The world of industrial machining is vast and varied, filled with numerous tools and machines that play pivotal roles. Among them, the Bridgeport milling machine stands out due to its significant impact on the industry. In this article, we will delve deep into what is a Bridgeport milling machine, its functions, and why it remains a popular choice among machining professionals.

History of the Bridgeport Milling Machine

To understand the present significance of the Bridgeport milling machine, it’s essential to know its history. Invented in the 1930s by Rudolph Bannow, Bridgeports manual mill became essential in countless machine shops due to its versatility and robustness.

Early Innovations

From its inception, the Bridgeport mill was known for its innovative designs. It brought several key features to the table, making it a revolutionary piece of machinery at that time.

Evolution Over The Years

Over the decades, the Bridgeport milling machine has evolved. Today, it incorporates advanced technology and features that make it indispensable for modern machining.

Features of a Bridgeport Milling Machine

Bridgeport milling machines are renowned for their versatile and durable design. Their features cater to various machining needs.

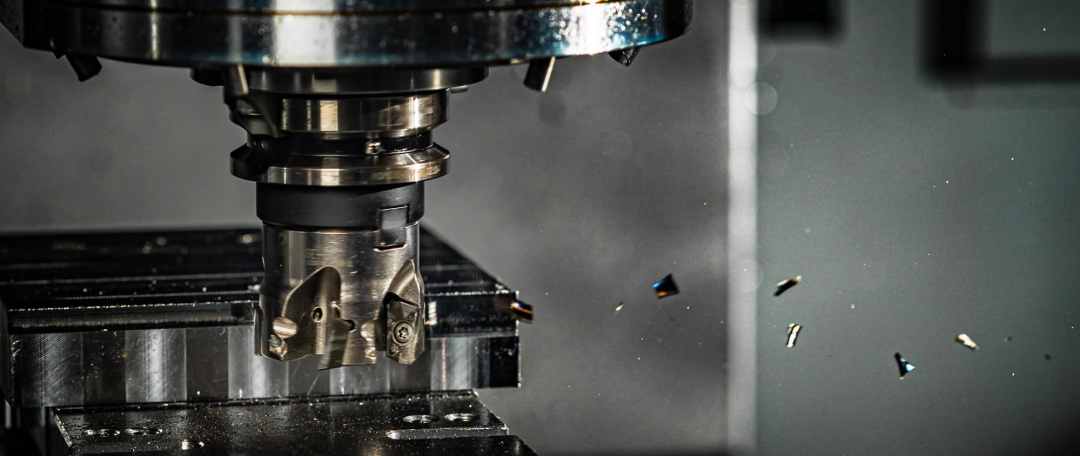

Precision and Accuracy

One of the biggest selling points of a Bridgeport milling machine is its precision. This machine ensures high accuracy in cutting and shaping metal, contributing to its popularity among machinists.

Adjustable Spindle

The spindle on a Bridgeport milling machine is adjustable. This allows for multiple forms of cutting, making the machine adaptable to different tasks.

Durable Construction

With its cast iron construction and robust design, the Bridgeport mill guarantees longevity and reliability under strenuous working conditions.

