In modern manufacturing, the question that often arises is, What is a CNC milling machine? This Big Technology has revolutionized the industry with its precision and efficiency. From large-scale factories to small workshops, CNC milling machines are now a critical tool in the production arsenal, offering tremendous advantages over traditional machining processes. Delighted to share more about this approved technology and its significant benefits.

What is a CNC Milling Machine?

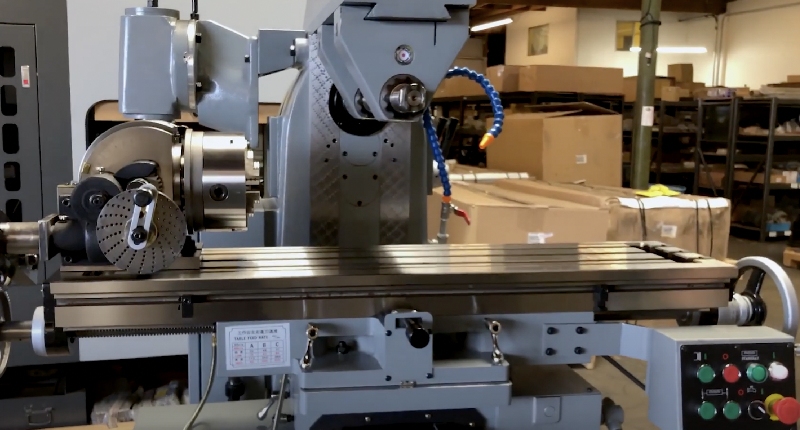

A CNC milling machine is a computer-controlled machine tool used for machining various materials such as metal, plastic, and wood. CNC stands for Computer Numerical Control, which means that the machine operates based on programmed instructions encoded into its computer. These machines are capable of creating intricate and precise parts with minimal human intervention, thus increasing productivity and reducing the risk of human error.

Mechanical Components of CNC Milling Machines

The main mechanical components of a CNC milling machine include the spindle, the work table, the column, and the control system. The spindle holds the cutting tool in place and rotates it at high speeds. The work table supports the material being worked on, while the column provides stability to the machine. The control system is the brain of the machine, executing the programmed instructions with high precision.

The Role of Software in CNC Milling

The role of software in CNC milling is crucial. CNC machines rely on Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to create and execute the designs. The CAD software is used to create the designs, while the CAM software generates the code that the machine will execute.

How CNC Milling Machines Work

Programming the Machine

The first step in using a CNC milling machine is to create a design using CAD software. Once the design is complete, the CAM software translates it into G-code, which is the language understood by the CNC machine. The G-code contains a series of instructions that tell the machine how to move, where to cut, and at what speed.

Setting Up the Machine

The next step is to set up the machine. This involves securing the material to be machined on the work table and installing the appropriate cutting tool in the spindle. The machine is then calibrated to ensure that it will operate accurately and precisely.

