When we talk about manufacturing and machining, the first question that often arises is ‘what does a milling machine do’? These machines are tremendous in their application and technology, making them valuable assets in various industries. Essentially, a milling machine is designed to shape, cut, and drill materials, primarily metal, to create components for a variety of products. In this article, we will delve into the specifics of their functions and uses.

The Evolution and Importance of Milling Machines

Milling machines have come a long way since their inception in the early 19th century. Initially used for simple cutting tasks, they have evolved into highly sophisticated devices through advancements in technology. This evolution has widened their application across different sectors, making them indispensable in manufacturing and engineering fields. For a more detailed history of milling machines, you can check out this extensive article on Wikipedia.

Types of Milling Machines

Vertical Milling Machines

These machines feature a vertically oriented spindle that holds and rotates the cutting tool against the workpiece. They are known for their ability to perform highly detailed and precise work, which makes them ideal for tasks requiring intricate designs.

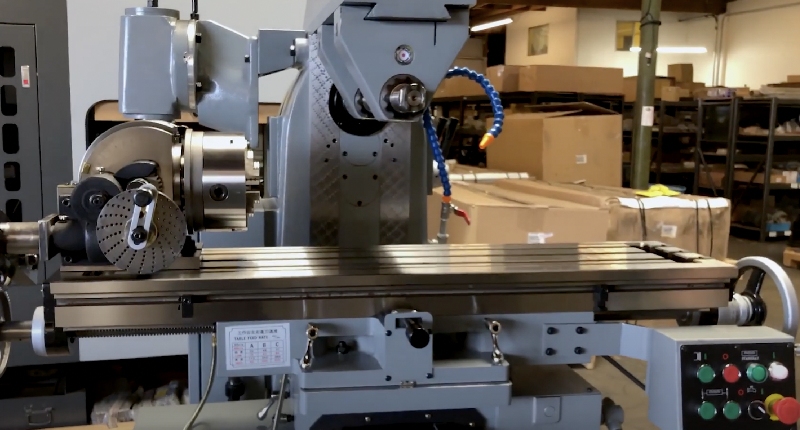

Horizontal Milling Machines

Unlike their vertical counterparts, horizontal milling machines have a horizontal spindle. This orientation allows them to handle heavier and larger workpieces, perfect for tasks that require more robust construction and greater cutting volume.

