In the world of machining, finding the best small milling machine to upgrade can feel like searching for a needle in a haystack. With advancements in technology, industry professionals now have a plethora of options to choose from. This article explores various small milling machines, their benefits, and how to select the right one for your needs.

Understanding Milling Machines

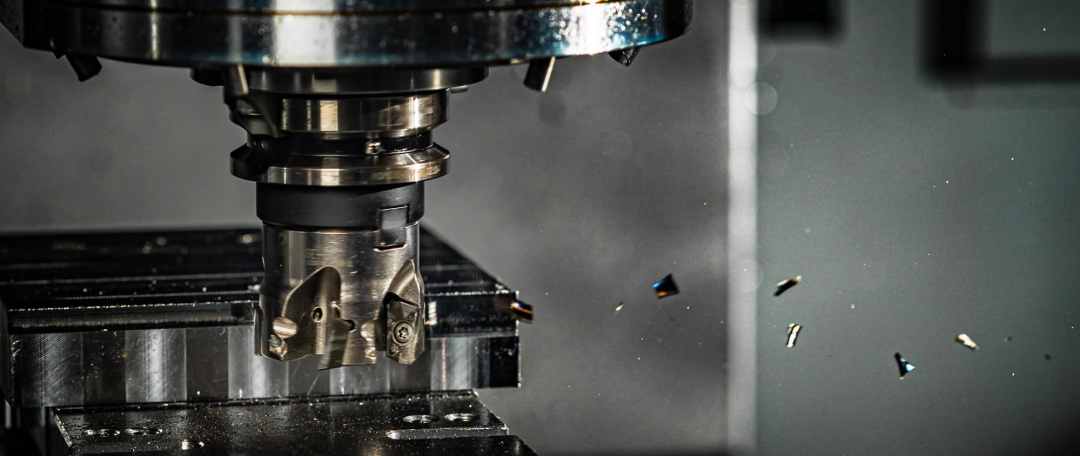

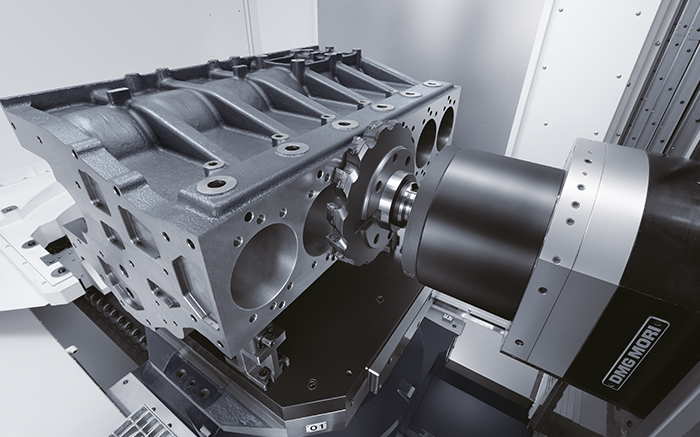

Before diving into the best small milling machines, it’s crucial to understand what a milling machine is. Essentially, a milling machine removes material from a workpiece using rotary cutters. This machinery is indispensable in manufacturing and prototyping industries. For a deeper dive into milling machines, visit this comprehensive guide.

Why Upgrade to a Small Milling Machine?

Upgrading to a small milling machine brings several advantages. They save space, reduce operational costs, and provide precision. Small milling machines are versatile, enabling users to execute complex tasks with ease.

Key Features to Consider

Motor Power

Motor power is a critical factor. Opt for machines with a motor powerful enough for your tasks. A motor that is too weak can hinder productivity.

Spindle Speed

Spindle speed dictates the quality of your milling. Higher speeds allow for finer, more precise cuts.

Build Quality

Solid construction, especially in the frame and spindle, ensures stability and longevity.

Top Small Milling Machines for 2024

Proxxon 37110 Micro Mill

The Proxxon 37110 is known for its durability and precision. It’s suitable for both beginners and professionals.

JET JMD-18 350018

The JET JMD-18 offers a perfect blend of performance and affordability. Its large work table and powerful motor make it ideal for various milling tasks.

Grizzly G8689 Mini Milling Machine

The Grizzly G8689 is a robust machine, perfect for small projects. Its compact design makes it a favorite among hobbyists.

Tips for Maintaining Your Milling Machine

Proper maintenance can extend the life of your milling machine. Regularly check and replace worn-out parts, and ensure the machine is well-lubricated.

Frequently Asked Questions

What is the difference between a milling machine and a lathe?

A lathe shapes material by rotating it against a cutting tool, while a milling machine uses rotary cutters to remove material from a stationary workpiece.

How often should I maintain my milling machine?

Regular maintenance should be performed monthly, with a more thorough inspection and service yearly.

Can I use a small milling machine for large projects?

While small milling machines are ideal for minor tasks, they can be used for larger projects with proper adjustments and patience.

For further insight on milling processes, visit this external resource. Additionally, check out how event detection and paint inspection leverage similar principles.