCH

This white paper provides a comprehensive overview of how VendX can revolutionize predictive maintenance for vending machines, highlighting its features, benefits, and integration capabilities.