What is a radial drill press? Many industry professionals, ranging from engineers to QA specialists, often encounter this term. A radial drill press is a versatile and essential tool in the world of manufacturing and machining. Its design and functionality make it an indispensable asset for various industries. Understanding what a radial drill press is and how it operates can significantly enhance the efficiency of any project or production line.

What Exactly Is a Radial Drill Press?

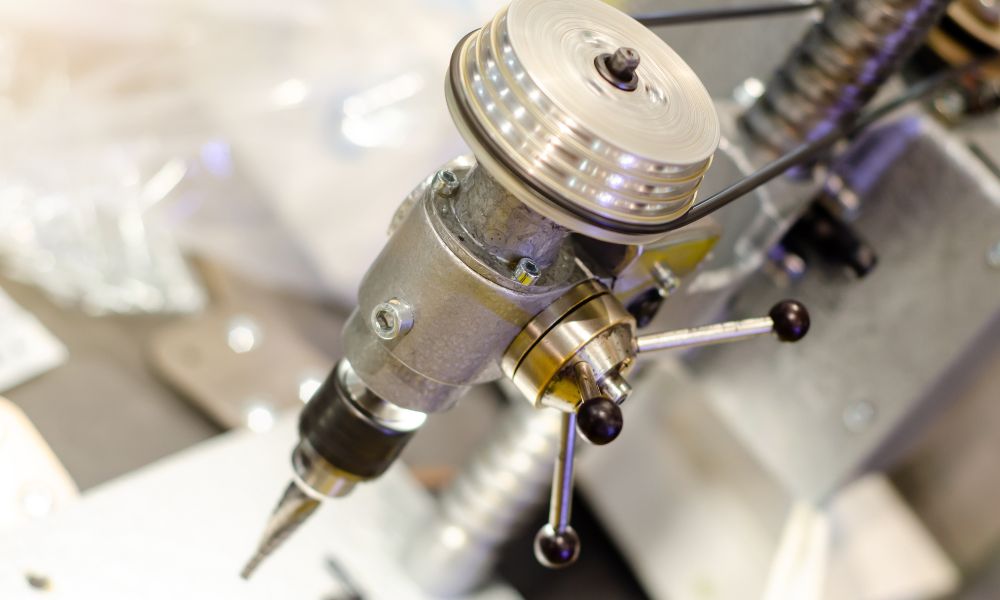

A radial drill press is a machine used for drilling holes in metal, wood, or other solid materials. What sets it apart from standard drill presses is its unique arm, known as a radial arm, that extends out from the column, allowing for a higher degree of flexibility and precision. This design feature enables the user to move the drill head along the arm, facilitating the drilling of holes at different angles and distances from the column without having to reposition the workpiece.

How Does a Radial Drill Press Work?

The Basic Components

A radial drill press generally consists of the following main components:

- Base: The base supports the entire machine and is usually bolted to the floor to ensure stability.

- Column: The vertical pillar that supports the radial arm and the drill head.

- Radial Arm: The horizontal arm that can extend and retract, allowing the drill head to move.

- Drill Head: Holds the motor and the drill bit, facilitating the drilling operation.

- Table: The platform on which the workpiece is placed.

Types of Radial Drill Presses

Manual Radial Drill Press

Manual radial drill presses are operated by hand, requiring the user to manually adjust the radial arm and apply pressure. These are typically used for smaller, less complex projects.

Semi-Automatic Radial Drill Press

Semi-automatic models offer a blend of manual operation and automated features, enabling greater control while reducing the physical effort required.

Fully Automatic Radial Drill Press

Fully automatic radial drill presses are equipped with advanced features such as programmable controls and automated drilling cycles, making them suitable for high-volume, complex drilling tasks.

Applications and Uses

The radial drill press finds extensive applications in various industries:

- Automotive Industry: For drilling holes in engine blocks, chassis components, and other parts.

- Construction: Used for drilling large holes in steel beams and other structural elements.

- Manufacturing: Essential for the production of machinery parts and equipment.

- Metalworking: Enables precise drilling in metal fabrication processes.

Advantages of Using a Radial Drill Press

There are several key advantages to using a radial drill press:

- Flexibility and Versatility: The radial arm allows for a wide range of motion, enabling drilling at various angles and positions.

- Precision: Enhanced accuracy reduces the margin for error, ensuring high-quality results.

- Efficiency: Suitable for both small-scale and large-scale projects, improving overall productivity.

Maintenance and Care

Proper maintenance is crucial for ensuring the longevity and optimal performance of a radial drill press. Regular cleaning, lubrication of moving parts, and inspection for wear and tear are essential practices.

FAQs

1. What materials can be drilled using a radial drill press?

The radial drill press can drill through a variety of materials, including metal, wood, and plastics.

2. How does a radial drill press differ from a standard drill press?

The primary difference is the radial arm, which provides greater flexibility and precision in drilling operations.

3. Are radial drill presses suitable for beginners?

While they offer advanced features, radial drill presses can also be used by beginners with proper training and safety precautions.

Conclusion

Understanding what is a radial drill press is invaluable for industry QA professionals and anyone involved in machining or manufacturing. Its tremendous technology and big benefits make it an excellent investment for improving the efficiency and precision of various drilling tasks.

More about drill pressesEvent DetectionPaint InspectionGenetic AnalysisWafer PolishingManufacturing Inspection