When delving into the world of milling machines, the term arbor is a fundamental concept that Industry QA Professionals must be well-acquainted with. But what is arbor in milling machine? This question often puzzles both newcomers and seasoned professionals in the machining field. In this article, we will explore this topic in-depth to offer a comprehensive understanding of arbors and their vital role in milling machines.

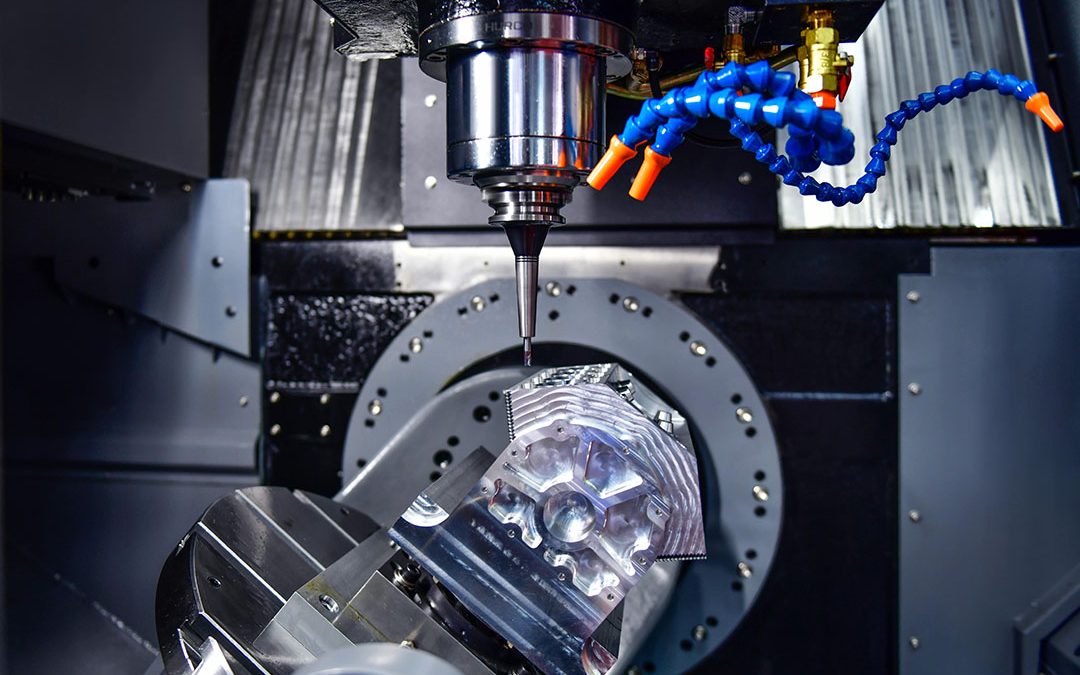

The term arbor is used to denote a spindle or shaft that holds or guides a cutting tool or machine component. In milling machines, the arbor serves as the axis of rotation for the cutting tool. Understanding this core component not only enhances your technical competency but also significantly contributes to optimizing machining processes.

Importance of Arbor in Milling Machines

Arbors play a crucial role in the functioning of milling machines. They ensure stable and precise positioning of the cutting tool, which directly impacts the quality of the machining process. By understanding what is arbor in milling machine, operators can better manage tool wear, enhance cutting efficiency, and achieve improved surface finishes.