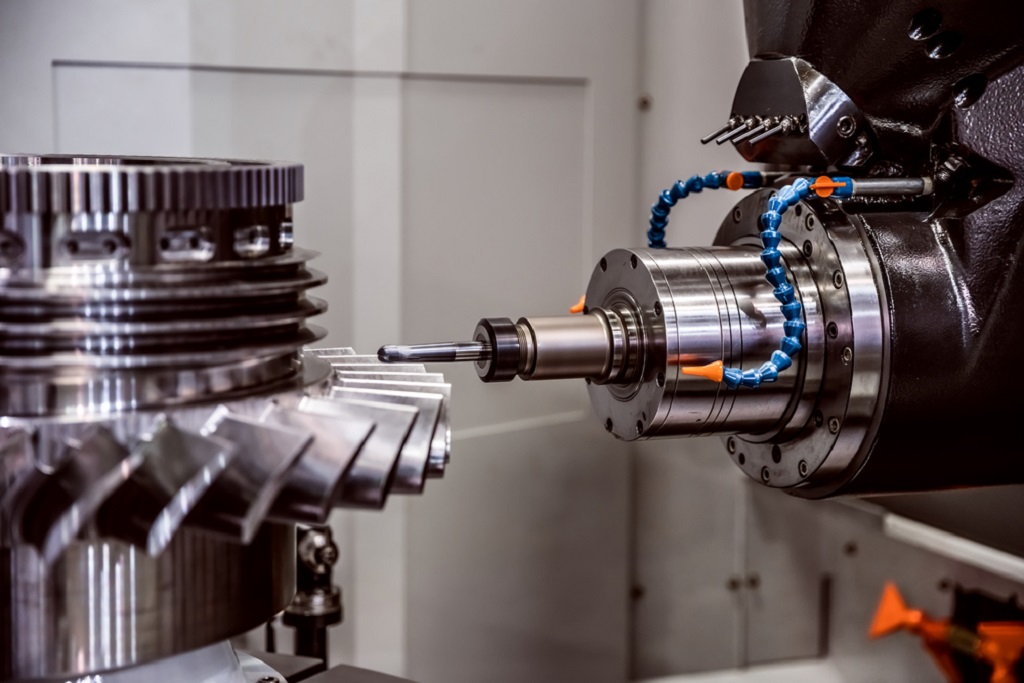

CNC Milling Machines

CNC (Computer Numerical Control) milling machines are the epitome of modern machining technology. These machines are equipped with computer systems that automate the milling process, ensuring accuracy and efficiency. If you are curious about the advantages of CNC machines over traditional ones, this article might be a great read.

Core Functions of a Milling Machine

Facing and End Milling

Facing is a process where the milling machine cuts across the top surface of a material to create a flat area. End milling, on the other hand, involves cutting along the edge of the material, often to create slots and holes.

Drilling and Boring

Milling machines can also be used for drilling and boring purposes. Drilling involves making round holes in materials, while boring is the process of enlarging those holes for specific applications.

Slotting and Broaching

In addition to cutting and drilling, milling machines can perform slotting and broaching. Slotting involves creating elongated holes or channels, while broaching is used for shaping and finishing edges and surfaces.

Industries That Rely on Milling Machines

Aerospace

The aerospace industry extensively uses milling machines for creating complex and precise components. These machines ensure that every part meets stringent quality standards, which is essential for air safety.

Automotive

Milling machines play a significant role in the automotive industry. They are used for manufacturing everything from engine components to intricate parts of car bodies.

Semiconductor Manufacturing

In the semiconductor industry, the need for precision is paramount. Milling machines help in cutting, shaping, and forming semiconductor wafers, ensuring each piece meets the required specifications. For more on the role of milling in this industry, consider this resource.

Safety Measures While Using a Milling Machine

Personal Protective Equipment (PPE)

When operating a milling machine, it’s crucial to wear appropriate PPE, such as safety goggles, gloves, and hearing protection. These measures help protect against the hazards posed by flying debris and loud noise.

Regular Maintenance

Routine maintenance of milling machines ensures they operate efficiently and safely. Regularly checking for wear and tear, lubricating moving parts, and calibrating the machine can significantly extend its lifespan.

Proper Training

Operators must be adequately trained to use milling machines safely. This includes understanding the machine’s components, operating procedures, and emergency protocols.

Advantages of Using a Milling Machine

High Precision

One of the primary advantages of milling machines is their ability to produce highly precise and intricate parts. The accuracy achieved by these machines is unmatched, making them essential in industries where every millimeter counts.

Versatility

Milling machines are incredibly versatile. They can perform a wide range of tasks, from cutting and drilling to shaping and finishing. This makes them a valuable asset in various industries.

Efficiency

With advancements in technology, modern milling machines are highly efficient. CNC milling machines, in particular, can perform multiple tasks simultaneously, reducing the time and effort required for complex projects.

Challenges and Limitations

Initial Cost

The initial cost of setting up a milling machine can be high, especially for advanced CNC models. However, the long-term benefits often outweigh the initial investment.

Skill Requirement

Operating a milling machine requires a certain level of skill and expertise. This includes understanding the machine’s functions, reading technical drawings, and programming CNC machines.

Space Requirement

Milling machines can be quite large, requiring significant space for installation and operation. This can be a limitation for small workshops or facilities with limited space.

Future of Milling Machines

As technology continues to advance, the future of milling machines looks promising. Innovations in automation, artificial intelligence, and advanced materials are expected to revolutionize the field, making milling machines even more versatile and efficient.

FAQs

What materials can be milled?

Milling machines can work with a variety of materials, including metals, plastics, and wood.

How long does it take to learn to operate a milling machine?

The time required to learn to operate a milling machine varies depending on the complexity of the tasks and the operator’s experience. However, basic operations can be learned in a few weeks with proper training.

Is regular maintenance required for milling machines?

Yes, regular maintenance is crucial for ensuring the efficiency and longevity of milling machines. This includes routine checks, lubrication, and calibration.