In the world of machining and manufacturing, understanding what is a horizontal milling machine can significantly elevate your knowledge base. This article delves deep into the concept, components, and advantages of horizontal milling machines, providing a comprehensive guide for industry QA professionals and enthusiasts alike.

What is a Horizontal Milling Machine?

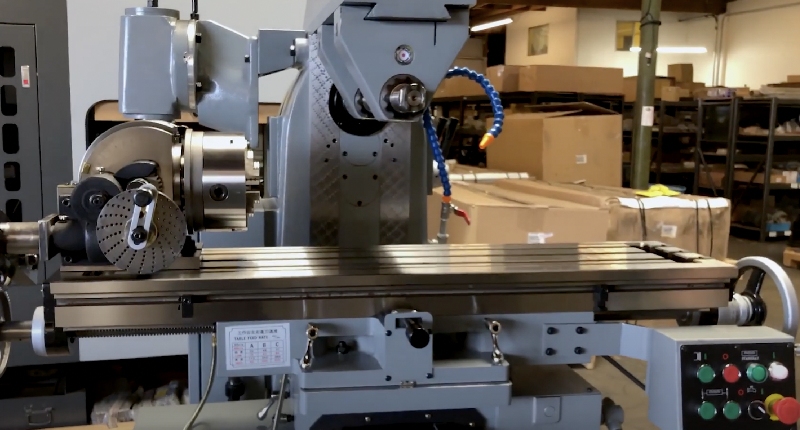

A horizontal milling machine is a type of machine tool with a horizontally oriented spindle. Unlike vertical milling machines, the cutting tool on a horizontal mill lies parallel to the worktable. In this article, we will explore the various aspects of this technology, including its components, working principles, applications, and advantages.

History and Evolution

Early Developments

The concept of milling machines has evolved over centuries. The first horizontal milling machines were rudimentary, requiring manual operations. These early machines laid the groundwork for the sophisticated mills we see today.

Learn more about the history and evolution of milling machines to understand how they shaped the modern manufacturing landscape [here](https://www.engineeringarticles.org/milling-machine-definition-process-types/#google_vignette).

Technological Advancements

With the advent of the Industrial Revolution, horizontal milling machines saw significant improvements. Features like automated feeds, enhanced precision, and the integration of Computer Numerical Control (CNC) have made these machines indispensable in modern manufacturing.

Components of a Horizontal Milling Machine

Spindle

The spindle is the core component that holds and drives the cutting tool. In horizontal mills, the spindle is horizontally oriented, allowing for more versatile machining.

Worktable

The worktable is where the material is clamped in place. It can move in several directions, providing flexibility in machining operations.

Arbor

The arbor is a cylindrical shaft that supports the cutting tool. It is attached to the spindle and holds the tool in place during operations.

Cutters

Horizontal mills use various types of cutters, including side and face mills, slot drills, and thread mills. Each has a specific application, contributing to the machine’s versatility.

