For many professionals in the manufacturing industry, choosing the right machine is crucial for achieving optimal results. Two common machines often discussed are the drill press and the milling machine. Anyone working in this field would benefit from understanding what is the difference between a drill press and a milling machine.

While these machines might look similar at first glance, their functions and capabilities are quite different.

Overview of a Drill Press

A drill press is a fundamental tool in many workshops. It is primarily used for drilling precision holes in a variety of materials. The main components include the base, column, table, spindle, and drill head.

Main Features of a Drill Press

- Spindle Speed: Adjustable for various materials.

- Precision: Accurate drilling on a fixed path.

- Ease of Use: Suitable for straightforward drilling tasks.

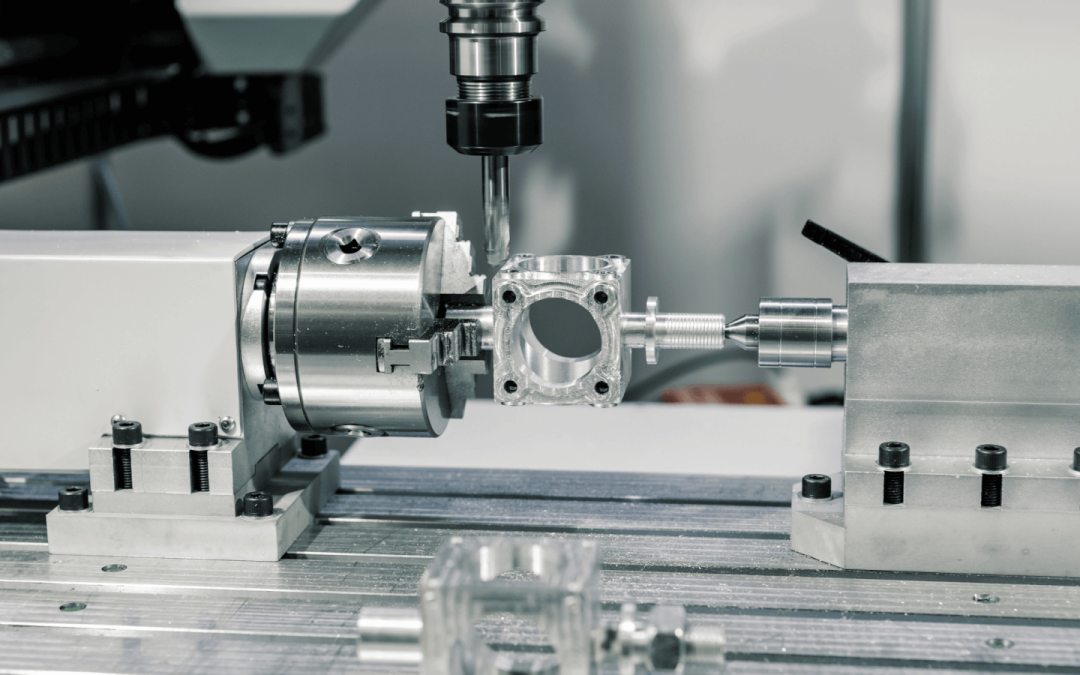

Overview of a Milling Machine

A milling machine is more versatile and can perform more complex tasks than a drill press. It can handle different operations like cutting, drilling, and shaping materials.

Main Features of a Milling Machine

- Versatility: Can perform multiple operations.

- Precision: High accuracy in cutting and shaping.

- Axis Movement: Multiple axes allow for complex designs.

Key Differences Between Drill Press and Milling Machine

When discussing what is the difference between a drill press and a milling machine, several key factors stand out.

Functionality

While a drill press is mainly used for drilling straight holes, a milling machine can cut, shape, and drill, making it more versatile for complex tasks.

