When it comes to the world of milling machines, there’s one component that stands out above the rest: the spindle. So, what is spindle in milling machine? Let’s delve into this topic and uncover its importance in the milling process.

The spindle is a key component in any milling machine. It serves as the core mechanism that holds and rotates the cutting tool. This allows precise material removal during machining tasks.

The Role of the Spindle

Spindles in milling machines are pivotal for the overall performance and precision of the machining process. They facilitate the rotation of cutting tools, enabling operations such as drilling, cutting, and shaping various materials.

Spindle Components

A typical spindle assembly consists of multiple key components:

- Spindle Shaft: The main axis that holds the cutting tool.

- Bearings: Ensure smooth rotation and support.

- Motor: Powers the spindle’s rotation.

- Housing: Encases the spindle and other components.

Types of Spindles

There are several types of spindles, each designed for specific applications:

Vertical Spindles

Used mainly in vertical milling machines. Ideal for tasks that require high precision.

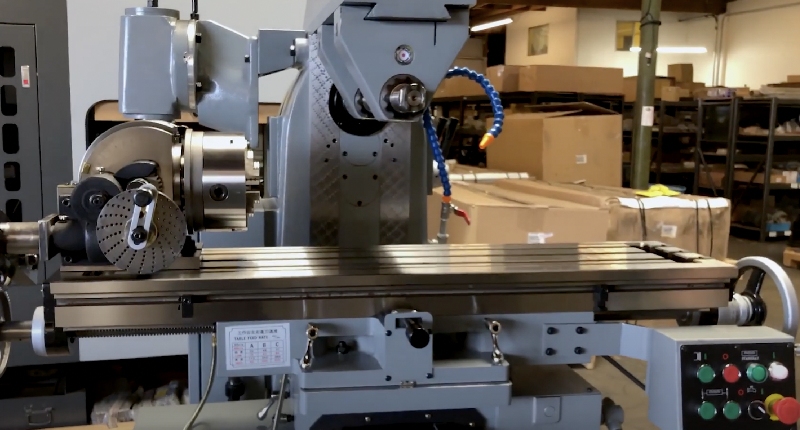

Horizontal Spindles

Found in horizontal milling machines, these are perfect for heavy-duty operations.