Working Principles

Material Removal

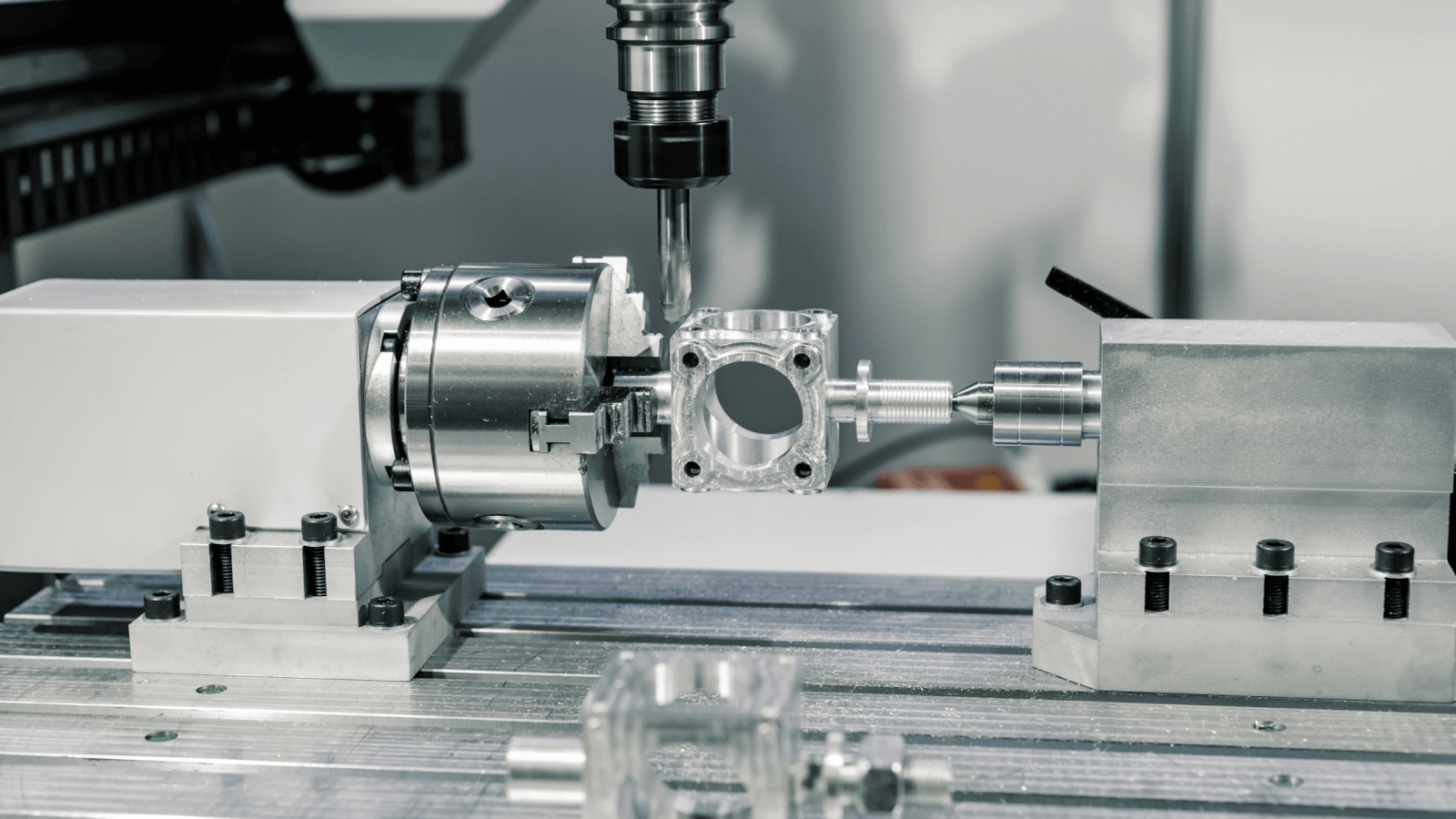

The primary function of a horizontal milling machine is material removal. The cutting tool rotates as the worktable moves, allowing for precise material removal.

Multiple Axis Control

Modern horizontal mills often feature multiple axes, enabling complex machining operations. This multi-axis control allows for intricate designs and improved accuracy.

Applications in Various Industries

Automotive Industry

Horizontal milling machines are widely used in the automotive industry for machining engine blocks, transmission cases, and other essential components.

Aerospace Industry

In the aerospace industry, these machines are crucial for manufacturing intricate parts like turbine blades and structural components.

General Manufacturing

From custom parts to batch production, horizontal milling machines find applications across various general manufacturing sectors.

Advantages of Using Horizontal Milling Machines

Increased Production Rates

The parallel orientation of the spindle allows for faster production rates compared to vertical mills.

Versatility

The ability to perform multiple operations with one setup makes horizontal mills highly versatile.

Challenges and Limitations

Space and Cost

Horizontal milling machines are often larger and more expensive than their vertical counterparts, making them less accessible for smaller operations.

Complex Setup

The setup process for these machines can be complex, requiring skilled operators for optimal performance.

Maintenance and Best Practices

Regular Inspection

Regular inspection and maintenance are crucial for prolonging the life of your horizontal milling machine. Check components like the spindle, arbor, and worktable for wear and tear.

Lubrication

Proper lubrication is essential for smooth operation and to prevent overheating and damage.

Calibration

Periodic calibration ensures that the machine maintains its precision and accuracy over time.

Future Trends and Innovations

Automation

The integration of automation and robotics is set to revolutionize horizontal milling, making operations faster and more efficient.

Smart Technology

Advancements in smart technology, such as IoT and machine learning, are expected to further enhance the capabilities of horizontal milling machines.

FAQs

What materials can be machined using a horizontal milling machine?

Horizontal milling machines are versatile and can handle a variety of materials, including metals, plastics, and composites.

How does a horizontal milling machine differ from a vertical milling machine?

The primary difference lies in the orientation of the spindle. Horizontal mills have a spindle that lies parallel to the worktable, while vertical mills have a spindle that is perpendicular.

Is it necessary to have a skilled operator for a horizontal milling machine?

Yes, skilled operators are essential for the optimal performance of horizontal milling machines due to their complex setup and operation.

Conclusion

Understanding what is a horizontal milling machine is crucial for anyone involved in the machining and manufacturing industries. These machines offer a range of benefits, from increased production rates to versatility, making them an invaluable asset. As technology advances, the capabilities of horizontal milling machines are set to expand, offering even more opportunities for innovation and efficiency.

For more detailed information on various types of milling machines, you can visit this link.