In the rapidly evolving world of manufacturing and production, ensuring the highest quality of products is paramount. Visual inspection enhancement plays a crucial role in this process, acting as the frontline defense in quality assurance. As industry professionals, understanding how to effectively implement and improve visual inspection processes can significantly impact product quality and operational efficiency.

With advancements in technology, the traditional methods of visual inspection are being augmented and sometimes replaced by more sophisticated systems. These advancements not only increase accuracy but also speed up the inspection process, ensuring that defects are caught earlier and with greater precision.

Understanding Visual Inspection Enhancement

The term visual inspection enhancement refers to the application of advanced technologies to improve the accuracy and efficiency of visual inspections. This can involve the use of cameras, sensors, and software algorithms to detect defects that might be missed by the human eye. The goal is to ensure that every product meets the required standards before it reaches the consumer.

Importance of Visual Inspection

Visual inspection is a critical component in quality assurance. It helps identify defects, ensure compliance with standards, and maintain brand reputation. By enhancing visual inspection processes, companies can reduce waste, improve efficiency, and increase customer satisfaction.

Technological Advancements

Recent advancements in technology have revolutionized visual inspection processes. From high-resolution cameras to artificial intelligence and machine learning algorithms, these technologies are making inspections faster and more accurate. They enable the detection of minute defects and inconsistencies that would otherwise go unnoticed.

Key Technologies in Visual Inspection Enhancement

High-Resolution Cameras

High-resolution cameras are at the heart of modern visual inspection systems. They provide detailed images that can be analyzed to detect even the smallest defects. These cameras can be integrated with software that automatically identifies and categorizes defects.

Artificial Intelligence and Machine Learning

AI and machine learning are increasingly being used to enhance visual inspection processes. These technologies can learn from past inspections, improving their ability to detect defects over time. They can also analyze large volumes of data quickly, providing insights that can help improve production processes.

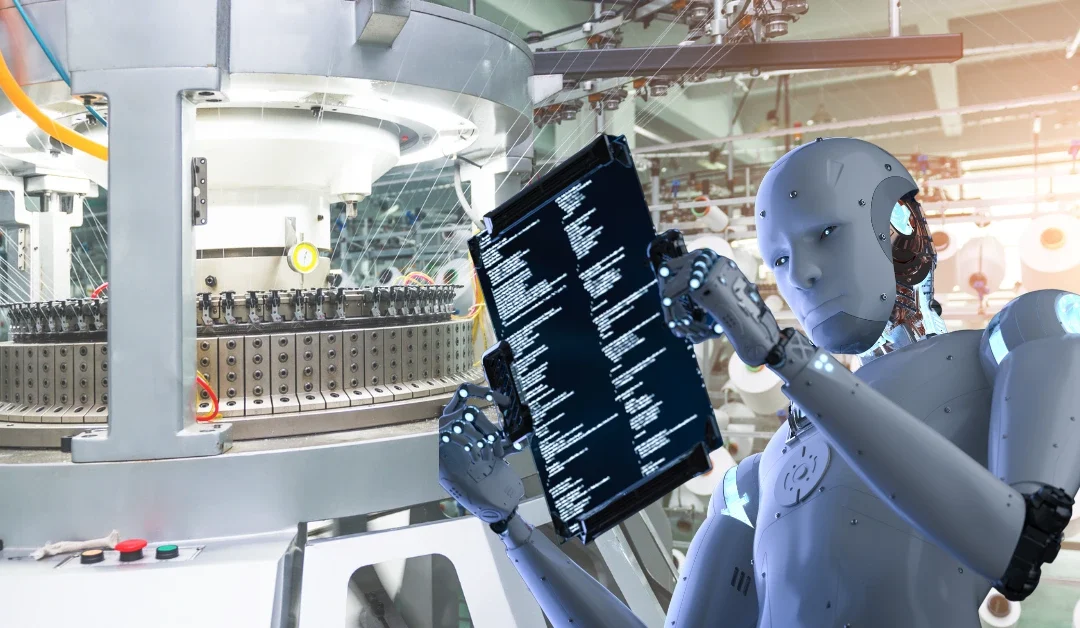

Automation and Robotics

Automation and robotics are playing a significant role in enhancing visual inspections. Automated systems can perform inspections around the clock, without the need for breaks. This increases productivity and ensures that inspections are consistent and reliable.

Benefits of Implementing Visual Inspection Enhancement

Increased Accuracy

Enhanced visual inspection systems are more accurate than traditional methods. They can detect defects that might be missed by the human eye, reducing the risk of defective products reaching the consumer.

Improved Efficiency

By automating the inspection process, companies can significantly increase their efficiency. Automated systems can perform inspections faster and more consistently than human inspectors, reducing the time it takes to identify and address defects.

Cost Savings

While the initial investment in enhanced visual inspection systems can be significant, the long-term cost savings are substantial. By reducing waste and improving efficiency, companies can save money and increase profitability.

Challenges in Implementing Visual Inspection Enhancement

High Initial Costs

The initial cost of implementing advanced visual inspection systems can be high. Companies need to invest in high-resolution cameras, software, and other technologies. However, the long-term benefits often outweigh these initial costs.

Technical Expertise

Implementing and maintaining advanced visual inspection systems requires technical expertise. Companies need to have skilled personnel who can operate and maintain these systems to ensure they function effectively.

Integration with Existing Systems

Integrating new visual inspection technologies with existing production systems can be challenging. Companies need to ensure that new systems are compatible with their existing infrastructure to maximize their benefits.

Future of Visual Inspection Enhancement

Emerging Technologies

The future of visual inspection enhancement looks promising, with several emerging technologies set to revolutionize the industry. Technologies like augmented reality and the Internet of Things (IoT) are expected to play a significant role in the future of visual inspections.

Continued Advancements in AI

AI and machine learning are expected to continue advancing, providing even more accurate and efficient visual inspection processes. These technologies will enable companies to detect defects earlier and with greater precision.

Increased Adoption

As the benefits of enhanced visual inspection systems become more apparent, more companies are expected to adopt these technologies. This will lead to increased competition and innovation in the industry, driving further advancements.

Conclusion

In conclusion, visual inspection enhancement is a critical component of modern quality assurance processes. By leveraging advanced technologies, companies can improve the accuracy and efficiency of their inspections, reducing waste and increasing customer satisfaction. While there are challenges to implementing these systems, the long-term benefits make it a worthwhile investment for any company looking to improve their quality assurance processes.

FAQ

What is visual inspection enhancement?

Visual inspection enhancement refers to the use of advanced technologies to improve the accuracy and efficiency of visual inspections in quality assurance processes.

Why is visual inspection important?

Visual inspection is important because it helps identify defects, ensure compliance with standards, and maintain brand reputation. Enhanced visual inspections can significantly improve these processes.

What are the benefits of visual inspection enhancement?

Benefits include increased accuracy, improved efficiency, and cost savings. These systems can detect defects earlier and with greater precision, reducing waste and improving profitability.

For more information on stroboscope lights and their importance, you can visit Raptor Supplies blog.

Additionally, to learn more about energy-efficient stroboscopic systems, check out Strobox AI.

This article contains affiliate links. We may earn a commission at no extra cost to you.