Industry QA professionals often find themselves grappling with an important question: What is the difference between lathe and milling machine? Both machines are fundamental to manufacturing, yet their functions, capabilities, and operations vary significantly. This article aims to provide in-depth and engaging insights into the core differences between a lathe and a milling machine. With the rising adoption of modern manufacturing technologies, it’s crucial for professionals to grasp the advantages and applications of these essential tools.

The Purpose and Role of Lathe Machines

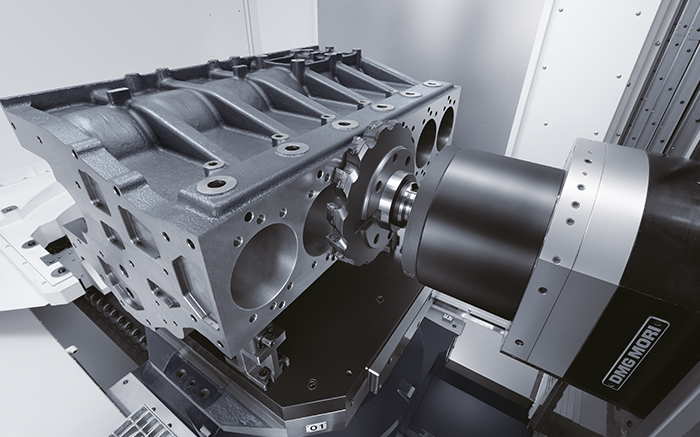

Lathe machines have a long-standing history in the manufacturing world. Traditionally, they are used to create cylindrical parts by rotating the material against a cutting tool. The lathe machine’s primary function is turning, but it can also perform facing, threading, and cutting.

Historical Significance and Evolution

The lathe dates back centuries, making significant strides in human civilization and craftsmanship. Originally, lathes were manually operated, but the advent of modern technology has led to CNC (Computer Numerical Control) automation, enhancing precision and efficiency.

Primary Functions and Applications

Lathe machines are indispensable for producing symmetrical objects such as rings, shafts, and screws. They are widely used in various industries, including automotive, aerospace, and metalworking.

Understanding Milling Machines

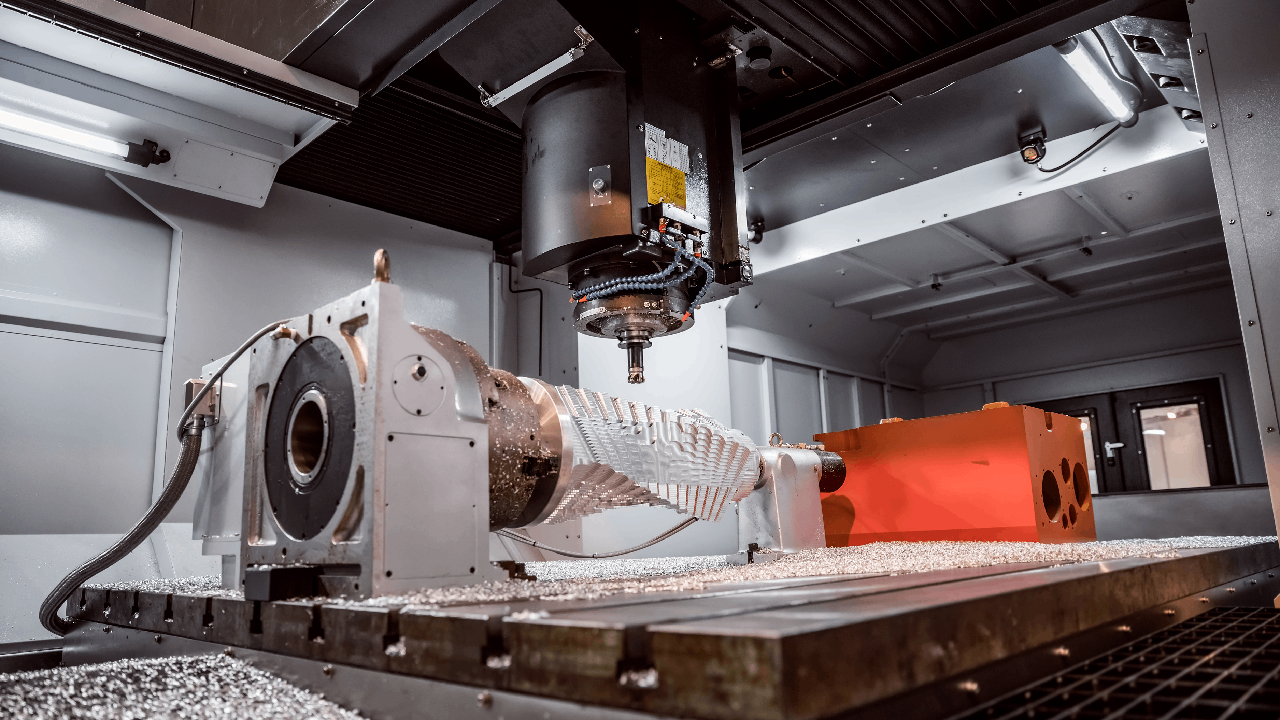

Similar to the lathe, the milling machine holds a vital role, particularly in the creation of complex parts. These machines use rotary cutters to remove material from a workpiece, allowing for multi-axis control and highly detailed work.

