In the world of manufacturing, the advent of multi-axis milling machines has brought about tremendous advancements. These machines integrate complex movements that allow for intricate milling tasks. However, despite their capabilities, its essential to understand what are the disadvantages of a multi-axis milling machine to ensure informed decision-making in your business operations.

Multi-axis milling machines have become integral in numerous industries due to their ability to perform diverse tasks. Nonetheless, they come with their share of drawbacks. This article aims to delve deeply into the challenges associated with these sophisticated machines.

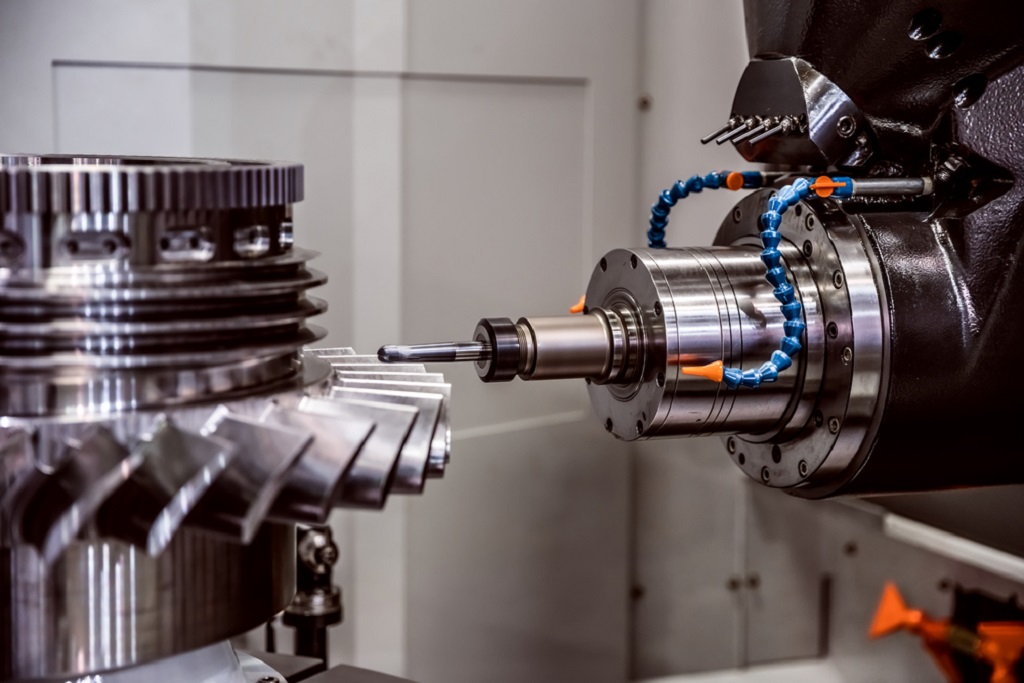

The Complexity of Multi-Axis Milling Machines

The first notable disadvantage is the complexity of multi-axis milling machines. Their intricate nature often translates to steeper learning curves for operators and technicians. A detailed understanding of CNC programming and machine-operating skills is required, making the training process extensive and costly.

High Cost of Acquisition and Maintenance

Another crucial factor to consider is the substantial cost associated with these machines. The initial acquisition cost is significantly higher compared to traditional milling machines. Additionally, the upkeep and maintenance of these machines are also expensive. Regular servicing by professionals is necessary to keep them operating efficiently.

Sensitivity to External Conditions

Multi-axis milling machines are highly sensitive to external conditions such as temperature fluctuations, dust, and humidity. These environmental factors can affect the precision and accuracy of the machine, thereby impacting the quality of the finished product.

