For industry QA professionals and anyone interested in precision machining, understanding what is tramming a milling machine is crucial. Tramming refers to the process of adjusting the head of a milling machine so that it is perpendicular to the table or the material being worked on. This alignment is essential for achieving accurate and high-quality milling results, making it a fundamental skill in the machinists toolkit.

The Importance of Tramming

Tramming ensures that all machined surfaces are true and perpendicular to the milling table. Without proper tramming, the machine can produce parts that are out of specification, causing wasted material and time. For professionals, especially those in quality assurance, maintaining machine accuracy is non-negotiable.

Tools Required for Tramming

Before we get into the tramming process, its important to know the tools you’ll need:

- Dial Indicator

- Square Edge

- Adjustable Wrenches

Each of these tools plays a significant role in making sure your milling machine is perfectly trammed.

Step-by-Step Guide to Tramming

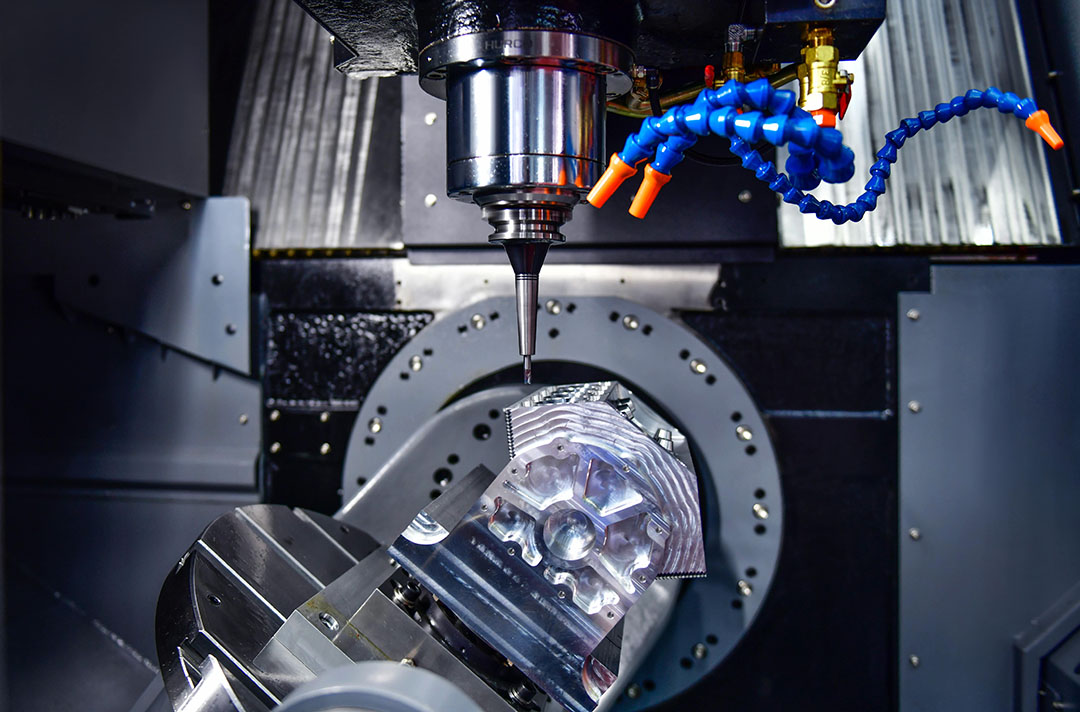

Initial Setup

First, make sure your milling machine is clean and free of debris. Place your dial indicator in the spindle and make sure it’s zeroed out.

Adjusting the Head

Using the adjustable wrenches, make small adjustments to the head based on the readings from your dial indicator. The goal is to get the dial to read zero at multiple points around the table.

Final Checks

Once your initial adjustments are made, take final readings at various points to confirm that the head is perpendicular to the table in all directions. Fine-tune any adjustments as necessary.

Common Mistakes to Avoid

Even with careful attention, mistakes can happen. Here are some common issues to watch out for:

- Not cleaning the table and tools properly can lead to misalignment.

- Over-adjusting the head can cause inaccuracies.

- Ignoring worn-out parts which can affect tramming even if procedures are followed accurately.

