Welcome to an in-depth look into why is tachometer important and how it has established its presence in various industries. In this article, we will explore everything you need to know about this critical device, providing valuable insights for both professionals and enthusiasts.

Introduction to Tachometers

Before diving into the reasons why tachometers are important, it is essential to understand what a tachometer is. A tachometer, also known as a revolution-counter, is an instrument used to measure the rotation speed of a shaft or disk. This legendary device finds applications in cars, airplanes, industrial machinery, and numerous other sectors where rotational speed measurements are crucial.

The History and Evolution of Tachometers

Tachometers have been around for a long time. From mechanical to digital, the evolution of the tachometer has been remarkable. Initially, tachometers were purely mechanical devices that relied on the spinning of gears and mechanisms. However, with advancements in digital technology, today’s tachometers are more accurate, reliable, and versatile.

Mechanical Tachometers

In the early days, tachometers were primarily mechanical. These devices used spinning wheels or cables connected to the moving part whose speed was to be measured. They were widely used in automobiles and industrial machines.

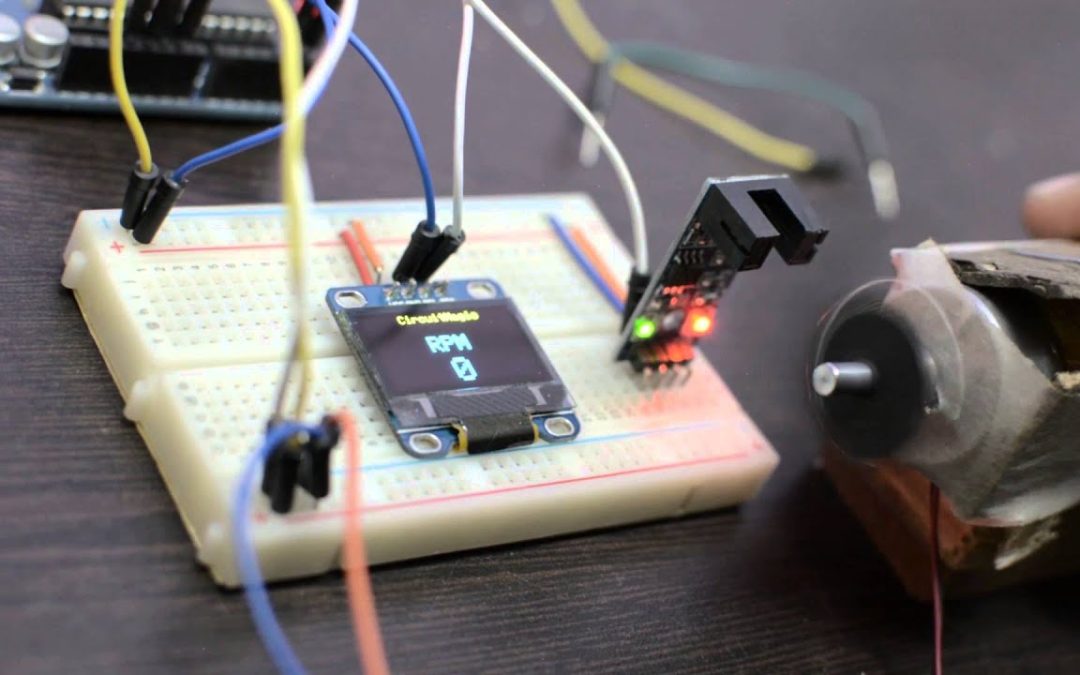

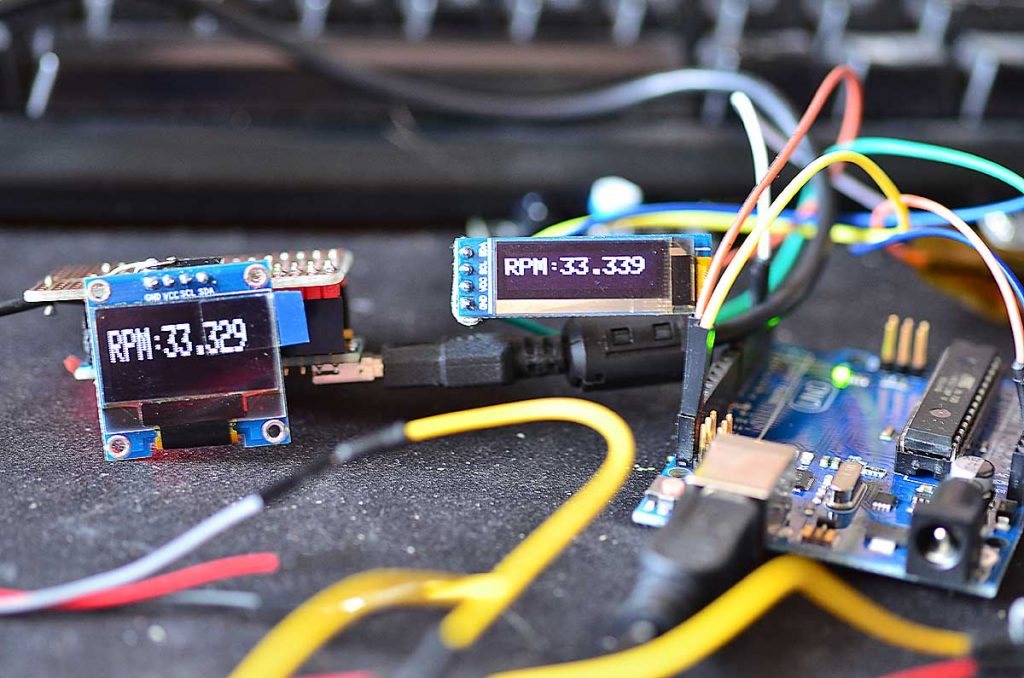

Digital Tachometers

With the advent of digital technology, tachometers have evolved into electronic devices. Digital tachometers offer greater accuracy and can be easily integrated with other systems for data logging and analysis. They are used in high-speed genetic analysis and sequencing monitoring as well as semiconductor wafer polishing inspection.

Why is Tachometer Important in Different Sectors?

The importance of tachometers spans across various industries. Heres a detailed look at sectors where tachometers play a crucial role.

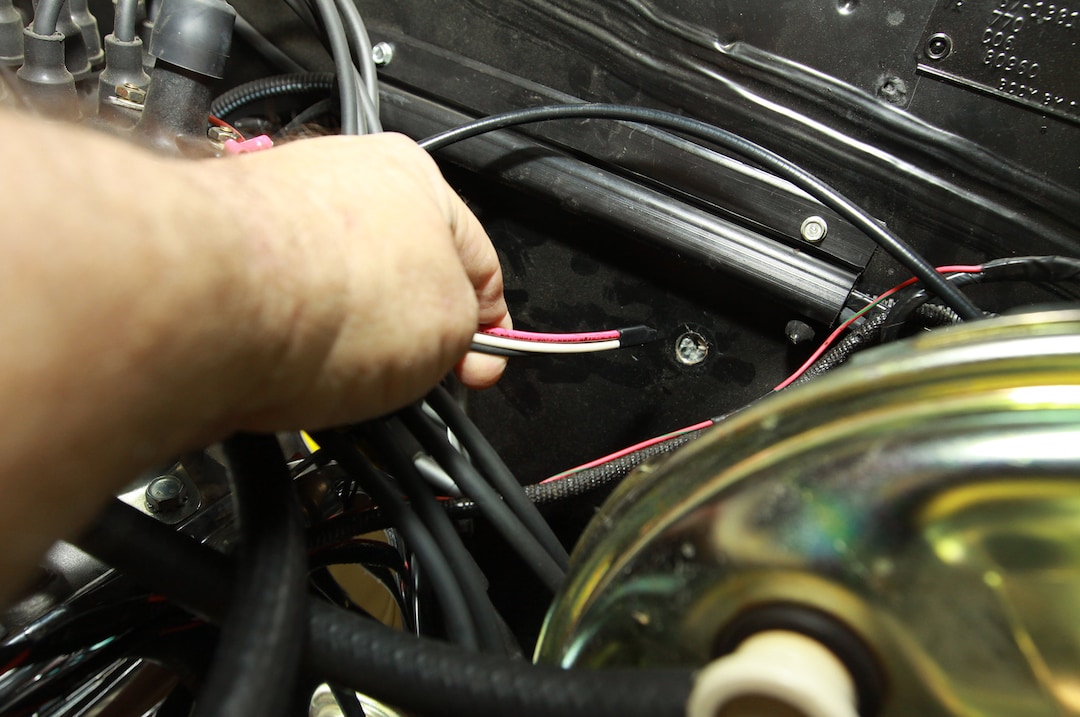

Automotive Industry

In the automotive industry, tachometers are indispensable. They help drivers monitor the engine’s RPM (revolutions per minute) to ensure it operates within a safe range. This prevents engine overloading and potential damage.