The Advent and Utility

Milling machines have evolved dramatically since their inception. Today, you can find advanced milling machines capable of executing tasks with remarkable speed and precision. This is particularly essential in industries demanding intricate and complicated designs, such as aerospace and electronics.

Versatile Functions and Versatility

Unlike the lathe, a milling machine can perform a wide range of tasks, including drilling, cutting slots, and shaping surfaces. Their versatility makes them invaluable in manufacturing prototypes and custom parts.

Key Differences Between Lathe and Milling Machines

Understanding what differentiates a lathe from a milling machine is pivotal to making informed decisions in a manufacturing setup. Here are some fundamental differences:

Operational Mechanism

A lathe machine works on a rotating workpiece, whereas a milling machine uses rotary cutters to remove material from a stationary workpiece. This distinction is crucial for determining the type of parts you can create with each machine.

Design and Structure

Lathes have a simpler design, primarily focusing on rotational symmetry. In contrast, milling machines are more complex, with multiple moving parts and axes to allow for detailed work on various planes.

Material Removal Process

In a lathe, the material removal process is linear and revolves around the workpiece axis. Milling machines, however, can remove material in a multi-directional manner, making it suitable for complex and intricate designs.

Types of Workpieces

Lathes excel in creating cylindrical forms, while milling machines are more versatile, capable of handling irregular shapes and varied materials. This versatility is particularly beneficial in advanced manufacturing processes.

When to Use a Lathe Machine

Choosing between a lathe and a milling machine depends on the specific needs of your project. Here are some scenarios where a lathe would be more appropriate:

- Creating cylindrical objects like rods, spindles, and rings.

- Performing work that requires continuous rotation of the workpiece.

- Projects needing high symmetry and rotational accuracy.

When to Use a Milling Machine

On the other hand, you would opt for a milling machine in the following cases:

- Manufacturing complex parts with intricate details.

- Creating flat surfaces and custom shapes.

- Working with hard materials and requiring high precision.

Cost Implications and Budget Considerations

The cost of these machines varies significantly. Generally, milling machines tend to be more expensive due to their complexity and advanced capabilities. However, the decision should consider the specific requirements and long-term benefits for your operation. For instance, investing in a high-speed milling machine might offer better returns for projects needing intricate work.

Skill Requirements

Operating a Lathe

Lathe machines generally require less specialized training for basic operations. However, achieving precision and expertise does necessitate experience and skill.

Operating a Milling Machine

Given their versatility and complexity, milling machines typically require advanced training and expertise. Operators must be proficient in handling various tools and software for optimal performance.

Maintenance and Upkeep

Lathe Maintenance

Maintaining a lathe machine is relatively straightforward. Regular lubrication, timely replacements of worn parts, and periodic inspections are generally sufficient.

Milling Machine Maintenance

Milling machines demand more rigorous maintenance procedures. This includes regular software updates, tool calibration, and thorough cleaning to prevent debris buildup.

Future Trends in Lathe and Milling Machines

The advent of Industry 4.0 and smart manufacturing technologies is transforming both lathe and milling machines. Innovations such as IoT, AI, and advanced robotics are likely to further enhance efficiency and precision.

Conclusion: Choosing the Right Machine for Your Needs

Deciding between a lathe and a milling machine boils down to understanding your specific requirements and project goals. Both machines offer unique capabilities that can significantly enhance your manufacturing outcomes when used appropriately.

FAQs

1. What are the key differences in operation between a lathe and a milling machine?

Lathe machines rotate the workpiece against a stationary cutting tool, ideal for cylindrical shapes. Milling machines use rotary cutters to remove material from a stationary workpiece, suitable for complex and intricate designs.

2. Which machine is more versatile?

Milling machines are generally more versatile due to their ability to perform a wide range of operations, including drilling, shaping surfaces, and creating intricate details.

3. Which machine is easier to operate?

Lathes are generally easier to operate for basic tasks and require less specialized training. However, achieving high precision with a lathe also demands skill and experience.