The manufacturing of jet lathes has a tremendous influence on various industries. Knowing where jet lathes are made is crucial for industry QA professionals and others in the manufacturing industry. In this article, we will delve deep into the production process and origins of these vital tools and why understanding their origins is critical.

Introduction to Jet Lathes

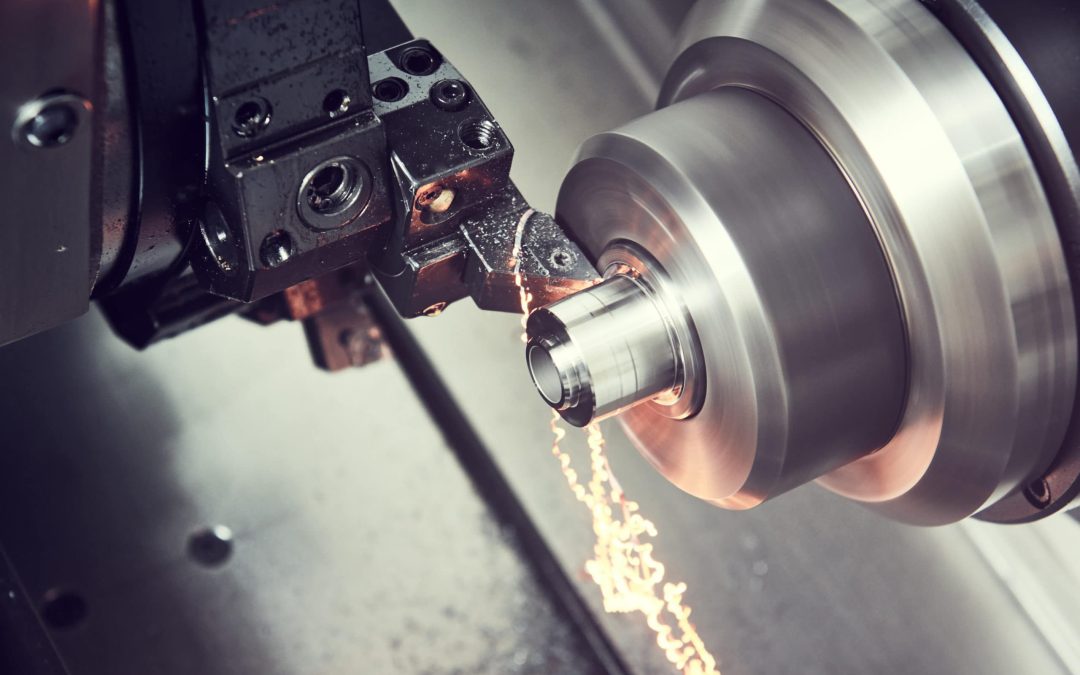

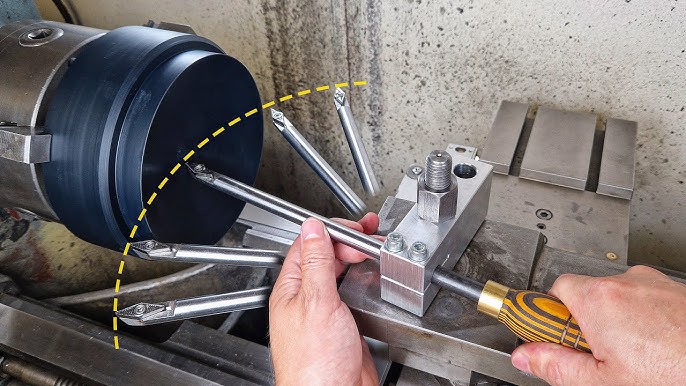

Jet lathes are known for their precision and durability, used extensively in metalworking and woodworking. Their build quality and versatility make them a favorite among professionals.

History of Jet Lathes

Since their invention, lathes have evolved tremendously. Initially created for simpler tasks, today’s jet lathes are marvels of technological advancement.

Primary Locations of Jet Lathes Manufacturing

Jet lathes are manufactured in several countries. The primary locations include:

- United States

- Germany

- China

- Japan

Why These Locations?

The choice of these locations is influenced by access to materials, skilled labor, and technology.

United States

The US boasts a robust manufacturing sector, making it a leading producer of jet lathes.

Germany

Known for its precision engineering, Germany produces high-quality jet lathes.

China

China’s mass production capabilities make it a key player in the jet lathe market.

Japan

Japan’s focus on innovation has led to some of the most advanced jet lathes.

Quality Control in Jet Lathe Manufacturing

Stringent quality control measures ensure that each jet lathe meets high standards.

The Role of Technology in Manufacturing Jet Lathes

Advanced technologies have revolutionized jet lathe production, ensuring precision and efficiency.

Materials Used in Jet Lathes

Materials such as high-grade steel and cast iron are critical in jet lathe production.

Impact on the Industry

The production of jet lathes significantly impacts various industries, including automotive, aerospace, and manufacturing.

Environmental Considerations

Modern manufacturing processes aim to minimize environmental impact, incorporating sustainable practices.

Future Trends in Jet Lathe Manufacturing

Trends include increased automation, AI integration, and sustainability in jet lathe production.

FAQs

What are the primary materials used in jet lathes?

High-grade steel and cast iron are the primary materials used.

Why is it important to know where jet lathes are made?

Knowing the origin helps assess the quality and reliability of the product.

What is the future of jet lathe manufacturing?

Future trends include automation and AI integration, focusing on precision and efficiency.

For more detailed information on how lathes work, you can refer to this external link.

To explore more insights on related manufacturing technologies, visit our articles on Gene Analysis, Paint Inspection, and Event Detection.