Movement Axis

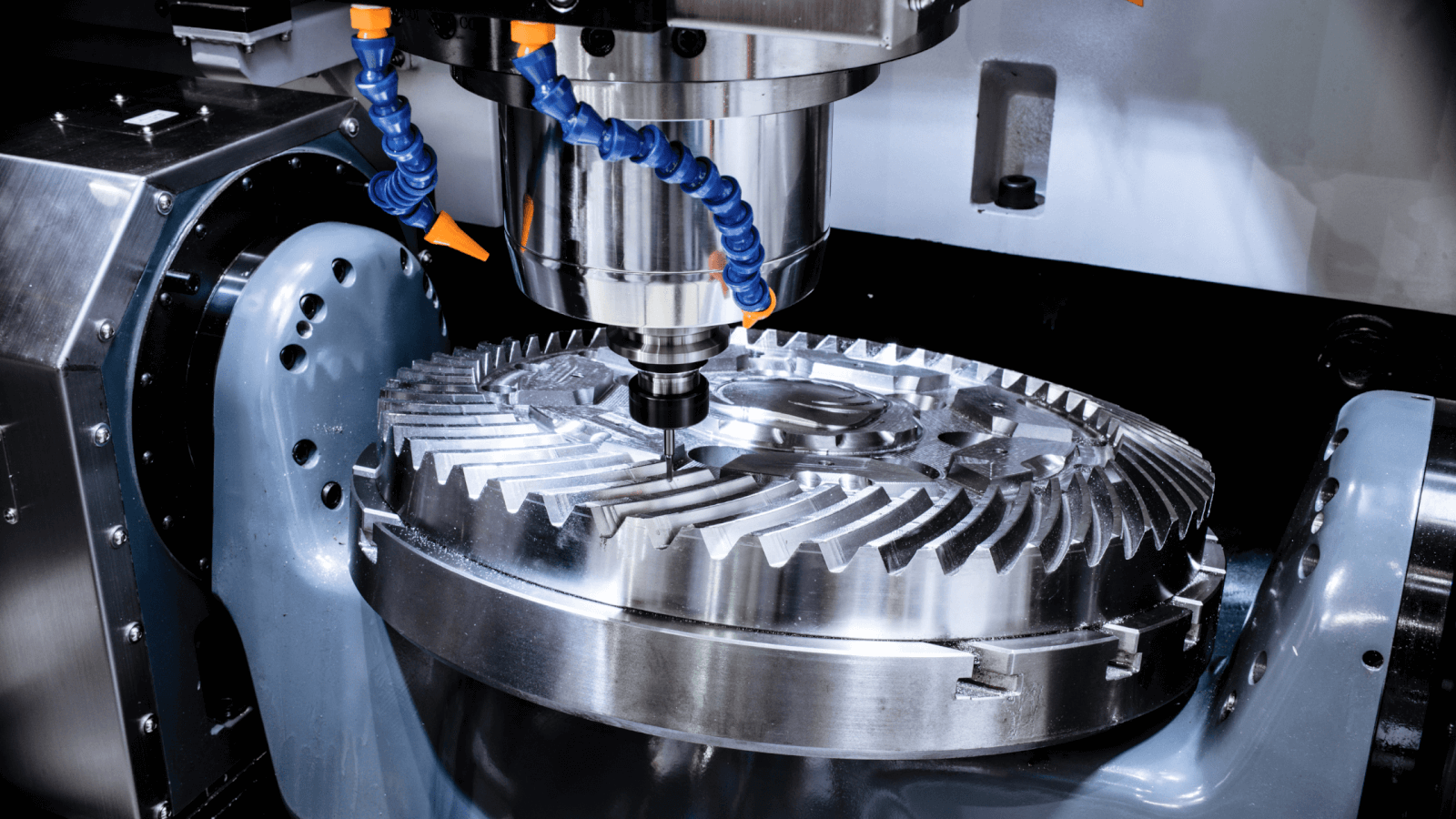

A drill press generally moves along the vertical axis, whereas a milling machine can move along multiple axes (X, Y, and Z), allowing for more intricate work.

Precision

Both machines offer precision, but a milling machine excels in applications requiring fine detailing and intricate patterns.

Applications in Industry

Understanding what is the difference between a drill press and a milling machine is crucial for industry professionals. Each machine has its own set of applications:

Drill Press Uses

- General manufacturing tasks.

- Basic woodworking.

- Metalworking for simple jobs.

