Multi-axis milling machines have revolutionized the manufacturing industry. The sophisticated capabilities of these machines have enabled precise, efficient, and versatile production processes. Industry QA Professionals are particularly delighted with the outlook this technology offers. In this article, we delve into the tremendous benefits of using multi-axis milling machines and why they are the future of manufacturing.

1. Introduction to Multi-axis Milling Machines

Before diving into the advantages of multi-axis milling machines, it is essential to understand what these machines are and how they function. Unlike traditional milling machines that operate on three axesX, Y, and Zmulti-axis machines add extra axes. This often includes a rotary axis and another axis for improved maneuverability and operational flexibility.

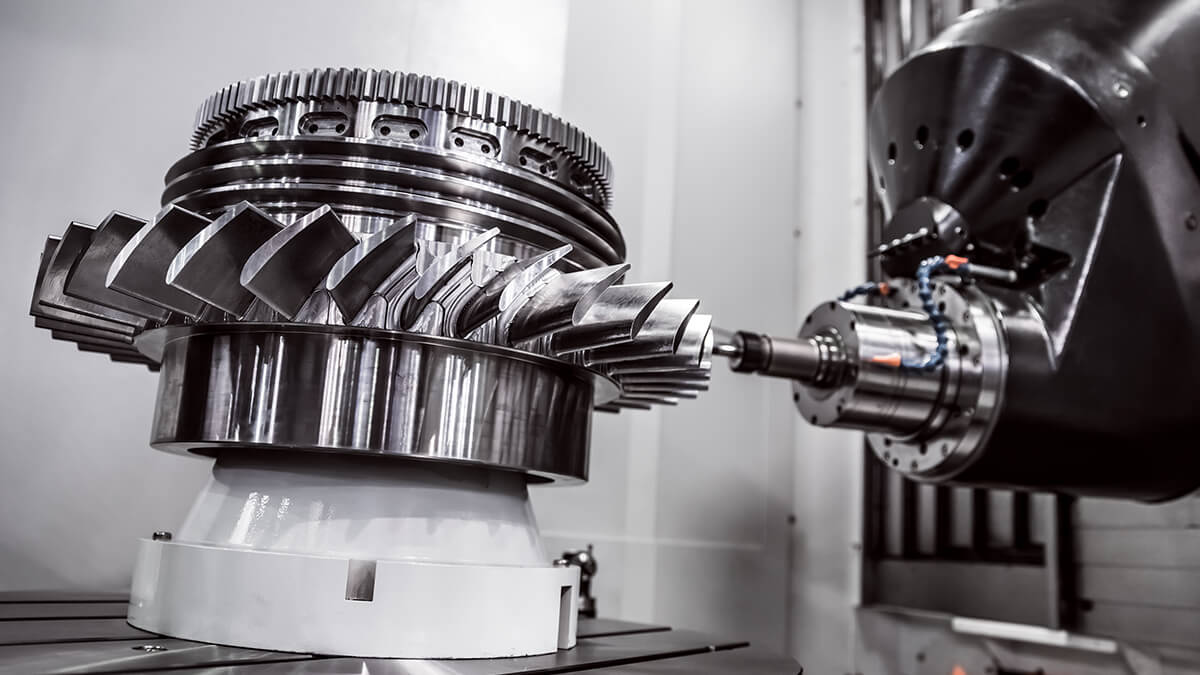

2. Tremendous Precision and Accuracy

One of the significant benefits of using multi-axis milling machines is their precision and accuracy. These machines allow for intricate and complex production processes, ensuring that even the minutest details are achieved with high accuracy.

3. Improved Efficiency and Productivity

These machines can perform multiple operations in a single setup, drastically reducing the time and effort required to complete a project. This enhanced efficiency means higher productivity and shorter lead times, which can significantly benefit manufacturing technology.

4. Versatility in Operations

Multi-axis milling machines are incredibly versatile, capable of handling various materials and production tasks. This flexibility is invaluable in an industry that often requires quick adaptations and custom solutions.

5. Cost-Effectiveness

Though the initial investment may seem high, the long-term benefits make multi-axis milling machines a cost-effective solution. The reduction in labor and material waste, combined with higher productivity, leads to substantial cost savings over time.

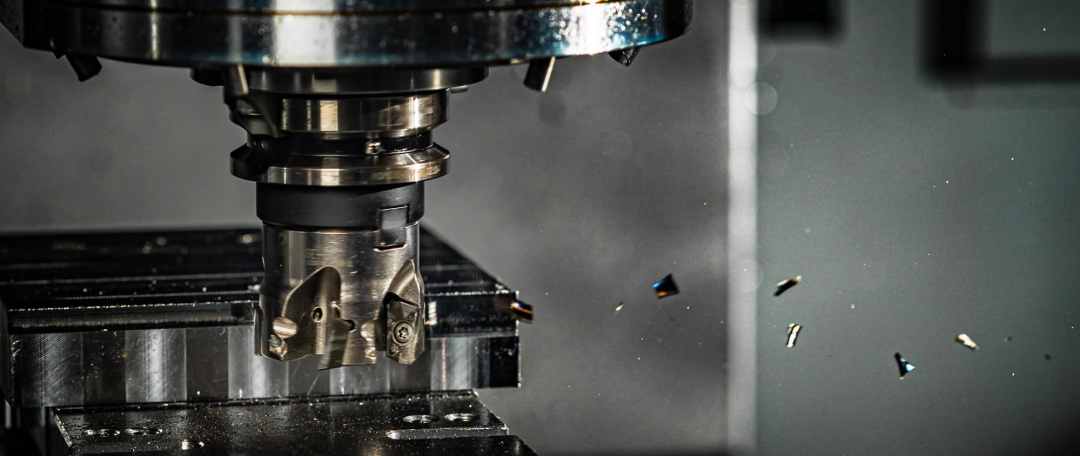

6. Enhanced Surface Finish

Another advantage of these machines is the superior surface finish they can achieve. With multi-axis capabilities, tools can engage the workpiece from optimal angles, resulting in a smoother and more refined finish.

