The significance of milling machines in the industrial sector is tremendous. A milling machine is one of the most indispensable machines in the manufacturing industry. But, what exactly can you make with a milling machine? Let’s dive in and find out. The utilization of this technology is vast and equally exciting.

Introduction to Milling Machines

Milling machines have been around for centuries and are continuously evolving. These machines are used to machine solid materials like metal and wood. Big industries are delighted with their versatility and precision. They come in various types and configurations, allowing for a wide range of applications.

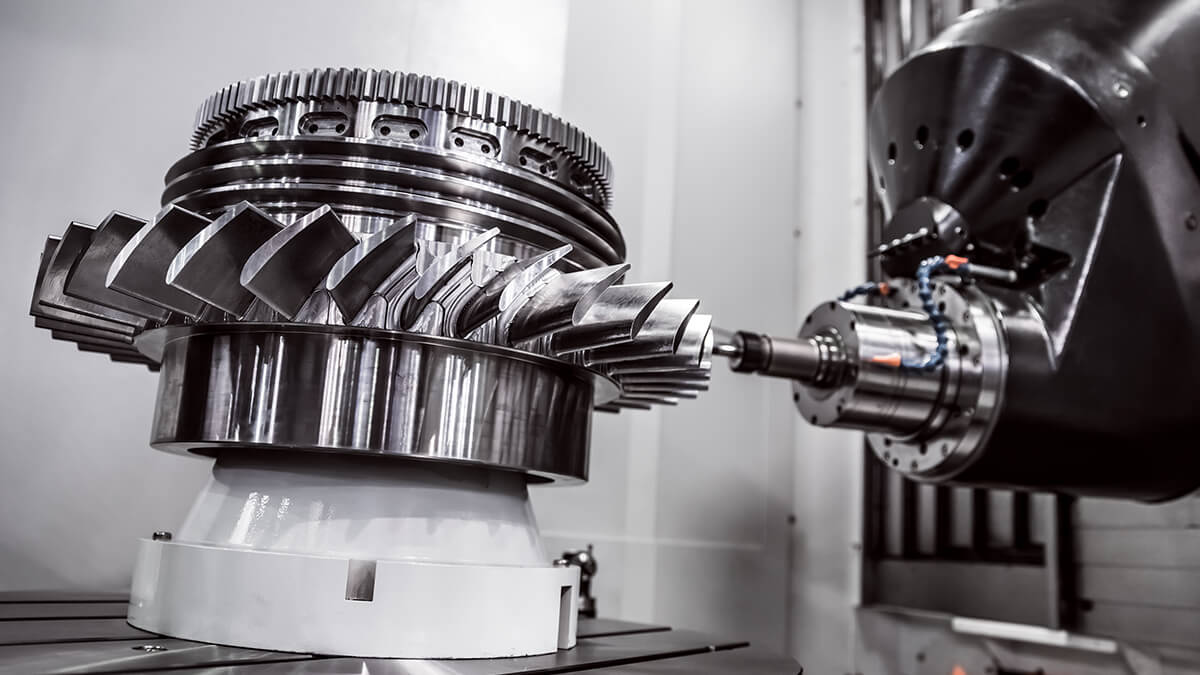

Components of a Milling Machine

Main Components

Understanding the core components of a milling machine can help explain its importance. These components include:

- Spindle: This is the part that holds and rotates the cutting tool.

- Table: A platform that holds the workpiece.

- Knee: The component that supports the table and can be adjusted vertically.

- Saddle: Sits on the knee and supports the table.

- Column: The major structural component that holds the whole machine together.

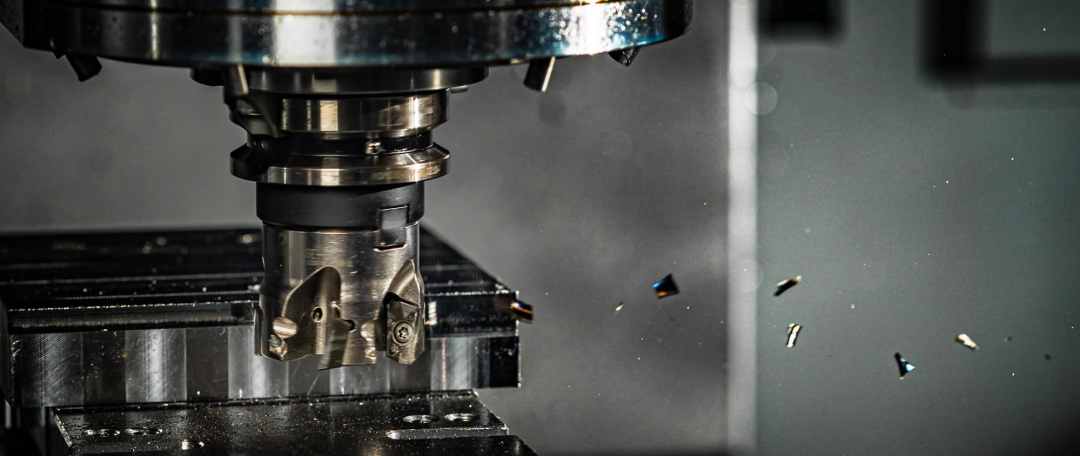

Cutting Tools

Various cutting tools are used in milling machines. Some of the common ones include end mills, face mills, and slot drills. Each has a specific task and, when used correctly, can produce tremendous results.

Applications in the Manufacturing Industry

Automotive Industry

Milling machines are vital in the automotive industry. They are used to create precise parts for engines, transmissions, and other crucial components. The technology has revolutionized how car parts are made.

Aerospace Industry

The aerospace industry relies heavily on milling machines to create complex aircraft parts with tight tolerances. These machines ensure the reliability and safety of aircraft.

Medical Devices

High precision and hygiene are crucial in the medical field. Milling machines are used to manufacture intricate medical devices like implants and surgical instruments.

Electronics Industry

The electronics industry benefits from the precision milling machines offer. They are used to create detailed and small components for electronic gadgets.

Everyday Items Created by Milling Machines

Custom Parts and Tools

From simple tools to complex parts, milling machines can create a variety of custom items that are used in everyday life.

Prototyping

Prototyping is another tremendous application. Milling machines can quickly create prototypes for testing and development, proving their importance in innovation.

Modern Advancements in Milling Technology

CNC Milling Machines

CNC milling machines are the modern marvel of the milling world. They offer precision, speed, and versatility unmatched by manual milling machines.

High-Speed Milling

High-speed milling technology shortens production times and increases efficiency. This is particularly beneficial for high-volume manufacturing.

Learning to Use a Milling Machine

Basic Training

Anyone can learn to use a milling machine with basic training. Many vocational schools and community colleges offer courses in machining.

Advanced Skills

Developing advanced skills in milling can lead to tremendous career opportunities. Specialized training programs are available for those wishing to delve deeper.

Conclusion

Milling machines are indispensable in today’s manufacturing world. From producing simple parts to intricate components, the possibilities are endless. Understanding what you can make with a milling machine opens a world of innovation and efficiency.

Frequently Asked Questions

What materials can be machined using a milling machine?

Milling machines can machine various materials, including metals, plastics, and wood. The choice of material depends on the cutting tool and the machine’s capabilities.

Is it difficult to learn how to use a milling machine?

While there is a learning curve, basic training can help anyone get started. Advanced skills may require specialized training and experience.

What are the benefits of CNC milling machines?

CNC milling machines offer high precision, versatility, and efficiency. They can produce complex parts quickly and accurately.