A tachometer is an essential instrument used in various industries to measure the rotational speed of a shaft or disk, commonly used in vehicles and machinery. The primary sensor that controls the tachometer is pivotal for its accurate readings.

The Importance of a Sensor in a Tachometer

The sensor plays a critical role in the functionality of a tachometer. Without a precise sensor, the tachometer cannot deliver accurate measurements, which could lead to severe mechanical issues.

What Sensor Controls the Tachometer?

The most common sensor used in a tachometer is a magnetic sensor or a Hall Effect sensor. These sensors detect the magnetic field generated by the rotating object and convert it into an electrical signal.

Magnetic Sensors

Magnetic sensors are widely used due to their reliability and accuracy. They can operate in harsh environments and provide consistent readings.

Hall Effect Sensors

Hall Effect sensors are another popular choice. They work based on the Hall Effect principle, which states that a voltage difference is created across an electrical conductor when a magnetic field is applied perpendicular to the current flow.

How Do These Sensors Work?

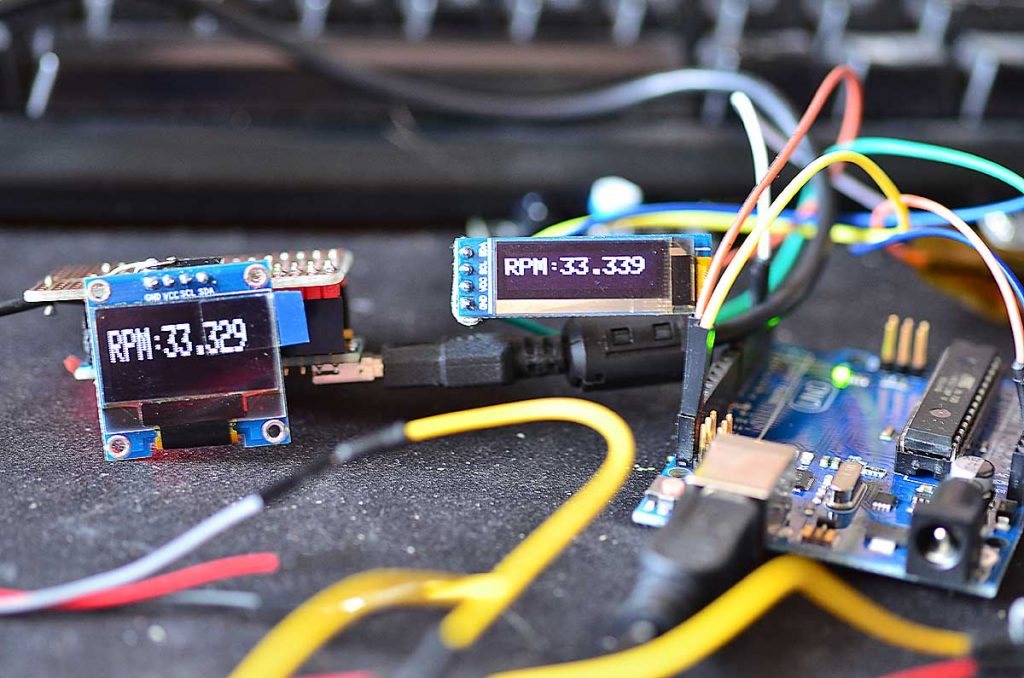

These sensors work by detecting the rotational movement of the object and converting it into an electrical signal. This signal is then processed by the tachometer to display the rotational speed.

Signal Processing

The electrical signal generated by the sensor is often a series of pulses. The tachometer processes these pulses to calculate the rotational speed.

Applications of Tachometers

Tachometers are used in various applications, including:

- Automotive Industry

- Industrial Machinery

- Aerospace Industry

Automotive Industry

In the automotive industry, tachometers are used to measure the engine’s RPM (Revolutions Per Minute) to ensure optimal performance and prevent engine damage.

Industrial Machinery

In industrial settings, tachometers are used to monitor the speed of motors and other rotating equipment, ensuring they operate within safe limits.

Aerospace Industry

In the aerospace industry, tachometers are crucial for measuring the rotational speed of engines and other components, ensuring safety and performance.

Tremendous Technology in Sensor Development

With advancements in technology, sensors used in tachometers have become more sophisticated, offering higher accuracy and reliability. Modern sensors can operate in extreme conditions and provide real-time data.

Advanced Magnetic Sensors

New developments in magnetic sensor technology have resulted in sensors that can detect even the slightest changes in the magnetic field, providing more accurate readings.

Enhancements in Hall Effect Sensors

Similarly, Hall Effect sensors have seen significant improvements. They now offer better sensitivity and can operate at higher temperatures.

Approved Methods for Sensor Calibration

Calibration is essential to ensure the sensor provides accurate readings. Approved methods for calibrating tachometer sensors include:

- Using a Reference Tachometer

- Using a Calibration Device

Using a Reference Tachometer

This method involves comparing the readings of the tachometer with a reference tachometer known for its accuracy.

Using a Calibration Device

A calibration device generates a known rotational speed, which is then used to calibrate the sensor.

Delighted by Sensor Reliability

The reliability of modern sensors used in tachometers is remarkable. They offer consistent performance, even in challenging environments.

The Role of Software in Sensor Performance

Software plays a crucial role in processing the signals from the sensor and displaying accurate rotational speed. Advanced algorithms enhance the performance and reliability of the tachometer.

FAQ

What is the primary function of a tachometer?

A tachometer measures the rotational speed of a shaft or disk, commonly used in vehicles and machinery.

What types of sensors are commonly used in tachometers?

The most common sensors used in tachometers are magnetic sensors and Hall Effect sensors.

Why is sensor calibration important?

Calibration ensures the sensor provides accurate readings, essential for the reliable performance of the tachometer.

For more in-depth information, refer to this external resource.