Understanding the alternator and its terminals can sometimes be perplexing, especially for professionals who deal with automotive or machinery diagnostics. One common query is: which alternator terminal can be used to operate a tachometer or hour meter? The answer to this question is crucial as it directly impacts the efficiency and accuracy of your diagnostic tools.

In this article, we aim to provide comprehensive insights into the role of alternator terminals and how they can be utilized for operating tachometers and hour meters. Whether you are a seasoned professional or a newbie in the industry, this guide will offer you valuable information to make informed decisions.

The Role of an Alternator

The alternator is a critical component in any vehicle’s electrical system. It converts mechanical energy into electrical energy to charge the battery and power the electrical systems when the engine is running. Understanding the various components of the alternator is the first step towards knowing which alternator terminal can be used.

Functionality of Alternator Terminals

Alternators have multiple terminals, each serving a unique purpose. The primary terminals include:

- Battery Terminal (B+): Provides continuous battery charge.

- Field Terminal (F): Controls the charging rate.

- Ground Terminal (GND): Connects to the vehicle’s chassis.

- Stator Terminal (S): Works with the rectifier to produce AC voltage.

Among these, the Stator Terminal (S) is most commonly used for operating a tachometer or hour meter.

How a Tachometer Works with Alternator

A tachometer measures the rotational speed of the engine. It is essential for diagnosing engine performance and ensuring that the vehicle operates within the recommended RPM range. When it comes to connecting a tachometer to the alternator, the stator terminal is often used.

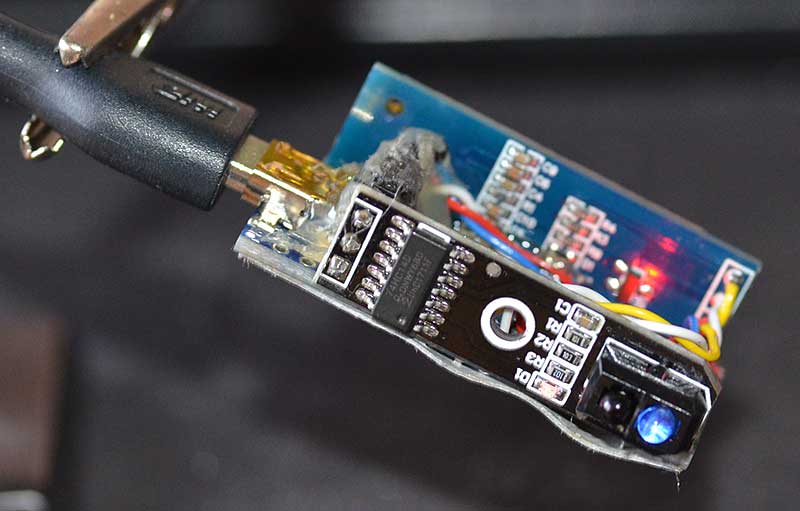

Connecting the Tachometer

To connect a tachometer to an alternator, follow these steps:

- Identify the stator terminal on the alternator.

- Run a wire from the stator terminal to the tachometer signal input.

- Ensure the connections are secure and insulated.

- Calibrate the tachometer according to the manufacturer’s guidelines.

For a detailed guide on installing and calibrating tachometers, refer to this external guide.

Using Hour Meters with Alternators

An hour meter tracks the operating hours of an engine, which is particularly useful for maintenance schedules. The connection process is similar to that of a tachometer, using the stator terminal to signal the hour meter.

Connecting the Hour Meter

Heres how you connect an hour meter to the alternator:

- Locate the stator terminal on the alternator.

- Connect a wire from the stator terminal to the hour meter input.

- Secure all connections and ensure proper insulation.

Importance of Proper Connections

Incorrect wiring can lead to inaccurate readings or even damage to the tachometer or hour meter. Therefore, it’s crucial to double-check all connections and make sure they comply with the manufacturer’s instructions. Professionals often refer to guides for accurate installations. For instance, high-speed processing ensures precision in diagnostic tools.

Safety Precautions

Always disconnect the battery before making any electrical connections to avoid short circuits or electrical shocks. Use quality wires and connectors to ensure longevity and reliability.

Common Issues and Troubleshooting

Even with the correct connections, problems might still occur. Some common issues include:

- Inconsistent Readings: Check for loose connections or faulty wiring.

- No Reading: Ensure that the stator terminal is functioning correctly.

- Erratic Behavior: Verify the calibration of the tachometer or hour meter.

Supportive Technologies

Innovations in diagnostic technologies, like advanced detection, can further enhance the reliability of your tachometer and hour meter installations.

Industry Standards and Best Practices

Adhering to industry standards and best practices is critical for ensuring the accuracy and longevity of your tachometer and hour meter. Industry guides are often a valuable resource for best practices and troubleshooting tips.

Trustworthy Resources

For more insights into best practices, consider visiting trusted resources.

FAQ Section

1. Can I use any alternator terminal for a tachometer or hour meter?

No, the most suitable and commonly used terminal is the stator terminal.

2. What precautions should I take during installation?

Always disconnect the battery before making any connections, and ensure all wiring is insulated and secure.

3. What should I do if my tachometer or hour meter is giving inconsistent readings?

Check for loose connections, faulty wiring, and ensure the calibration is correct.

For more advanced diagnostics and tools, you can explore solutions like these advanced options.