Deeper Insights into Tramming

For an even more in-depth understanding of tramming and its importance, professionals often turn to additional resources and advanced machinery capabilities for better precision. Exploring dedicated tools and advanced techniques can significantly reduce the trial-and-error process.

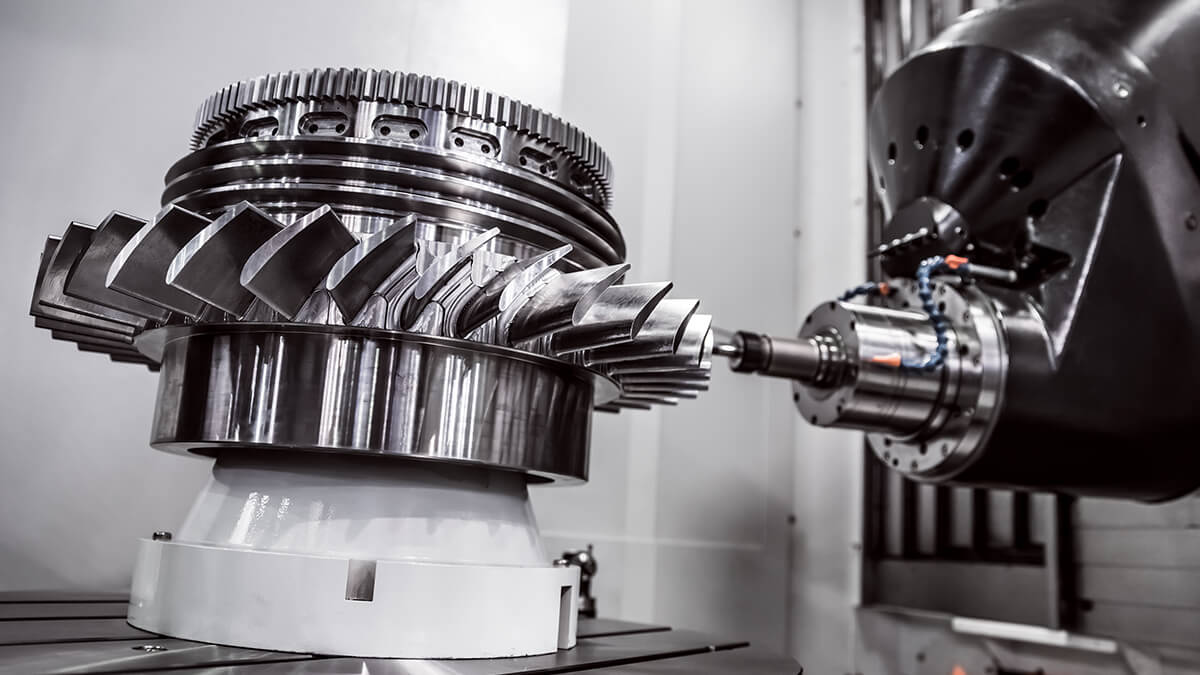

Industry Applications of Tramming

Tramming is vital in industries where precision is key, including automotive, aerospace, and electronics. Knowing how to adjust and maintain milling machines ensures higher quality outputs and longer machine life, making businesses more efficient.

New Technologies in Milling

The continuous advancements in milling technology have brought forth machines that have built-in alignment features and digital readouts, making the tramming process easier and faster. However, a fundamental understanding of manual tramming remains valuable.

Linking Tramming with Quality Assurance

For QA professionals, ensuring that all machined parts meet specifications starts with a well-trammed milling machine. This enhances the reliability of production processes and reduces the need for rework and adjustments later in the production line.

Resources for Further Learning

For those interested in diving deeper, several resources offer comprehensive guides and tutorials on tramming milling machines:

FAQs

What is the significance of tramming?

Tramming ensures that the head of the milling machine is perpendicular to the table, which is critical for accurate machining.

How often should tramming be done?

The frequency of tramming depends on usage; however, it’s good practice to check alignment regularly, especially before critical projects.

Can tramming be automated?

Yes, modern milling machines have built-in features for automatic tramming, but understanding the manual process remains essential.

Conclusion

Understanding what is tramming a milling machine is an essential skill for anyone in the machining industry. This knowledge contributes to achieving high-quality, precise machined parts and enhancing overall efficiency in production. For more details on related processes, check out articles on event detection, paint inspection, and genetic analysis.