The advent of the milling machine marked a significant milestone in the field of manufacturing and machining. When we ask, ‘what did people do before the milling machine?’, we open a gateway into the rich, layered history of human ingenuity that predates modern machining technology. This article serves not only to answer that question but also to shed light on how people managed machining tasks before the renowned invention of the milling machine.

Breaking this down into manageable sections, we’ll explore various methods, tools, and technologies that were employed before the advent of milling machines. Let’s journey into the remarkable world of pre-milling machine practices to understand how the relentless pursuit of precision has driven human innovation over the centuries.

The Importance of Milling Machines

Modern-Day Relevance

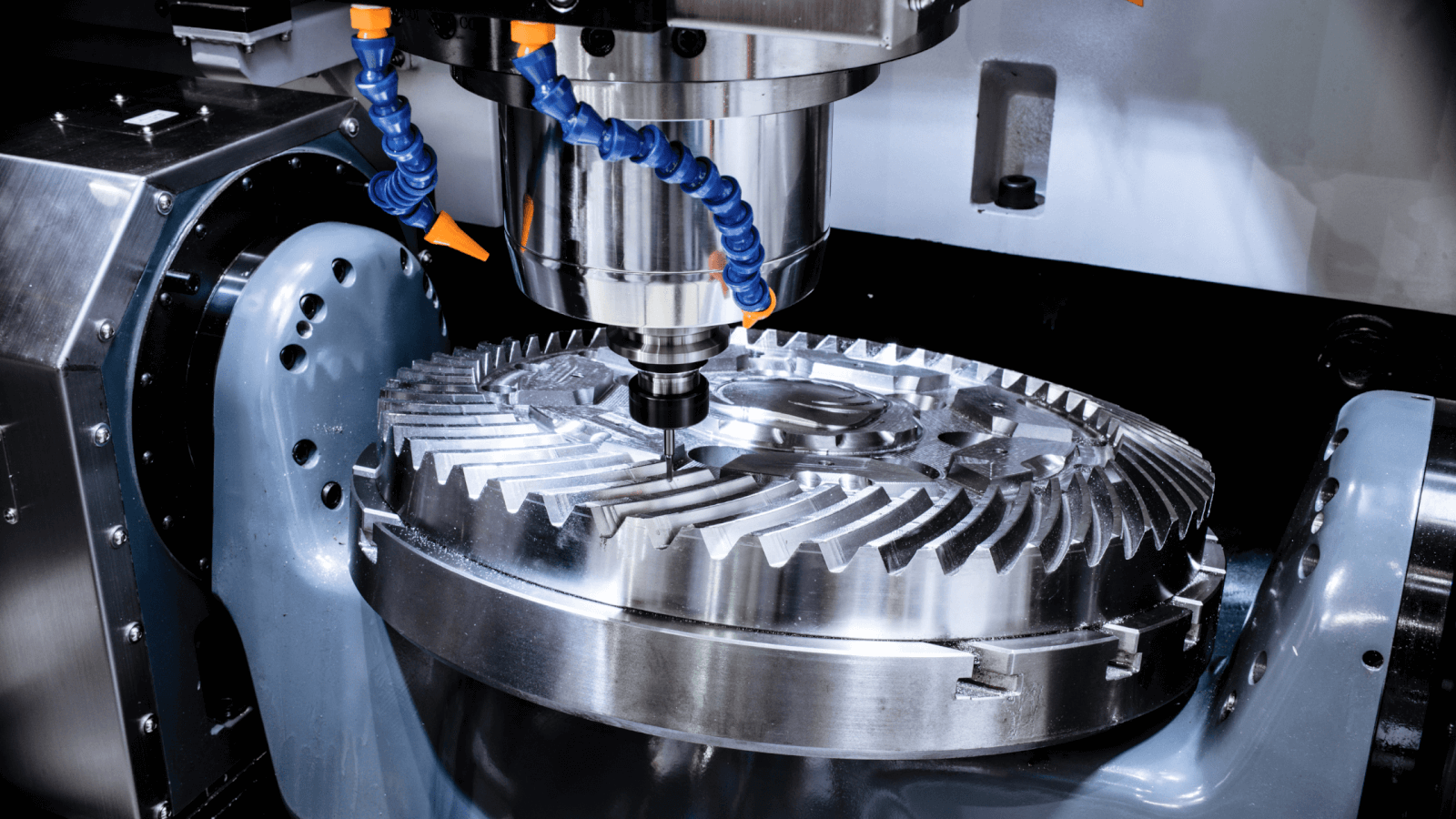

Milling machines today are at the forefront of manufacturing in various industries, including automotive, aerospace, and electronics. The need for precision and efficiency has never been more paramount, which makes the history behind these machines even more intriguing and worthy of exploration.

