The tachometer is a critical instrument in many mechanical and automotive systems. In this comprehensive guide, we dive deep into understanding what a tachometer indicates and why it plays a crucial role in various industries. Whether you’re an industry QA professional or just a curious reader, this article will illuminate the significant aspects of tachometers.

Introduction to Tachometers

In essence, a tachometer is an instrument that measures the rotation speed of a shaft or disk. It is typically found in motors, vehicles, and myriad mechanical devices. When you ask what does a tachometer indicate?, youre essentially inquiring about the device’s primary function: to measure and indicate the revolutions per minute (RPM).

The Importance of Tachometers in Industry

Tachometers play a vital role in multiple industries, helping professionals ensure equipment operates within optimal RPM ranges. For instance, in the automotive industry, a tachometer helps drivers monitor engine speed, preventing potential damage due to over-revving. In manufacturing, it ensures that machinery runs efficiently without exceeding safe operating speeds.

Applications in the Automotive Industry

In cars, tachometers are crucial for monitoring engine speed. Maintaining the vehicle within the recommended RPM range ensures efficient fuel consumption and prolongs engine life. It is an indispensable tool for both everyday drivers and professionals who rely on tactical vehicle performance.

Applications in Manufacturing

Tachometers are equally important in manufacturing settings. They are used to monitor and maintain the speed of machinery, ensuring consistency and safety in operations. For a detailed overview of its application, check out Semiconductor Manufacturing.

How Does a Tachometer Work?

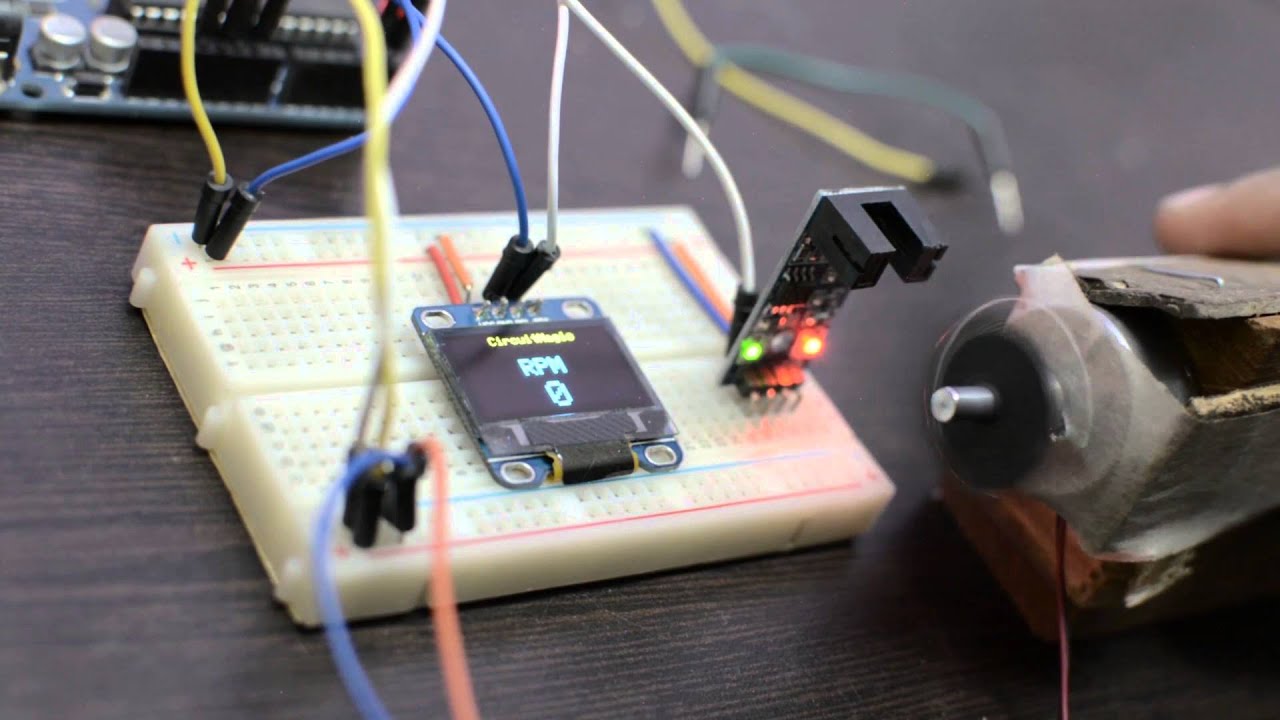

Understanding the inner workings of a tachometer can be fascinating. The device operates by calculating the time interval between pulses generated by the moving part it monitors. This calculation is then converted into RPM, providing real-time data to the user.

Types of Tachometers

There are several types of tachometers, each suited for different applications:

- Analog Tachometers: These traditional tachometers use a needle and dial to display RPM.

- Digital Tachometers: More modern and accurate, these use digital displays to provide precise readings.

- Contact and Non-Contact Tachometers: Contact tachometers require physical contact with the rotating part, while non-contact versions use laser or optical methods for measurement.

What Does a Tachometer Indicate in Different Contexts?

Beyond simple RPM readings, tachometers can indicate a wealth of operational data, including:

Engine Health

A steady, consistent RPM reading typically indicates a healthy engine. Fluctuations or unexpected spikes can signal potential issues. This is crucial information for mechanics and vehicle owners alike.

Machine Efficiency

In industrial settings, tachometers help monitor the efficiency of machinery. A machine running within its optimal RPM range is more efficient and less likely to suffer wear and tear.