Executing the Job

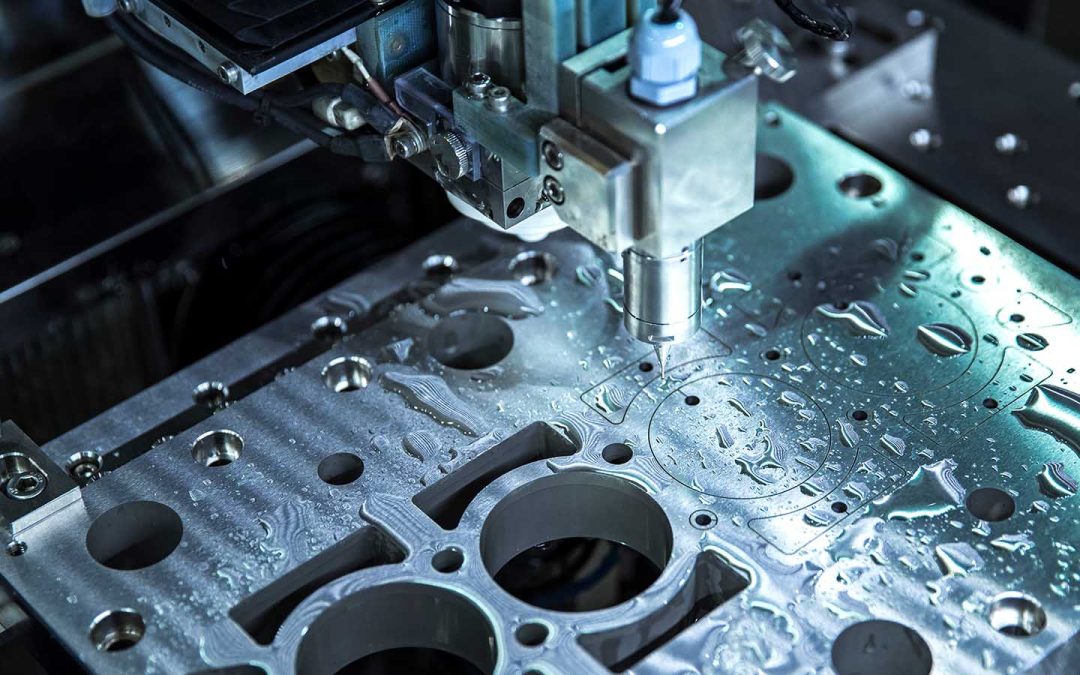

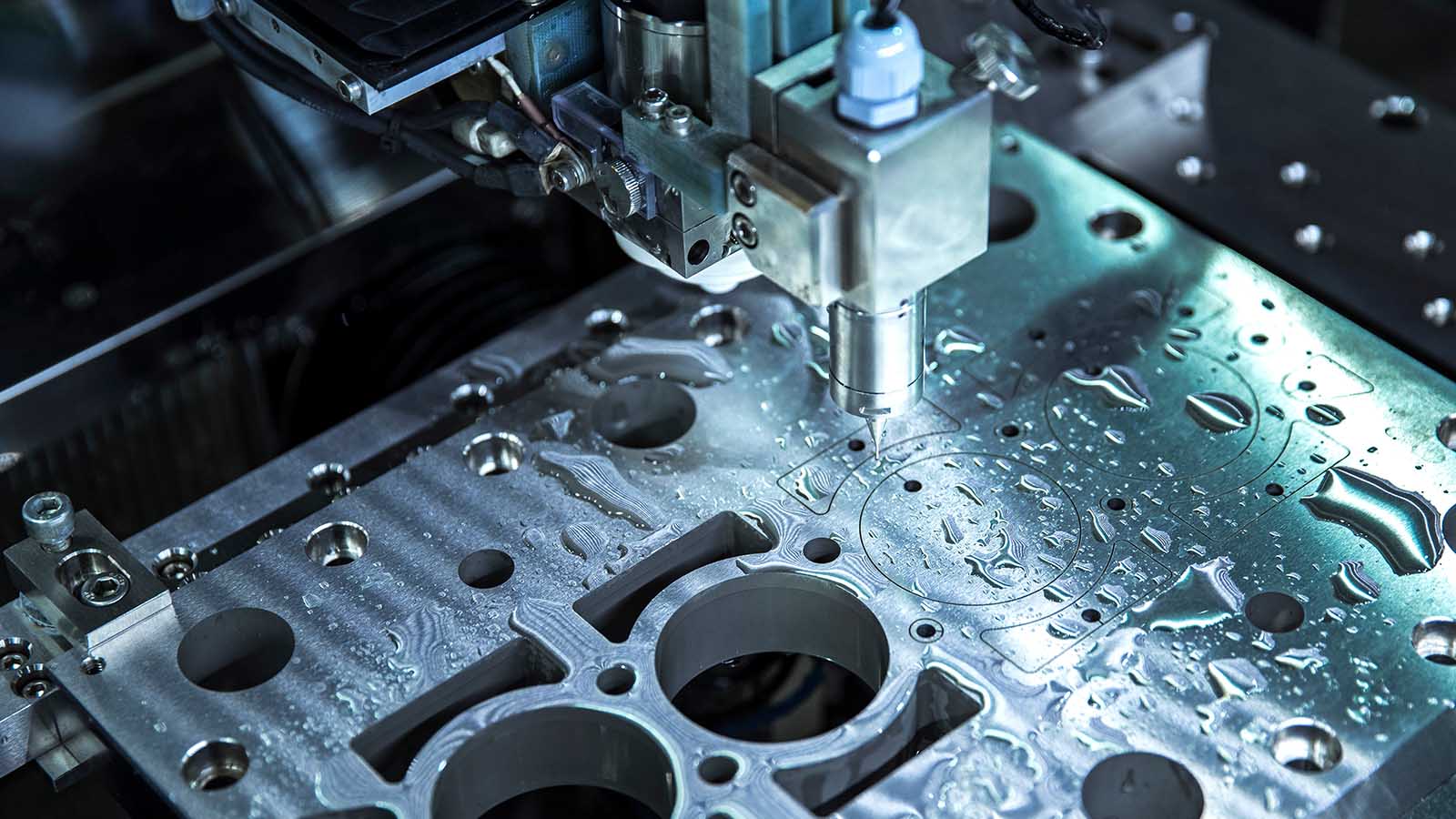

Once the machine is set up, it is ready to execute the job. The operator loads the G-code into the machine’s control system and starts the process. The machine then follows the instructions in the G-code to create the desired part. During this process, the machine makes numerous precise cuts, creating intricate designs and shapes with high accuracy.

Advantages of CNC Milling Machines

Precision and Accuracy

One of the main advantages of CNC milling machines is their precision and accuracy. These machines can create parts with extremely tight tolerances, which is crucial in industries such as aerospace and automotive where precision is paramount.

Increased Efficiency

CNC milling machines are also known for their efficiency. The ability to operate continuously with minimal supervision and the use of automated tool changers means that these machines can produce parts faster and more reliably than traditional machining methods.

Versatility

CNC milling machines are highly versatile and can be used to machine a wide variety of materials, including metals, plastics, and composites. They can also create complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

Types of CNC Milling Machines

Horizontal Milling Machines

Horizontal milling machines have a horizontally oriented spindle and are typically used for working on larger surfaces. They are ideal for creating slots, grooves, and other complex shapes.

Vertical Milling Machines

Vertical milling machines have a vertically oriented spindle and are typically used for machining smaller parts. They are more versatile than horizontal milling machines and are capable of performing a wide variety of machining operations.

Universal Milling Machines

Universal milling machines are capable of performing both horizontal and vertical milling operations. They offer greater flexibility and can be used for a wide range of machining tasks.

Applications of CNC Milling Machines

Aerospace Industry

In the aerospace industry, the high precision and accuracy of CNC milling machines are essential for creating complex parts such as engine components and airframe structures.

Automotive Industry

