The question what is a vertical milling machine often arises among industry professionals. This article delves into the intricacies of vertical milling machines, providing detailed insights that are sure to leave you delighted with your newfound knowledge.

Understanding Milling Machines

Vertical vs. Horizontal Milling Machines

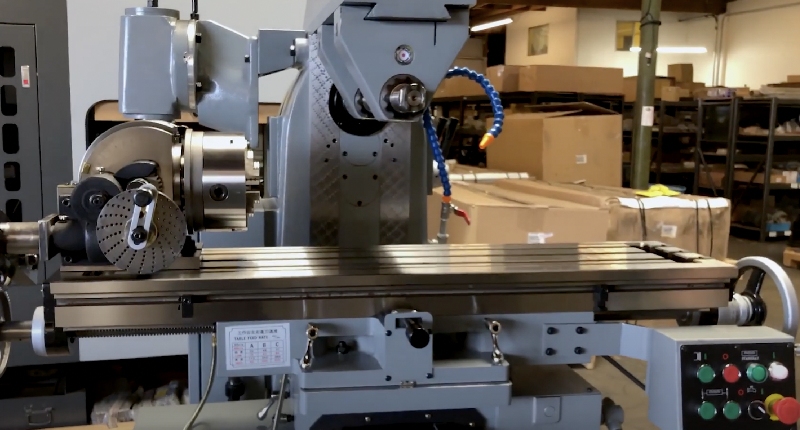

Milling machines come in various forms, with vertical and horizontal being the most common. Understanding the differences between these two types is crucial for selecting the right equipment for your needs.

Parts of a Vertical Milling Machine

A vertical milling machine consists of numerous key components, each playing a vital role in the overall machining process. Here, we’ll break down the essential parts and their functions.

How Does a Vertical Milling Machine Work?

The Milling Process

The working principle of a vertical milling machine revolves around the movement of the workpiece and the tool. The specific movements and operations can significantly affect the final output.

Types of Milling Operations

Vertical milling machines are capable of performing a wide range of operations. From simple drilling projects to more complex tasks like gear cutting, these machines are designed for versatility.

Advantages of Vertical Milling Machines

Superior Precision and Accuracy

One of the main advantages of vertical milling machines is their ability to produce highly precise and accurate components. This makes them ideal for industries requiring stringent quality standards.

Space-Efficient Design

Another significant advantage is the space-efficient design of vertical milling machines. Their compact footprint allows for easier integration into existing shop floors.

Applications of Vertical Milling Machines

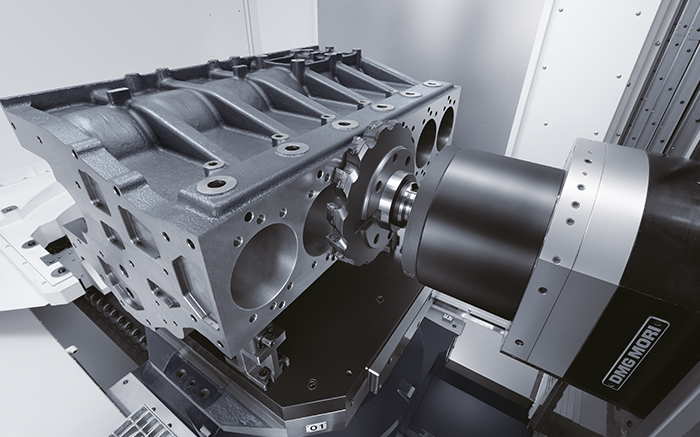

Automotive Industry

The automotive industry frequently utilizes vertical milling machines for manufacturing various components and parts, thanks to their precision and reliability.