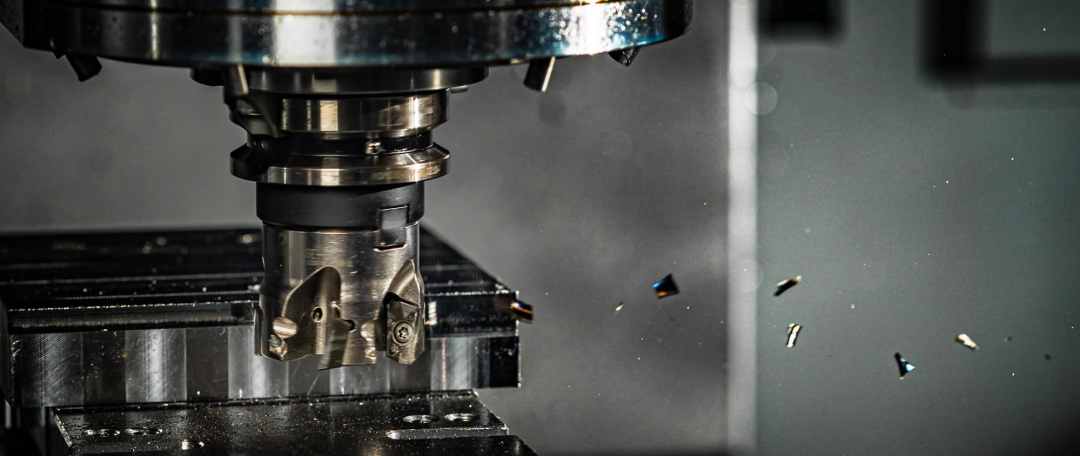

Milling Machine Uses

- Complex metalworking.

- Precise shaping and cutting.

- Prototyping and custom parts manufacturing.

Technology Advancements

Technological innovations have further differentiated these machines in terms of efficiency and capabilities. Drill presses have become more user-friendly, while milling machines have seen advances in automation and computer numerical control (CNC) capabilities.

Choosing the Right Machine

Professionals often face the question of which machine to select. Understanding the primary functions and advantages of each can help in making the right choice.

Considerations for a Drill Press

- Task simplicity.

- Budget constraints.

- Space limitations.

Considerations for a Milling Machine

- Complexity of tasks.

- Requirement for precision.

- Budget for advanced technology.

Maintenance and Operation

Both machines require regular maintenance to ensure longevity and efficiency.

Maintaining a Drill Press

- Regular lubrication.

- Periodic check-ups.

- Proper storage.

Maintaining a Milling Machine

- Consistent cleaning.

- Lubrication of moving parts.

- Software updates for CNC machines.

Safety Measures

Safety should always be a priority when operating either machine.

Drill Press Safety

- Wear protective gear.

- Secure the material firmly.

- Follow manufacturer guidelines.

Milling Machine Safety

- Use appropriate guards.

- Avoid loose clothing near moving parts.

- Ensure proper training before use.

Cost Considerations

Budget can be a significant factor in choosing between a drill press and a milling machine.

Drill Press Costs

- Generally more affordable.

- Lower maintenance costs.

Milling Machine Costs

- Higher initial investment.

- Potentially higher maintenance costs.

Conclusion

Understanding what is the difference between a drill press and a milling machine is essential for making informed decisions. Both machines offer unique benefits tailored to specific tasks. By considering the functionality, precision, and specific needs, professionals can choose the right machine for their operations.

If you’re delving deeper into complex manufacturing processes, exploring detailed insights and manuals can further aid in making the right choice. For more on advanced stroboscopic event detection, visit stroboscopic detection or look into high-speed inspection techniques here.

FAQ

What are the main uses of a drill press?

A drill press is primarily used for drilling precise and uniform holes. It is commonly used in woodworking, metalworking, and various manufacturing processes.

Can a milling machine perform drilling tasks?

Yes, a milling machine can drill holes. In addition to drilling, it can also cut, shape, and perform more complex tasks, making it a versatile machine.

Which machine is more suitable for beginners?

A drill press is generally easier to operate and more suitable for beginners. Milling machines require more expertise due to their complex functionalities.