CNC milling machines are also widely used in the automotive industry for creating parts such as engine blocks, transmission components, and suspension parts.

Medical Device Manufacturing

In the medical device industry, CNC milling machines are used to create precise and intricate components for devices such as implants and surgical instruments.

Challenges and Limitations of CNC Milling Machines

Initial Cost and Maintenance

One of the main challenges of CNC milling machines is their initial cost. These machines can be quite expensive to purchase and require ongoing maintenance to ensure that they operate efficiently and accurately.

Skill Requirements

Although CNC milling machines automate many aspects of the machining process, skilled operators are still required to program and set up the machines. Proper training and experience are essential for achieving the desired results.

The Future of CNC Milling Machines

The future of CNC milling machines looks bright, with ongoing advancements in technology set to further enhance their capabilities. Developments in artificial intelligence and machine learning are expected to lead to even greater levels of automation and efficiency. Additionally, advancements in materials science will enable these machines to work with an even wider range of materials.

Conclusion

In conclusion, What is a CNC milling machine? It is a powerful and versatile tool that has transformed modern manufacturing. With their precision, efficiency, and versatility, CNC milling machines have become indispensable in a wide range of industries. As technology continues to advance, these machines are set to become even more capable, further driving innovation and productivity.

Internal Links

speed genetic

wafer polishing

semiconductor inspection

basic manual lathes

machines over lathes

FAQ

What is the difference between a CNC milling machine and a CNC lathe?

A CNC milling machine uses a rotary cutting tool to remove material from a workpiece, while a CNC lathe uses a stationary cutting tool to shape a rotating workpiece.

What materials can be machined using a CNC milling machine?

CNC milling machines can machine a wide variety of materials, including metals, plastics, and composites.

Do CNC milling machines require skilled operators?

Yes, skilled operators are required to program, set up, and maintain CNC milling machines.