Tachometers are indispensable in various industries, providing real-time feedback on rotational speeds. The basic question, ‘what unit in a tachometer system sends information to the indicator?’ is pivotal for anyone working with these devices. Understanding this can aid industry QA professionals in ensuring accuracy and efficiency in their operations.

How Tachometer Systems Work

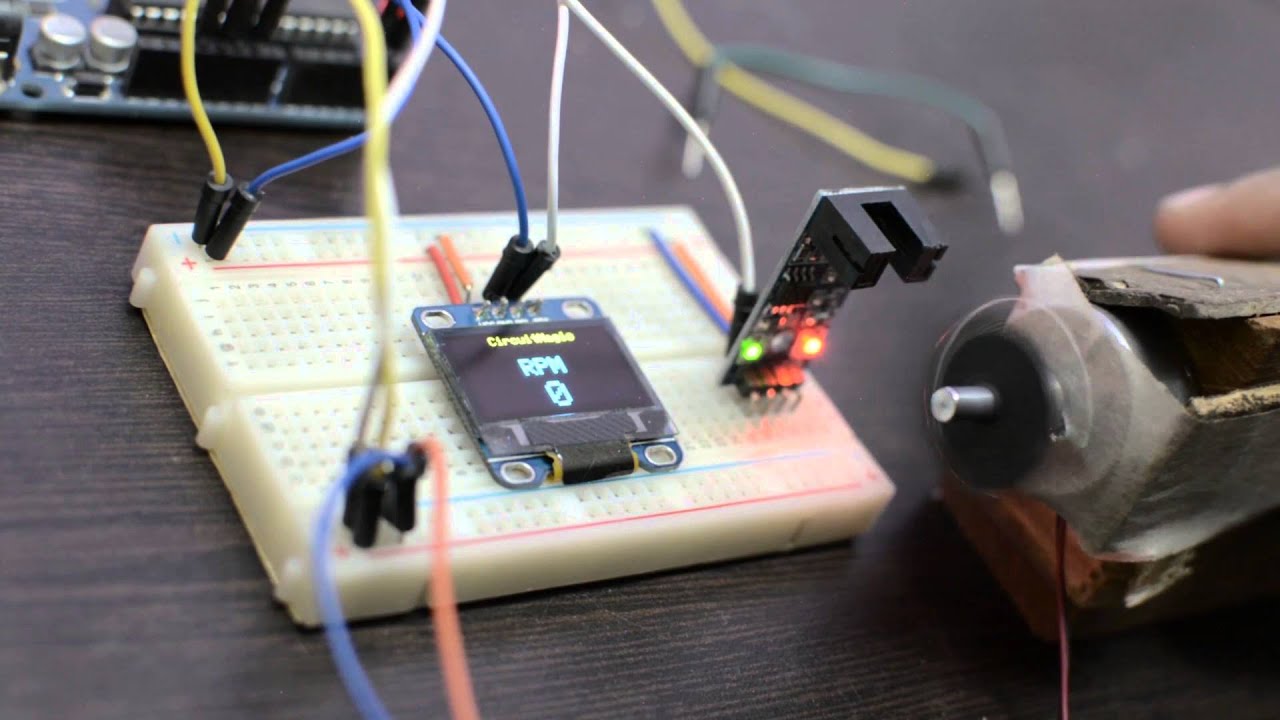

A tachometer system is designed to measure the rotational speed of an object. It typically consists of three main components: the sensing unit, the signal processor, and the display unit. The key player here is the sensing unit, which detects the rotations and sends this information to the indicator via a signal processor.

The Role of the Sensing Unit

The sensing unit is the heart of the tachometer system. It’s responsible for detecting the rotational speed of the machinery and converting this mechanical movement into an electrical signal. This unit is often magnetic or optical in nature, depending on the type of tachometer in use.

Different Types of Tachometers

Tachometers can be broadly classified into two categories: digital and analog tachometers.

Digital Tachometers

Digital tachometers, as the name suggests, convert the rotational data into a digital signal. They are typically more accurate and have higher precision, making them suitable for modern industrial applications.

Analog Tachometers

Analog tachometers use a mechanical or electrical system to provide a continuous output that indicates rotational speed. They are often used in applications where continuous monitoring is required.

How the Sensing Unit Communicates With the Indicator

The sensing unit sends information to the indicator by converting mechanical rotations into electrical signals. These signals are then processed by the signal processor, which can amplify, filter, or convert them into a form suitable for display.