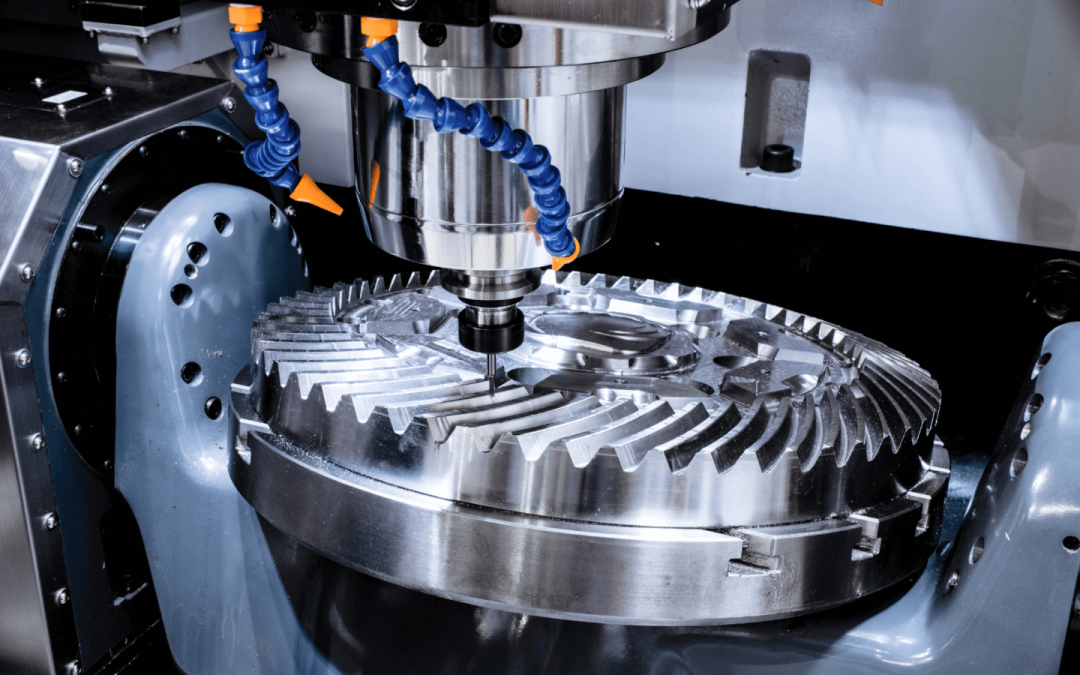

Types of Milling Operations

Bridgeport milling machines allow for various types of milling operations, making them incredibly versatile.

Face Milling

Face milling is one of the most common milling operations conducted using a Bridgeport machine. This operation involves cutting flat surfaces onto a workpiece.

Drilling and Boring

Aside from milling, the Bridgeport mill can also be used for drilling and boring holes with precision. This versatility adds to its utility in a machine shop.

Application in Industry

The uses of Bridgeport milling machines stretch far and wide, from custom fabrication to mass production settings.

Custom Fabrication

In custom fabrication, machinists require tools that offer versatility and precision. The Bridgeport mill provides both, making it a favorite among custom fabricators.

Mass Production

In mass production, efficiency and consistency are key. The Bridgeport milling machine delivers on these fronts, making it indispensable in large-scale manufacturing environments.

Advantages of Using a Bridgeport Milling Machine

There are several advantages to using a Bridgeport milling machine, which is why it’s a staple in many machine shops.

Ease of Use

Even for those new to machining, the Bridgeport mill is relatively easy to use. Its intuitive design simplifies the learning curve.

Versatility

One of the main advantages of a Bridgeport milling machine is its versatility. From drilling to cutting to shaping, this machine can handle a multitude of tasks.

Cost-Effectiveness

Although the initial investment may be high, the longevity and minimal maintenance requirements make the Bridgeport mill a cost-effective choice in the long run.