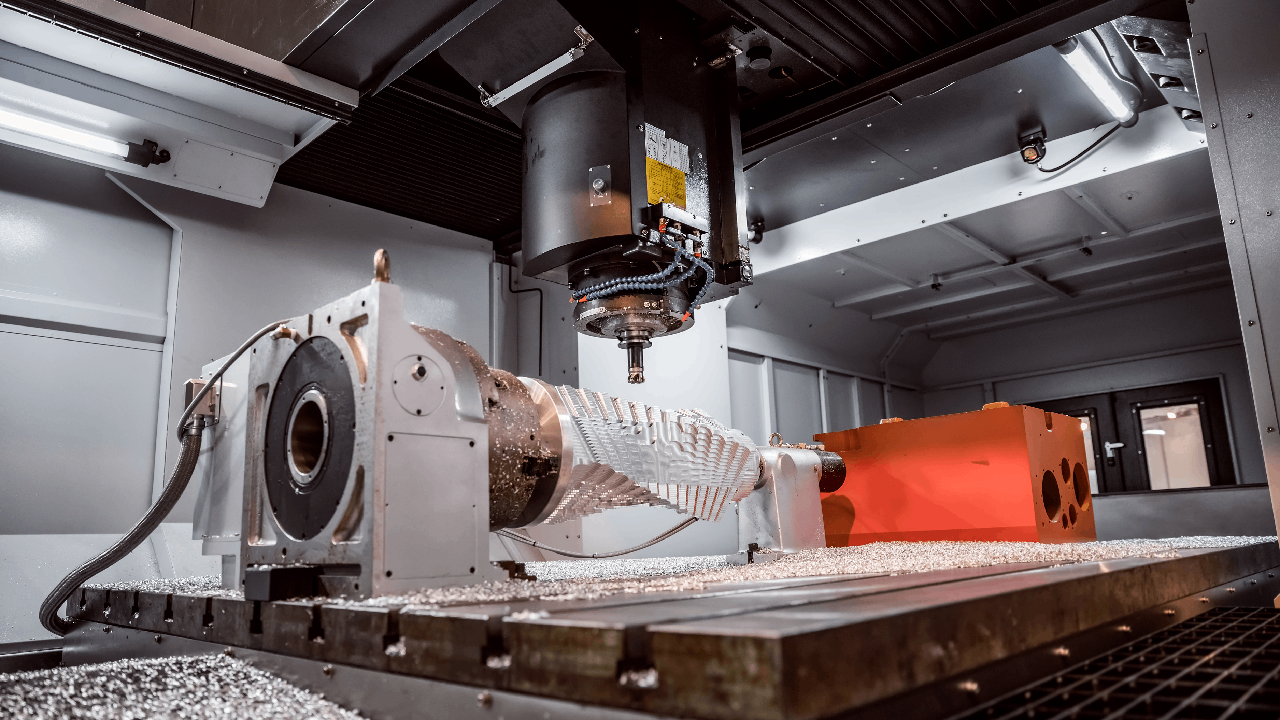

Operational Challenges

Operational challenges also make it onto the list of disadvantages. These machines demand a controlled environment and frequent calibration. Any deviation can lead to errors, affecting the overall productivity. Moreover, troubleshooting these advanced machines requires in-depth technical knowledge.

Energy Consumption

Multi-axis milling machines consume more energy compared to their single-axis counterparts. The high power demand can result in increased operational costs, making them less economical in the long run.

Programming Complexity

The programming for multi-axis milling machines is another area where complexities arise. Advanced software and detailed code writing are necessary to optimize the functionality of these machines. Errors in programming can be difficult to detect and may result in significant downtime.

Impact on Small Businesses

While multi-axis milling machines are advantageous in large-scale manufacturing setups, their disadvantages can be a hurdle for small businesses. The high initial cost, maintenance expenses, and need for skilled operators can strain the resources of smaller enterprises.

Integration with Existing Systems

Integrating a multi-axis milling machine with existing systems can also pose challenges. Compatibility issues may arise with older software or machinery, necessitating additional investments in upgrades and training.

Material Waste

Although these machines are known for their precision, the initial setups and trials can lead to material wastage. Optimizing the milling process requires several iterations, resulting in increased material costs.

Health and Safety Concerns

Health and safety are paramount in any manufacturing environment. Multi-axis machines, due to their advanced operations, pose specific safety risks. Proper training and strict adherence to safety protocols are necessary to prevent accidents.

Noise and Vibration

The operation of multi-axis milling machines often generates noise and vibration, which can be a concern for the workforce. Prolonged exposure to high levels of noise can lead to hearing problems, necessitating the use of protective gear.

Risk of Operational Errors

Given their complexity, there is a higher risk of operational errors. Mistakes in setup or programming can lead to accidents or defects in the finished products, emphasizing the need for meticulous attention to detail.

Long-Term Viability

Considering the rapid technological advancements, the long-term viability of investing in multi-axis milling machines is a concern. Businesses must evaluate whether these machines can adapt to future technological shifts and maintain their relevance.

Depreciation

Like any advanced machinery, multi-axis milling machines depreciate over time. Companies should consider the resale value and anticipate potential losses in value.

Future Proofing

Staying future-proof requires continuous investments in training, software updates, and machine upgrades. This ongoing commitment may be daunting for businesses with limited budgets.

Comparing Alternatives

Understanding the disadvantages of multi-axis milling machines prompts a comparison with alternative solutions. While these machines offer superior capabilities, evaluating alternatives based on specific needs and resources is crucial.

Single-Axis Machines

For simpler operations, single-axis milling machines may suffice. They come at a lower cost, are easier to operate, and require less maintenance. [Learn more about the advantages of CNC machines over others](https://strobox.ai/what-are-the-advantages-of-cnc-machines-over-machines-like-lathes-3/)

Conclusion

While multi-axis milling machines offer advanced capabilities, it is essential to weigh their disadvantages carefully. From high costs and operational challenges to the impact on small businesses and health risks, understanding these drawbacks can lead to more informed decisions. Striking a balance between the benefits and disadvantages will help you leverage the technology effectively.

FAQs

What training is required for operating multi-axis milling machines?

Extensive training in CNC programming and machine operation is essential. Operators must be well-versed with the machine’s intricate functionalities and safety protocols.

Are multi-axis milling machines suitable for all manufacturing scales?

These machines are more suited to large-scale manufacturing due to their high cost and operational requirements. Small businesses might find the expenses challenging to manage.

What are the common maintenance needs for multi-axis milling machines?

Regular servicing by professionals, calibration, and monitoring of environmental conditions are crucial. Proper maintenance ensures the machine operates efficiently and extends its lifespan.