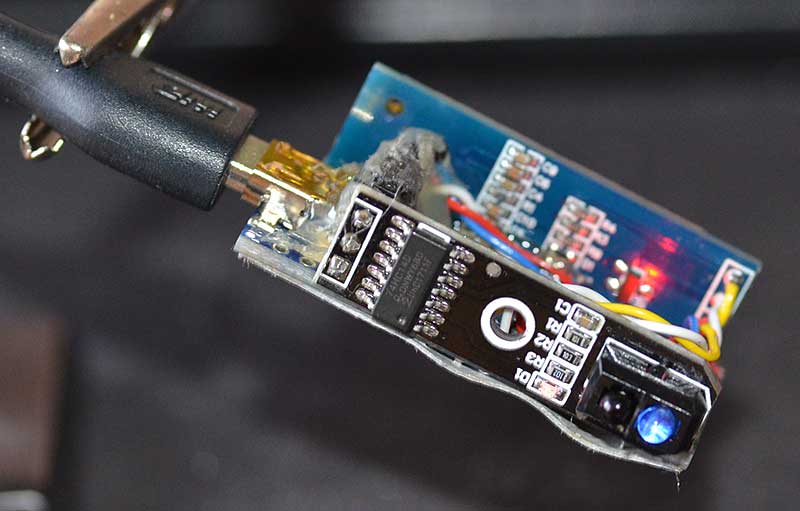

Optical Sensors

Optical sensors use light to detect the speed of rotation. They are highly accurate and are often used in high-precision applications. These sensors work by emitting a light beam onto a rotating disc, which reflects the light back at various intervals. The sensor counts these reflections to determine the rotational speed.

Magnetic Sensors

Magnetic sensors, also known as magnetic pickups, use magnetic fields to detect rotational speed. They are robust and can operate in harsh environments, making them ideal for industrial applications.

Applications of Tachometers in Industry

Semiconductor Manufacturing

The speed and precision of tachometers make them ideal for semiconductor manufacturing. Accurate speed measurement is crucial in processes like high-speed polishing, where rotational speed directly impacts the outcome.

Paint and Coating Inspection

In the paint and coating industry, maintaining consistent rotational speeds ensures uniform application. Tachometers play a vital role in inspection processes, ensuring quality and consistency.

Genetic Analysis & Sequencing

Tachometers are also used in genetic analysis and sequencing to ensure the high-speed rotary components operate within precise parameters.

Engineering and Automotive Applications

Automotive engineering relies heavily on tachometers to monitor engine speeds. This is crucial for performance tuning and diagnostics.

Factors Influencing Tachometer Choice

Accuracy Requirements

The level of accuracy needed in your application will significantly influence your choice. Digital tachometers are known for their precision, making them suitable for applications requiring high accuracy.

Environmental Conditions

The operating environment is another crucial factor. Magnetic sensors are preferred in harsh conditions due to their durability, while optical sensors are used in cleaner environments for better accuracy.

Cost Considerations

Budget constraints also play a role. While digital tachometers are more expensive, they offer higher accuracy and can be cost-effective in the long run due to their reliability.

Maintaining Your Tachometer System

Regular Calibration

Ensuring that your tachometer is regularly calibrated is essential for maintaining accuracy. Calibration should be done according to the manufacturer’s guidelines and industry standards.

Environmental Factors

Regularly check that the sensors and other components are protected from environmental factors such as dust, moisture, and temperature extremes.

Troubleshooting Common Issues

Understanding common issues that may arise can help in troubleshooting. Issues like signal loss, inaccurate readings, or sensor damage should be addressed promptly.

Future Trends in Tachometer Technology

Integration with IoT

The integration of tachometer systems with the Internet of Things (IoT) is a trend gaining momentum. This allows for real-time data collection and remote monitoring, enhancing operational efficiency.

Advancements in Sensor Technology

Continuous advancements in sensor technology are making tachometer systems more accurate and reliable. Innovations like wireless sensors and AI integration are on the rise.

Sustainability Considerations

The move towards sustainable technology is also impacting the development of tachometer systems. Focus is shifting towards energy-efficient designs and environmentally friendly materials.

Conclusion

Understanding what unit in a tachometer system sends information to the indicator is crucial for ensuring the accuracy and efficiency of these systems. As technology advances, tachometers will continue to play a vital role in various industries, providing the necessary data to drive performance and innovation.

FAQ

What is the primary function of a tachometer?

The primary function of a tachometer is to measure the rotational speed of an object, typically measured in revolutions per minute (RPM).

Are digital tachometers more accurate than analog ones?

Yes, digital tachometers are generally more accurate due to their ability to convert rotational data into precise digital signals.

How does a magnetic sensor work in a tachometer?

A magnetic sensor detects rotational speed by using magnetic fields. It is robust and suitable for harsh environments, making it ideal for industrial applications.

Additional Reading

For more detailed information, you can check the Britannica article on Tachometers.