A milling machine is a vital tool in the manufacturing industry, known for its incredible efficiency and versatility. It plays a significant role in the production of various complex parts and components used across different sectors. But what exactly is a milling machine, and why is it so essential to modern manufacturing processes?

The Basics of Milling Machines

The Definition

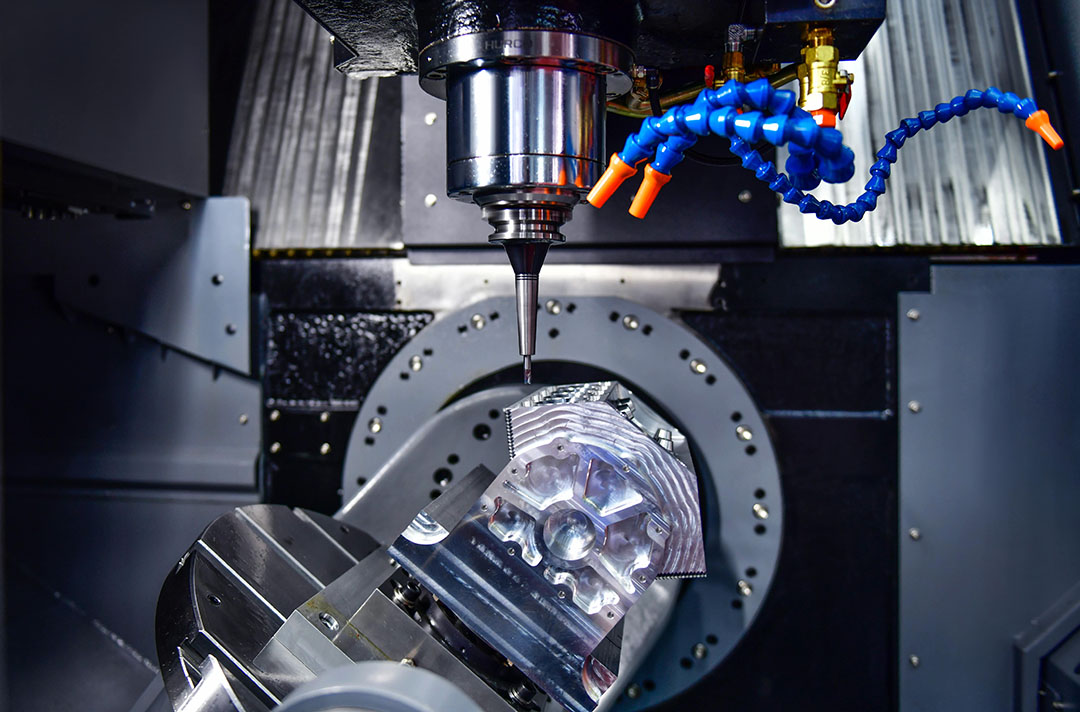

A milling machine is a type of machine tool that uses rotary cutters to remove material from a workpiece. It can perform various operations like cutting, pressing, and shaping to produce parts with precise geometries. These machines are used for tasks that require high accuracy and complex designs.

Primary Components

Milling machines consist of several components, each playing a crucial role in its functionality. The primary elements include:

- Spindle: The rotating component that holds and drives the cutting tool.

- Table: The surface on which the workpiece is placed and moved during the process.

- Knee: The adjustable vertical component that supports the table.

- Column: The structure that supports the spindle and other machine parts.

- Base: The foundation of the machine, providing stability.

Types of Milling Machines

Vertical Milling Machines

In a vertical milling machine, the spindle is oriented vertically. It is commonly used for tasks requiring precision and intricate detailing. See more details on vertical milling machines.

Horizontal Milling Machines

These machines have a horizontally oriented spindle, ideal for heavy cutting operations. They provide high efficiency and versatility, especially in large-scale production.

CNC Milling Machines

Computer Numerical Control (CNC) milling machines are automated and highly precise. They are utilized for producing complex and identical parts in large quantities. CNC technology enhances operational efficiency and reduces human error.

Universal Milling Machines

These versatile machines can perform both horizontal and vertical milling operations. They are highly adaptable and are a favorite among manufacturers looking for flexibility.