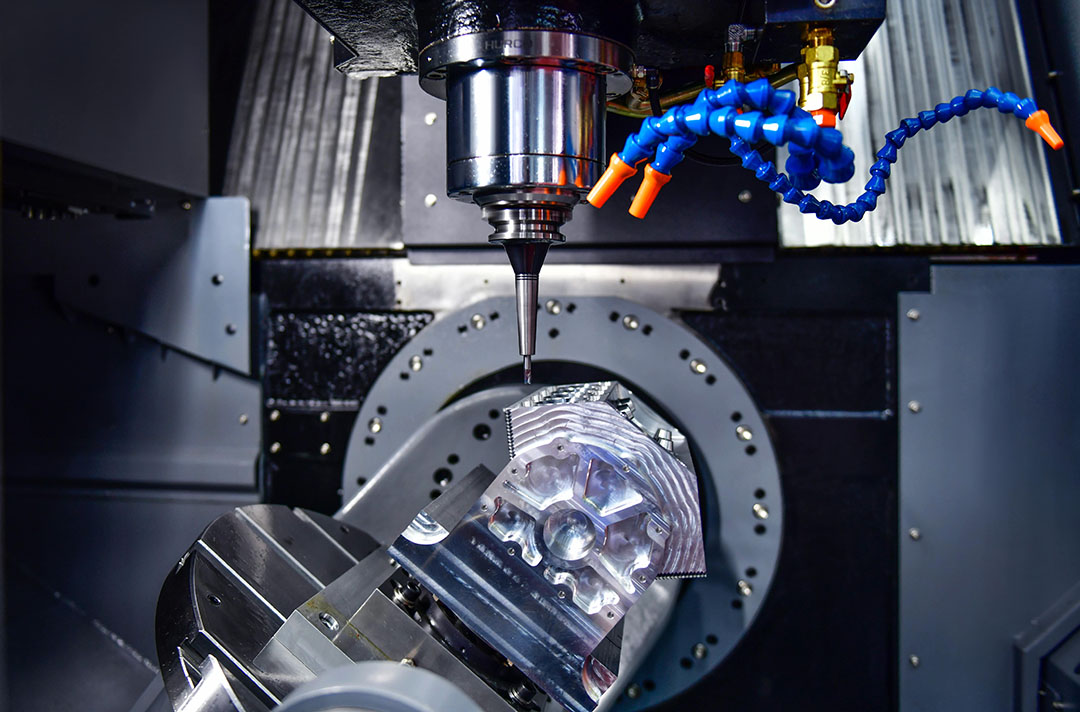

Bridgeport Milling Machine vs. CNC Machines

While both machines have their merits, several distinctions make each one suitable for different tasks.

Manual vs. Automated

A key difference between a Bridgeport milling machine and a CNC (Computer Numerical Control) machine is the level of automation. While the Bridgeport requires manual operation, CNC machines operate automatically based on pre-programmed sequences.

Complexity of Operations

CNC machines excel at performing complex operations with high precision. While a Bridgeport machine can handle intricate tasks, it may not match the accuracy and efficiency of a CNC machine for complicated jobs.

Modern Adaptations

As technology advances, so do the features of the Bridgeport milling machine.

Digital Readouts

Many modern Bridgeport mills come equipped with digital readouts, enhancing accuracy and making it easier for machinists to perform precise operations.

Computer Integration

Modern Bridgeport mills often include computer integration, allowing for increased functionality and more complex milling operations.

Maintenance and Care

Maintaining a Bridgeport milling machine is crucial for ensuring its longevity and functionality.

Regular Inspections

Regular inspections and maintenance routines are essential. Checking for wear and tear and ensuring all parts are well-lubricated can prolong the life of the machine.

Replacing Parts

Over time, certain parts may wear out and need replacement. Understanding how to recognize these signs and replace parts can save time and prevent bigger issues.

Training and Skill Development

Using a Bridgeport milling machine effectively requires skill and training.

Initial Training

Initial training is essential for anyone looking to use a Bridgeport mill. Understanding the machine’s operations and safety procedures is crucial.

Ongoing Skill Development

As you gain more experience, continuously developing your skills can open new machining possibilities and enhance your efficiency.

Why Choose a Bridgeport Milling Machine?

Should you invest in a Bridgeport milling machine? Understanding its benefits and applications can help you make an informed decision.

Trusted Brand

Bridgeport is a trusted brand in the machining industry, known for its reliability and quality. Investing in a Bridgeport milling machine means investing in a proven and trusted product.

Wide Range of Uses

From custom fabrication to mass production, Bridgeport milling machines find applications across various industries, making them a versatile choice.

Long-term Value

While the initial investment may be significant, the long-term value and durability of a Bridgeport mill make it a wise choice for any machine shop.

Conclusion

Bridgeport milling machines are a staple in the machining industry due to their versatility, durability, and efficiency. Understanding what is a Bridgeport milling machine and its various features can help you appreciate its importance in both custom and mass production settings.

For more in-depth information on milling machines, you can visit this external link.

FAQs

What is the primary use of a Bridgeport milling machine?

The primary use of a Bridgeport milling machine is to cut, shape, and drill metal or other materials with high precision.

Is a Bridgeport milling machine suitable for beginners?

Yes, its intuitive design makes it relatively easy for beginners to learn and use effectively.

How should I maintain my Bridgeport milling machine?

Regular inspections, proper lubrication, and timely replacement of worn-out parts are essential for maintaining your Bridgeport milling machine.

For more depth on similar topics, check out our articles on genetic analysis, semiconductor polishing, and advantages of CNC machines.