In our fast-paced world, keeping track of precise measurements is vital. One such critical instrument is the tachometer. So, what does a tachometer indicate? This article dives deep into the world of tachometers and what they signify, shedding light on their significance in various industries, particularly quality assurance (QA).

Introduction to Tachometers

A tachometer is a revolutionary instrument that measures the rotational speed of an object, usually a shaft or a disk, in a motor or other mechanical device. It displays this speed in revolutions per minute (RPM). This feature makes it an invaluable tool across many fields.

How a Tachometer Works

At its core, a tachometer measures the frequency of rotations. The device can be analog, with a needle and dial, or digital, with a more modern display. By measuring the speed of rotation, it offers data critical to ensuring machinery operates within optimal parameters.

Importance in Quality Assurance

Quality assurance professionals must ensure products meet certain standards. Tachometers provide essential data to maintain these standards, particularly in manufacturing. Accurate readings help in monitoring processes, identifying potential issues, and ensuring consistent quality.

High-Speed Inspections

In high-speed environments, such as wafer polishing, paint and coating, genetic analysis, and semiconductor manufacturing, the role of tachometers is indispensable.

Ensuring Efficiency

Efficiency is critical in any industry. By measuring RPM accurately, tachometers assist in maintaining machinery at peak performance, reducing downtime and wear and tear.

Types of Tachometers

Tachometers can be categorized into various types based on their functionality and application:

- Analog Tachometers: Traditional devices with a dial and needle.

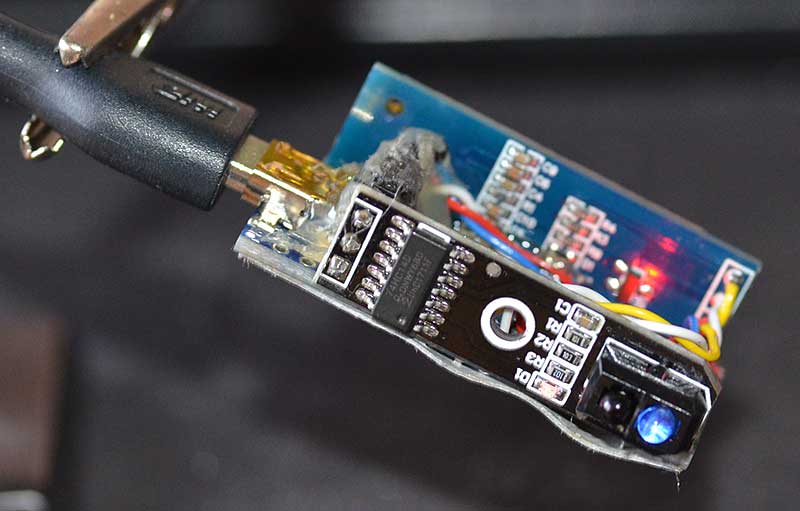

- Digital Tachometers: Modern devices with an LCD or LED display.

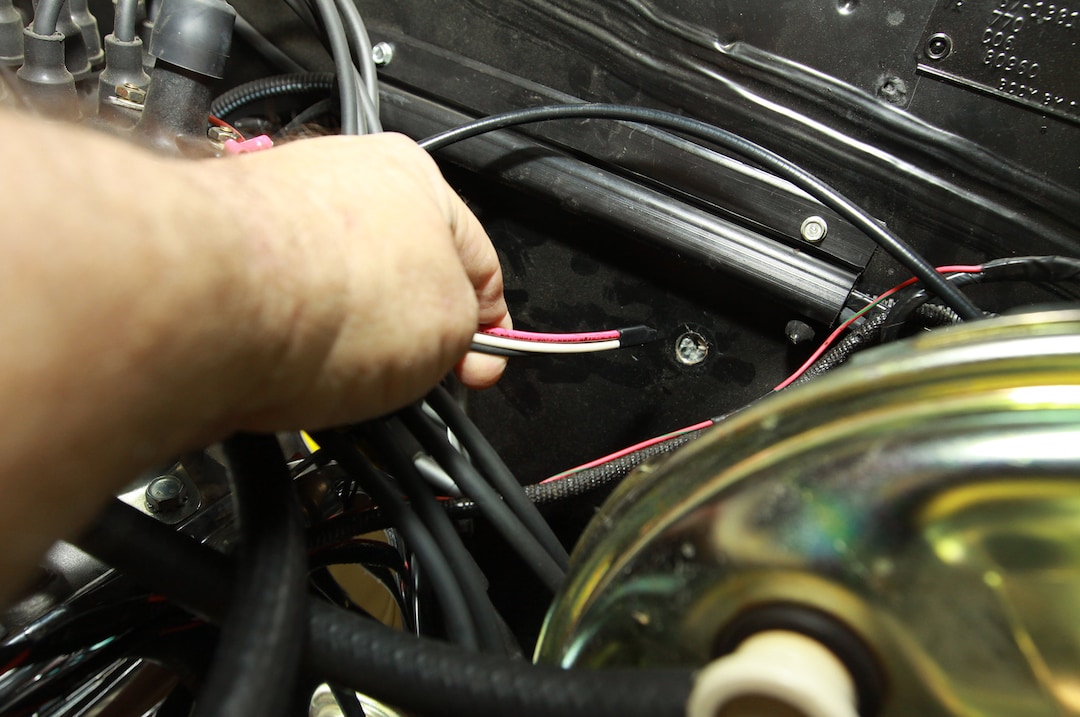

- Contact Tachometers: Directly contact the rotating component.

- Non-Contact Tachometers: Use a laser or optical method to measure speed.

Applications in Different Industries

The use of tachometers extends across various industries:

- Automotive: Monitoring engine speed to ensure optimal performance.

- Manufacturing: Ensuring machinery operates within designated RPM ranges.

- Aerospace: Critical for monitoring aircraft engine performance.

- Medical: Used in devices like centrifuges and other lab equipment.

Benefits of Using Tachometers

The advantages of using a tachometer are numerous:

- Accuracy: Provides precise RPM readings essential for quality control.

- Preventive Maintenance: Helps in identifying issues before they become critical.

- Efficiency: Ensures machinery operates at optimal rates, reducing energy consumption.

Understanding Readings and Data

Interpreting tachometer readings can be straightforward:

An analog tachometer displays readings via a needle on a dial, while digital versions show numbers on a screen.

Challenges in Using Tachometers

While tachometers are beneficial, they do come with challenges:

- Calibration: Needs regular calibration to maintain accuracy.

- Sensitivity: Can be affected by external factors like vibrations and temperature.

Future of Tachometer Technology

As technology advances, so does the future of tachometers. We can expect more integration with smart devices, cloud-based monitoring, and advanced analytics to make these devices even more powerful.

Case Study: Tachometers in Semiconductor Industry

In the semiconductor industry, tachometers play a pivotal role. Ensuring the precise rotation of wafers is critical for quality and performance. For more details, visit Wikipedia on Tachometers.

Conclusion

Understanding what a tachometer indicates is crucial for anyone involved in maintaining or monitoring rotational machinery. Whether in automotive, manufacturing, aerospace, or medical fields, tachometers ensure that machinery operates efficiently and safely.

FAQ

1. What is a tachometer used for?

A tachometer measures the rotational speed of an object, typically an engine or other mechanical component, providing data in RPM.

2. How does a tachometer help in quality assurance?

By providing accurate RPM measurements, tachometers help maintain machinery performance, ensuring standards are met and identifying potential issues before they escalate.

3. What types of tachometers are there?

Tachometers can be analog or digital, contact or non-contact, each with specific applications based on the need and environment.