Hand Tools and Their Evolution

Early Human Tools

Before the milling machine, one of the earliest tools humans used to shape materials was the hand tool. Simple yet effective tools like chisels and hammers allowed early civilizations to carve and shape wood, stone, and later metals.

The Chisel and Hammer Method

Used in ancient Egypt and Mesopotamia, chisels and hammers were primary tools to shape intricate engravings and mortise joints essential for building structures and statues. They demanded high precision, much like today’s machining tools.

Manual Filing Methods

The Simplicity of Filing

Filing was another critical method used before milling machines. Files had a significant role in maintaining the required dimensions and smooth surfaces of metal parts. This manual method required a keen eye for detail and a steady hand.

Lathe Machines Predecessors

Early Lathe Tools

Lathe machines have a long history dating back to ancient Egypt. Initially, they were operated manually, often using a bow mechanism. This technology evolved and became one of the cornerstones of early industrial machining.

Forging and Casting Techniques

The Role of Blacksmiths

Blacksmiths were the engineers of their time, using heat to manipulate metal workpieces. They utilized techniques like forging and casting to create complex shapes and parts, long before milling or drilling machines became commonplace.

Sand Casting

Ancient civilizations used sand casting methods to produce metal parts. This process involved creating a mold out of sand, pouring molten metal into it, and allowing it to solidify.

Hand-Cranked Saws and Planers

Pre-Milling Saws

Before the advent of powered machinery, saws and planers that were manually operated played significant roles in shaping wood and metal parts. These tools laid the groundwork for the development of more complex machinery.

The Renaissance and Technological Shifts

Leonardo da Vinci’s Contributions

During the Renaissance, there was a surge in technological innovations. Leonardo da Vinci sketched several machine concepts, including a version of a milling machine, which laid the foundation for future developments.

Early Milling Techniques

Water-Powered Mills

In the pre-industrial era, water wheels powered basic milling and grinding operations. This technology signaled a significant advancement in automation, reducing the need for manual labor and increasing productivity.

The Industrial Revolution

Mechanization of Tools

The Industrial Revolution marked a turning point with the introduction of steam-powered machines. This period saw the development of more advanced tools, including rudimentary versions of milling machines.

The Art of Machining

The Rise of Precision

Before the milling machine, the art of machining was highly manual and required an incredible degree of skill. Craftsmen relied on their senses and extensive experience to create precise parts and components.

Comparative Analysis

Manual vs. Modern Methods

When comparing manual methods to todays milling machines, the difference is striking. Modern machines provide unparalleled precision and efficiency, but the core principles of shaping and material removal remain the same.

Significance and Legacy

Cultural Impact

The tools and techniques preceding the milling machine significantly impacted various cultures. For example, ancient structures and artifacts exhibit a high level of craftsmanship achieved with rudimentary tools, reflecting the ingenuity of the people.

Historical Landmarks

Before milling machines, wonders like Egyptian pyramids and Roman aqueducts were built, showcasing the engineering marvels that humans could achieve with the tools available at their time.

Modern-Day Applications

Where We Are Now

Today, milling machines are essential in various sectors. For instance, in the semiconductor industry, tools like high-speed paint and coating application inspection and high-speed semiconductor manufacturing inspection rely on advanced milling techniques.

Additionally, emerging technologies such as high-speed genetic analysis and sequencing monitoring [dofollow] sequence analysis and high-speed semiconductor wafer polishing inspection continue to push the boundaries of precision and efficiency.

The Future of Machining

Technological Advancements

With continuous innovation, the future of machining looks promising. Advanced stroboscopic event detection in semiconductor wafer polishing is one such field where substantial progress is being made.

For more on the basics of milling machines, you can reference this [external article](https://landmarktools.com/blogs/guides/what-is-a-milling-machine-everything-you-need-to-know?srsltid=AfmBOoqOuPRlpxydEQevn5V_opmiUwCa5CNmDeyBn7bm7p0PEAm6SXdD) on understanding milling machines.

Conclusion

Understanding ‘what did people do before the milling machine’ helps appreciate the evolution of machining technology. The journey from hand tools to advanced milling machines underscores human ingenuity and the relentless pursuit of improvement. As we continue to innovate, remembering our technological roots can inspire future advancements.

Frequently Asked Questions (FAQ)

1. What was a chisel used for?

Chisels were used for carving and shaping various materials, especially wood and stone. They played a crucial role before the advent of advanced machining tools.

2. How important was filing in pre-milling machine times?

Filing was crucial for achieving precise dimensions and smooth finishes on metal parts. It was a manual process requiring skill and patience.

3. Did early lathe machines influence modern milling technology?

Yes, early lathe machines significantly influenced the design and development of milling machines. Their principles laid the groundwork for later technological advancements.