Types of Arbors

Milling Machine Arbor

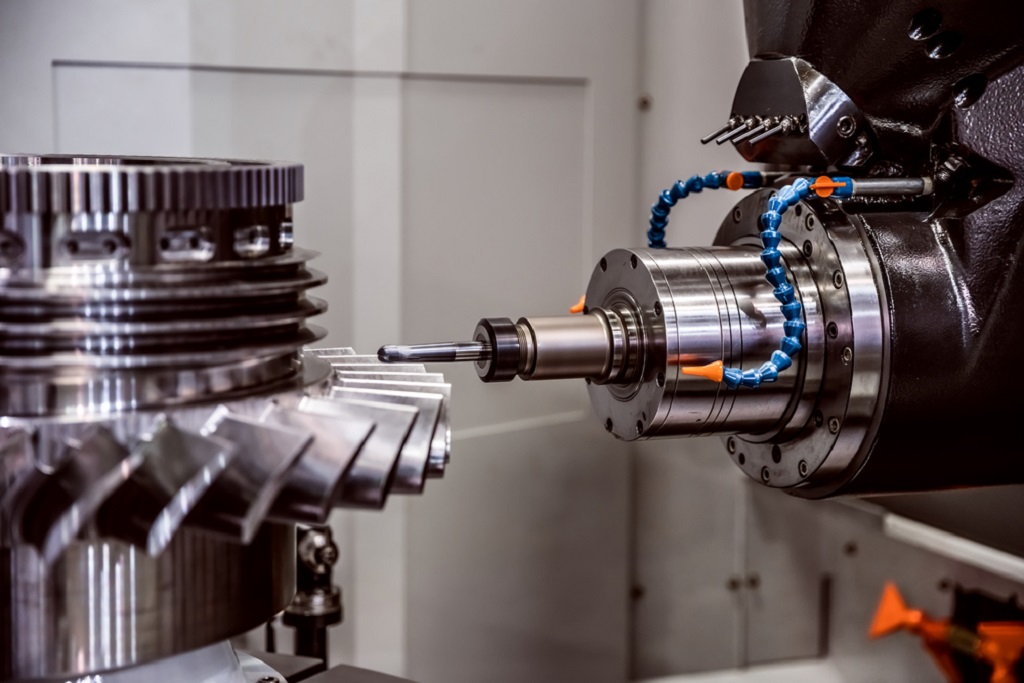

A milling machine arbor is specifically designed to hold milling cutters securely during operation. Common types include the stub arbor, shell end mill arbor, and slitting saw arbor.

Drill Arbor

Drill arbors, or chucks, are used to hold drill bits.

Functions and Uses

The primary function of an arbor in a milling machine is to hold the cutting tool in place. This ensures high rotational accuracy and minimizes tool deflection, which is essential for maintaining precision during machining processes.

Components of an Arbor

An arbor comprises several key components, including the taper, spacer, drawbar, and arbor support. Each component plays a vital role in ensuring the arbor’s stability and effectiveness during machining operations.

Arbor Installation

Proper installation is crucial for the effective functioning of an arbor. Simple steps involve cleaning the components, aligning the arbor spindle, and securing it with a drawbar.

Maintaining an Arbor

Regular maintenance of the arbor is essential to prolong its lifespan and ensure consistent performance. This includes routine checks for wear and tear, proper lubrication, and cleaning.

Troubleshooting Common Issues

Common issues include tool chatter, excessive wear, and misalignment. Effective troubleshooting involves routine inspections, re-calibration, and replacing worn-out components.

Choosing the Right Arbor

Selecting the right arbor depends on several factors, including the type of milling machine, the nature of the cutting operation, and the material being machined.