The Evolution of Tachometers

Over the years, tachometers have evolved from simple mechanical devices to complex electronic instruments. This evolution has made them more accurate and versatile, capable of integrating with other systems for comprehensive monitoring and control. To learn more about the history and advancements in tachometer technology, visit AZoSensors.

Mechanical Tachometers

The earliest tachometers were purely mechanical, using gears and springs to measure RPM. While they were relatively accurate, they required regular maintenance and calibration.

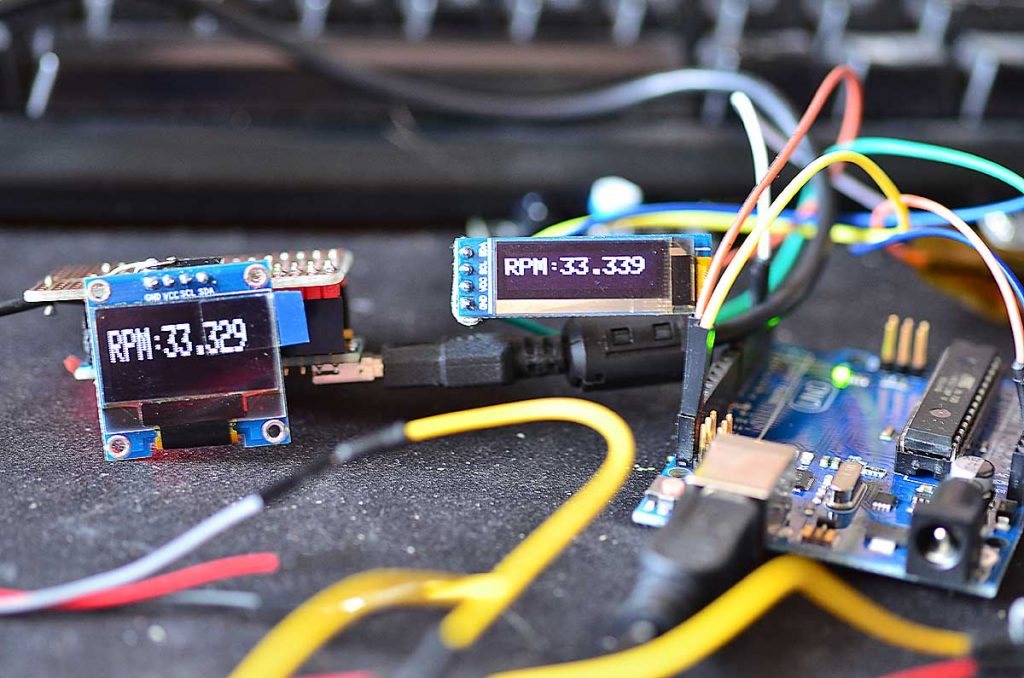

Electronic and Digital Tachometers

Modern tachometers use electronic sensors and digital displays, offering greater accuracy, reliability, and ease of use. Their integration with other electronic systems allows for more comprehensive data analysis and monitoring.

Why Tachometers Are Indispensable Tools

Tachometers are indispensable in many applications because they provide critical data that can prevent equipment failure, optimize performance, and ensure safety. For instance, in high-speed genetic analysis, precise RPM control is vital. For more insights, check out Genetic Analysis.

Key Benefits

The benefits of using tachometers include improved equipment lifespan, enhanced performance, and increased safety. By monitoring RPM, operators can make informed decisions to maintain optimal operating conditions.

Industry Standards and Calibration

To ensure accuracy, tachometers must conform to industry standards and require regular calibration. Calibration involves adjusting the instrument to correlate with an established standard. Information on calibration can be found on Tesca Global.

Calibration Processes

Calibration typically involves comparing the tachometer’s readings against a known standard and making necessary adjustments. This process ensures the device provides accurate and reliable data.

Common Issues and Troubleshooting

Like any instrument, tachometers can experience issues. Common problems include inaccurate readings or complete failure. Identifying and troubleshooting these issues promptly is crucial for maintaining system reliability.

Inaccurate Readings

Inaccuracy can result from various factors, including sensor wear, improper calibration, or environmental conditions. Regular maintenance and calibration can help mitigate these issues.

Device Failure

Complete failure, though rare, can occur due to mechanical damage or electronic faults. In such cases, replacing or repairing the tachometer is necessary. For reliable information on maintenance, visit Tachometer System.

Choosing the Right Tachometer

Selecting the right tachometer depends on the application’s specific requirements. Consider factors such as accuracy, range, and type (analog or digital) to find the best fit for your needs.

Application Requirements

Different applications require different specifications. For instance, high-speed applications might need non-contact digital tachometers, while standard machinery might suffice with analog versions. Explore more options in Paint and Coating Applications.

Budget Considerations

Budget is always a consideration. While digital tachometers tend to be more expensive, they offer greater accuracy and features, making them a worthwhile investment for critical applications.

Conclusion

Understanding what a tachometer indicates is essential for anyone involved in industries relying on precise RPM measurements. From automotive to manufacturing, tachometers play a critical role in ensuring equipment efficiency, performance, and safety.

FAQs

What does a tachometer indicate?

A tachometer indicates the rotation speed of a shaft or disk in RPM (revolutions per minute).

Why are tachometers important in the automotive industry?

Tachometers help monitor engine speed, ensuring efficient fuel consumption and preventing potential engine damage due to over-revving.

How often should a tachometer be calibrated?

The frequency of calibration depends on the specific application and usage. Regular calibration ensures accurate and reliable readings.