How Milling Machines Work

Milling machines operate by using rotary cutters to remove material from a workpiece. The process involves mounting the workpiece on the table and securing it in place, while the spindle rotates the cutting tool at high speed. The table can move in different directions, allowing the cutter to shape the workpiece into the desired form.

The Milling Process

The milling process includes several steps, starting with planning the operation, selecting the appropriate cutting tool, and adjusting the machine settings. Once the setup is complete, the actual milling takes place, followed by finishing and inspection to ensure the desired specifications are met.

Types of Cutting Tools

Milling machines use a variety of cutting tools, including end mills, face mills, and ball cutters. Each tool serves a specific purpose and is chosen based on the requirements of the operation.

Advantages of Using Milling Machines

Milling machines offer several advantages, making them indispensable in the manufacturing industry. Some of the key benefits include:

- High Precision: Milling machines provide accurate and precise results, essential for producing components with tight tolerances.

- Versatility: These machines can perform a wide range of operations, including cutting, drilling, and shaping.

- Efficiency: Modern milling machines, especially CNC variants, offer high-speed operations, reducing production time.

- Cost-Effectiveness: Milling machines can produce complex parts at a lower cost than manual methods.

Common Applications of Milling Machines

Automotive Industry

In the automotive industry, milling machines are used to produce various engine components, transmission parts, and other critical elements. Their precision and efficiency make them ideal for mass production.

Aerospace Industry

The aerospace industry relies on milling machines to manufacture parts with complex geometries and high precision. Components like turbine blades, aircraft frames, and other critical parts are often produced using these machines.

Medical Device Manufacturing

Milling machines play a crucial role in producing medical devices, such as implants, surgical instruments, and prosthetics. Their precision ensures that these devices meet stringent quality standards.

Electronics Industry

In the electronics industry, milling machines are used to create intricate circuit boards and other components. Their ability to work with small and delicate parts makes them essential for this sector.

Energy Sector

The energy sector utilizes milling machines to produce components for power generation equipment, including turbines, generators, and other critical parts. Their durability and efficiency make them ideal for this demanding industry.

Choosing the Right Milling Machine

Selecting the right milling machine depends on several factors, including the nature of the work, the required precision, and the available budget. It’s essential to consider these aspects to ensure the machine meets the specific needs of the operation.

Factors to Consider

When choosing a milling machine, consider the following factors:

- Size and Capacity: The machine’s size and capacity should match the requirements of the tasks it will perform.

- Precision: Ensure the machine can achieve the necessary level of precision for the work.

- Automation: Decide whether a manual, semi-automatic, or fully automated machine is needed.

- Budget: Consider the cost of the machine and its long-term operational expenses.

Maintenance and Care

Proper maintenance is crucial for the longevity and efficiency of a milling machine. Regular inspections, lubrication, and timely repairs ensure the machine operates smoothly and produces high-quality results.

Operator Training

Training operators on the correct use and maintenance of milling machines is essential. Skilled operators can significantly enhance the machine’s performance and ensure safe and efficient operations.

Future Trends in Milling Machine Technology

Advancements in CNC Technology

As CNC technology continues to evolve, milling machines are becoming more sophisticated and capable. Features like advanced software, real-time monitoring, and improved automation are driving efficiency and precision to new heights.

Integration with IoT

The integration of milling machines with the Internet of Things (IoT) is enabling smarter operations. IoT connectivity allows for real-time data collection, remote monitoring, and predictive maintenance, enhancing overall productivity.

Environmental Considerations

Environmental sustainability is becoming a priority in manufacturing. Milling machines are being designed to reduce energy consumption, minimize waste, and operate with eco-friendly lubricants and coolants.

FAQ

1. Why are milling machines essential in manufacturing?

Milling machines offer high precision, versatility, and efficiency, making them indispensable for producing complex and accurate parts used in various industries.

2. What are the types of milling machines?

There are several types of milling machines, including vertical, horizontal, CNC, and universal milling machines, each designed for specific tasks and requirements.

3. How do I choose the right milling machine?

When choosing a milling machine, consider factors such as size and capacity, precision, automation level, and budget to ensure it meets your specific needs.

4. What are the common applications of milling machines?

Milling machines are commonly used in automotive, aerospace, medical device manufacturing, electronics, and the energy sector for producing various components and parts.

For more in-depth information on milling machines, you can visit Engineering Articles.