7. Reduction of Manual Interventions

The advanced technology in multi-axis milling machines reduces the need for manual interventions. This automation not only speeds up the process but also minimizes the chances of human errors, ensuring consistent quality.

8. Excellent Repeatability

The repeatability of multi-axis milling machines is terrific. Once the machine is programmed, it can replicate the same process with the same level of accuracy over countless cycles, which is vital for mass production.

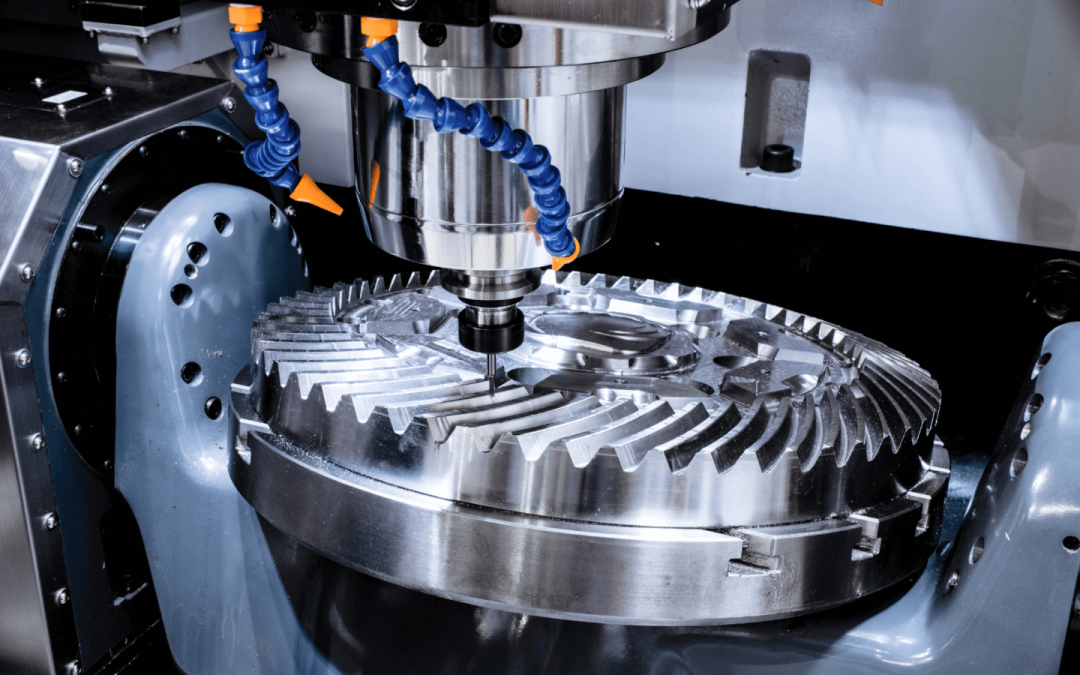

9. Complex Geometries

These machines excel at producing complex geometries that would be difficult or impossible with traditional milling methods. This capability opens up new possibilities for innovative designs and applications.

10. Space-Saving Benefits

In many cases, industry professionals find that multi-axis machines consolidate various functions into a single machine, saving valuable floor space in manufacturing facilities.

11. Ergonomics and Operator Safety

Safety is paramount in manufacturing. Multi-axis milling machines often feature advanced safety protocols, ensuring that operators are less exposed to potential hazards. Improved ergonomics also lead to a healthier working environment.

12. Lower Tooling Costs

Due to the versatility and precision of multi-axis milling machines, the tooling required is often less complex and costly. This reduction in tooling cost can be a significant financial benefit for many businesses.

13. Integration With Modern Technology

These machines integrate seamlessly with modern technologies like CNC programming and CAD/CAM software. This compatibility makes them highly efficient and easy to incorporate into existing workflows.

14. Future-Proofing Your Assets

As industries continue to evolve, staying ahead with cutting-edge technology ensures that your operations remain competitive. Investing in multi-axis milling machines is a smart move to future-proof your manufacturing processes.

15. Industry-Specific Applications

From aerospace to electronics, multi-axis milling machines find applications across various industries. Their ability to handle specialized tasks makes them indispensable in many sectors.

FAQ

Q1: What materials can be used with multi-axis milling machines?

A1: These machines can handle a wide range of materials, including metals, plastics, and composites, making them incredibly versatile.

Q2: How does a multi-axis milling machine improve efficiency?

A2: By performing multiple operations in a single setup, these machines significantly reduce the time required for production, thus improving overall efficiency.

Q3: Are multi-axis milling machines cost-effective?

A3: Yes, despite the high initial investment, the long-term benefits such as reduced labor costs and minimal waste make these machines cost-effective.

For those interested in learning more about other high-speed technologies, do visit inspection and analysis.