Aerospace Industry

In airplanes, tachometers are used to monitor the rotation speed of engines and other mechanical systems. This is crucial for maintaining optimal performance and ensuring safety during flights.

Manufacturing and Industrial Machinery

Tachometers are heavily used in manufacturing plants and industrial machinery. For example, in high-speed paint and coating application inspections, tachometers ensure that machinery operates at the correct speed to achieve the desired results.

Types of Tachometers

There are several types of tachometers available today, each with its unique features and applications.

Contact Tachometers

Contact tachometers come in direct contact with the rotating object to measure its speed. They are commonly used in industries where physical contact with the moving part is feasible.

Non-Contact Tachometers

Non-contact tachometers, as the name suggests, do not require physical contact. They use optical methods such as lasers to measure rotational speed, making them ideal for high-speed and hazardous environments.

Working Principle of a Tachometer

Understanding the working principle of a tachometer can help in appreciating its significance. A tachometer measures the number of rotations per minute (RPM) of an object. This measurement is achieved through mechanical, electrical, or optical means.

Mechanical Measurement

In mechanical tachometers, a rotating shaft is connected to the device. The speed is measured based on the rotation of gears or a spinning disc within the tachometer.

Electrical Measurement

Electrical tachometers use electromagnetic induction to measure RPM. These devices generate an electrical signal proportional to the rotational speed, which is then processed and displayed.

The Benefits of Using Tachometers

The use of tachometers offers several benefits across various industries, enhancing both performance and safety.

Improved Performance

By closely monitoring the rotational speed, tachometers help in optimizing the performance of machines. For instance, in high-speed semiconductor manufacturing inspections, tachometers ensure that the process maintains the correct speed for optimal results.

Enhanced Safety

Safety is paramount in any industry, and tachometers play a vital role in ensuring it. By preventing machinery from operating outside safe RPM limits, tachometers help avoid malfunctions and accidents.

Choosing the Right Tachometer

Selecting the appropriate tachometer for your needs requires understanding various factors. Heres what you should consider.

Application

Identify the specific application for which the tachometer is needed. For example, high-speed semiconductor manufacturing inspection requires highly accurate digital tachometers.

Type

Determine whether a contact or non-contact tachometer is suitable for your application. As mentioned earlier, non-contact tachometers are ideal for high-speed and hazardous environments.

Challenges in Using Tachometers

While tachometers are highly beneficial, they come with certain challenges that need to be addressed for optimal use.

Calibration and Maintenance

Regular calibration is essential to maintain the accuracy of a tachometer. Additionally, proper maintenance is needed to ensure longevity and consistent performance.

Environmental Factors

Tachometers must be protected from adverse environmental conditions such as dust, moisture, and extreme temperatures to ensure reliable performance.

Technological Advancements in Tachometers

Technology continues to evolve, and so do tachometers. Heres a look at some advancements that are shaping their future.

Integration with IoT

Modern tachometers are increasingly being integrated with the Internet of Things (IoT). This allows for real-time data monitoring, analysis, and remote control, enhancing their efficiency and utility.

Smart Tachometers

Smart tachometers equipped with advanced sensors and connectivity options are now available. These devices offer superior accuracy and can be easily integrated with other systems for comprehensive monitoring and analysis.

Conclusion

Tachometers are undeniably crucial in various industries, from automotive and aerospace to manufacturing and beyond. By understanding why tachometers are important, you can appreciate their role in enhancing performance, safety, and efficiency in different applications.

Relevant Links:

For more detailed information, you can refer to the Megadepot guide on tachometers.

FAQs

What are the primary uses of tachometers in the automotive industry?

Tachometers in the automotive industry are used to monitor the engine’s RPM to ensure it operates within a safe range, preventing engine overloading and potential damage.

How do non-contact tachometers measure rotation speed?

Non-contact tachometers use optical methods like lasers to measure rotational speed, making them ideal for high-speed and hazardous environments.

What factors should I consider when selecting a tachometer?

You should consider the specific application, the type of tachometer required (contact or non-contact), and the environmental conditions in which it will be used.