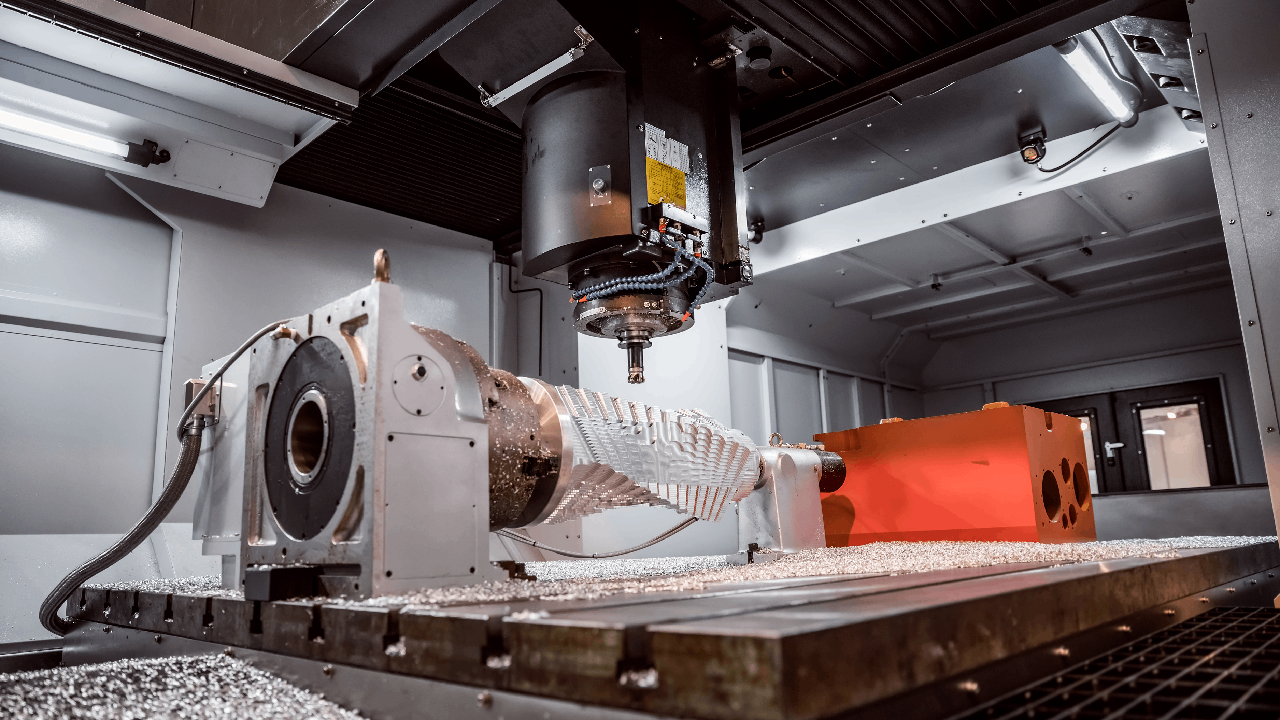

Aerospace Industry

Due to the demanding requirements of aerospace components, vertical milling machines are often the go-to equipment for machining these high-precision parts.

Vertical Milling Machine Maintenance

Routine Maintenance

Regular maintenance of vertical milling machines is essential for ensuring their longevity and consistent performance. Simple measures like lubrication and cleaning can go a long way.

Troubleshooting Common Issues

Even the most well-maintained machines can face issues. Knowing how to troubleshoot common problems can save time and resources.

Future of Vertical Milling Machines

Technological Advancements

As technology continues to evolve, so do vertical milling machines. Advanced features and capabilities are being integrated to enhance their performance and efficiency.

Market Trends

The market for vertical milling machines is expected to grow, driven by increasing demand from various industries. Staying updated on market trends can provide a competitive edge.

Conclusion

Understanding what is a vertical milling machine is crucial for industry QA professionals. These machines are versatile, precise, and essential for various industrial applications. By staying informed about their operation, maintenance, and market trends, you can make better decisions and achieve tremendous success in your projects.

FAQs

What are the key components of a vertical milling machine?

The key components of a vertical milling machine include the base, column, spindle, and table.

How often should I perform maintenance on a vertical milling machine?

Regular maintenance, including lubrication and cleaning, should be performed frequently to ensure optimal performance.

What industries benefit the most from vertical milling machines?

Industries such as automotive, aerospace, and manufacturing benefit significantly from the precision and versatility of vertical milling machines.

For more details, you can visit this guide or explore types of milling machines.

For more insights on industrial machinery, check out our articles on high-speed genetic analysis, semiconductor wafer polishing, and advantages of CNC machines.