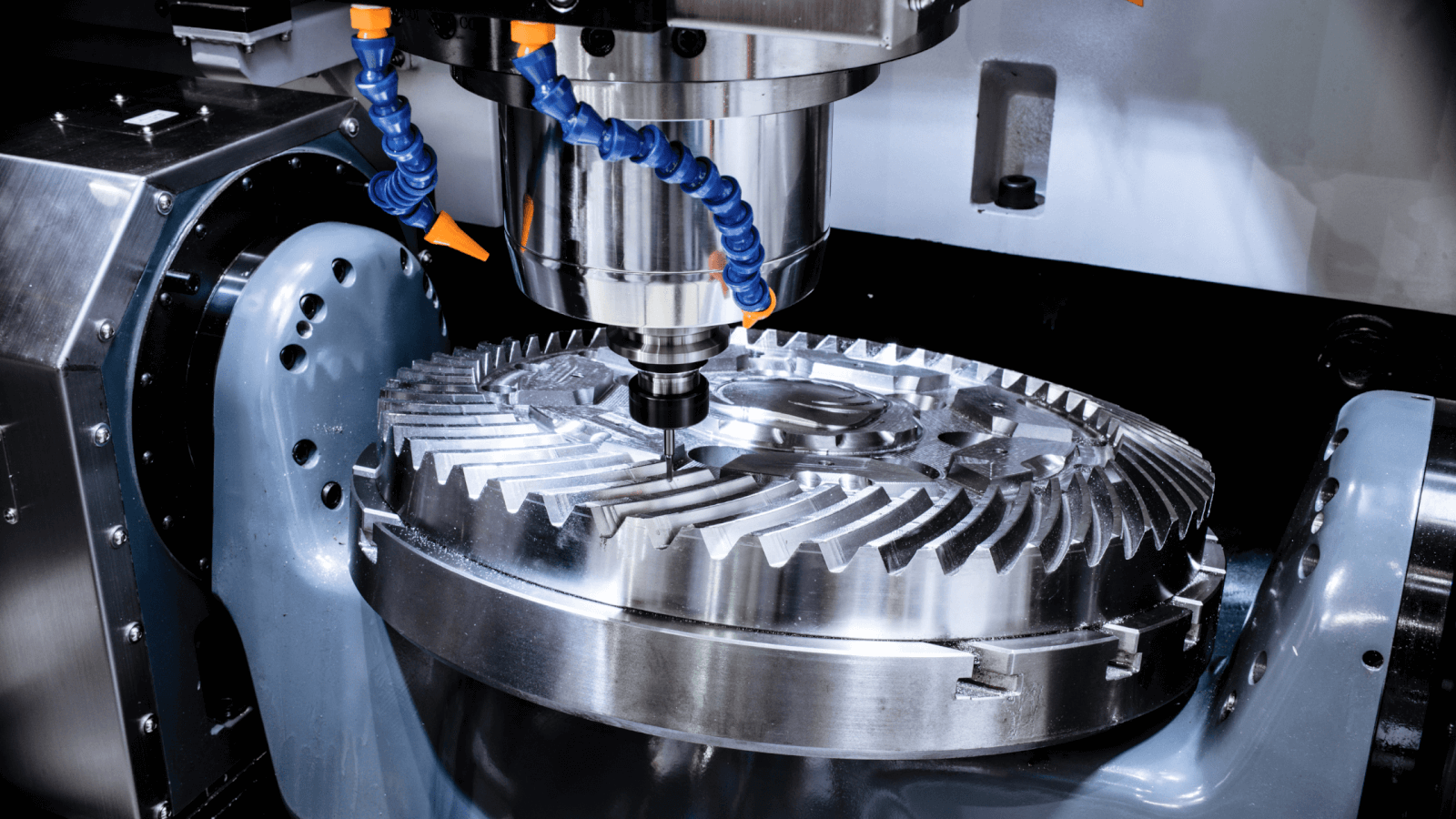

CNC Spindles

Integrated into CNC machines, offering advanced automation and precision.

Spindle Speed and Control

The speed and control of the spindle are crucial for achieving the desired machining results. Modern machines offer variable speed controls to accommodate different materials and operations.

Maintenance and Care

Proper maintenance of the spindle is essential for longevity and performance. Regular lubrication, alignment checks, and timely replacement of worn-out components can significantly enhance its lifespan.

Innovations in Spindle Technology

Recent advancements in spindle technology have led to the development of high-speed and high-torque spindles, greatly improving machining efficiency and precision.

Applications of Spindles in Various Industries

Spindles are utilized across various industries, including automotive, aerospace, and manufacturing, showcasing their versatility and indispensability in modern machining.

Advantages of Using High-Quality Spindles

Investing in high-quality spindles can offer numerous benefits, including enhanced precision, reduced downtime, and increased overall productivity.

Frequently Asked Questions

What materials are spindles made of?

Spindles are typically made from high-strength materials such as steel or alloy to withstand high operational demands.

How does spindle speed affect machining?

Spindle speed directly influences the cutting efficiency and surface finish quality. Proper speed settings are crucial for optimal results.

What is the lifespan of a milling machine spindle?

The lifespan of a spindle depends on usage and maintenance practices, but it generally ranges from several years to over a decade with proper care.

For a deeper understanding and further details on milling machines, you can visit this comprehensive guide.

Conclusion

Understanding what is spindle in milling machine is fundamental for anyone involved in the machining industry. From improving precision to enhancing operational efficiency, the spindle plays a crucial role in modern milling machines.

For more insights on related technologies, you can check out the precision monitoring used in genetic analysis, or explore high-speed inspection systems in semiconductor manufacturing.