Use Cases and Applications

High-Speed Label Printing Inspection

StroboX utilizes AI and stroboscopic technology to automate the inspection of high-speed label printing presses. It synchronizes with the printing speed to capture clear images and detect defects in real-time.

High-Speed Pharmaceutical Blister Pack Inspection

StroboX utilizes AI and stroboscopic technology to automate the inspection of pharmaceutical blister packs. It synchronizes with production speeds to capture clear images and detect defects in real-time.

High-Speed CNC Machining Inspection

StroboX employs AI and stroboscopic technology to automate the inspection of CNC-machined parts. It synchronizes with the machining speed to capture clear images and detect defects in real-time.

High-Speed Packaging Line Inspection

StroboX utilizes AI and stroboscopic technology to automate the inspection of high-speed packaging lines. It synchronizes with the line speed to capture clear images and detect defects in real-time.

High-Speed Turbine Blade Inspection

StroboX utilizes AI and stroboscopic technology to automate the inspection of turbine blades. It synchronizes with the rotation speed to capture clear images and detect defects in real-time.

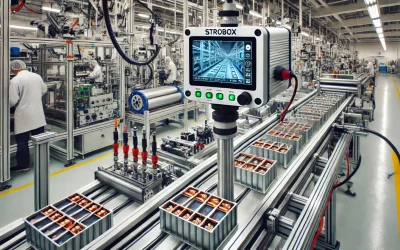

High-Speed Battery Manufacturing Inspection

StroboX employs AI and stroboscopic technology to automate the inspection of battery production lines. It synchronizes with production speeds to capture clear images and detect defects in real-time.

High-Speed Rotating Equipment Inspection in HVAC Systems

StroboX employs AI and stroboscopic technology to automate the inspection of rotating equipment in HVAC systems. It synchronizes with the rotation speed to capture clear images and detect defects in real-time.

Fan Blade Manufacturing Inspection

StroboX utilizes AI and stroboscopic technology to automate the inspection of fan blades during production and testing. It synchronizes with the rotation speed to capture clear images and detect defects in real-time.

High-Speed Semiconductor Wafer Polishing Inspection

StroboX employs AI and stroboscopic technology to automate the inspection of high-speed textile fabric production lines. It synchronizes with production speeds to capture clear images and detect defects in real-time.