Modern Technology and Arbors

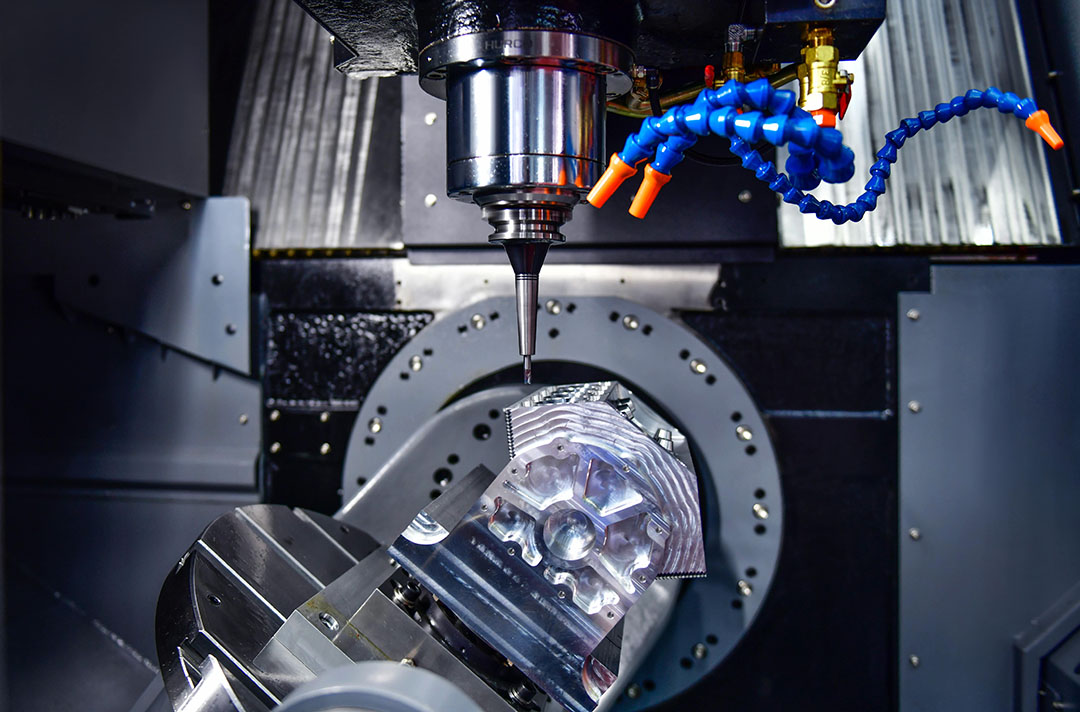

Arbor technology has seen tremendous advancements. Today’s arbors are designed for higher precision, durability, and compatibility with advanced milling machines, significantly enhancing overall efficiency.

Safety Precautions

Safety is paramount when dealing with milling machines. Operators must adhere to standard safety practices, including using personal protective equipment (PPE) and ensuring the arbor is properly secured before operation.

Industry Standards

Industry standards for arbors ensure that they are manufactured to meet specific requirements for performance and safety. Adhering to these standards is essential for achieving reliable and consistent machining results.

Advantages of Using Arbors

Using arbors in milling machines offers several advantages, such as improved precision, reduced tool deflection, and enhanced process stability. These benefits contribute to higher quality and efficiency in machining operations.

To learn more about Advanced Stroboscopic Event Detection in Semiconductor Wafer Polishing, visit this page.

Applications in Different Industries

Arbors are utilized in various industries, including automotive, aerospace, and manufacturing. Their versatility and effectiveness make them indispensable components in many machining processes.

For details on High-Speed Paint and Coating Application Inspection, click here.

Future Trends

The future of arbors in milling machines looks promising with continuous advancements in technology. Emerging trends include the integration of smart sensors and automated adjustment features, further enhancing their precision and ease of use.

For more insights, check out High-Speed Genetic Analysis and Sequencing Monitoring here.

Conclusion

Understanding what is arbor in milling machine is crucial for professionals in the machining industry. The arbor plays a fundamental role in machining processes, ensuring precision, stability, and efficiency. As technology continues to evolve, we can expect further advancements in arbor design and functionality, driving the future of machining to new heights.

FAQs

What materials are commonly used to manufacture arbors?

Arbors are typically made from high-strength materials such as high-speed steel (HSS) or carbide to withstand the intense conditions of milling operations.

How do I know if my arbor needs replacement?

Signs of needing replacement include visible wear, tool chatter, and significant deflection during machining processes. Regular inspections can help identify these issues early.

Is it possible to use a drill arbor in a milling machine?

While drill arbors are designed for drilling operations, they are not typically suitable for milling. Each type of arbor is specifically designed for its intended application to ensure optimal performance and safety.