For industry QA professionals and enthusiasts alike, understanding how to wire a 2 wire tachometer is crucial for ensuring precise engine monitoring. This guide will take you through the step-by-step process while providing insights into the technology used, common challenges, and troubleshooting tips. Whether you’re a seasoned pro or a newbie, you’ll find this guide both informative and easy to follow.

What is a 2 Wire Tachometer?

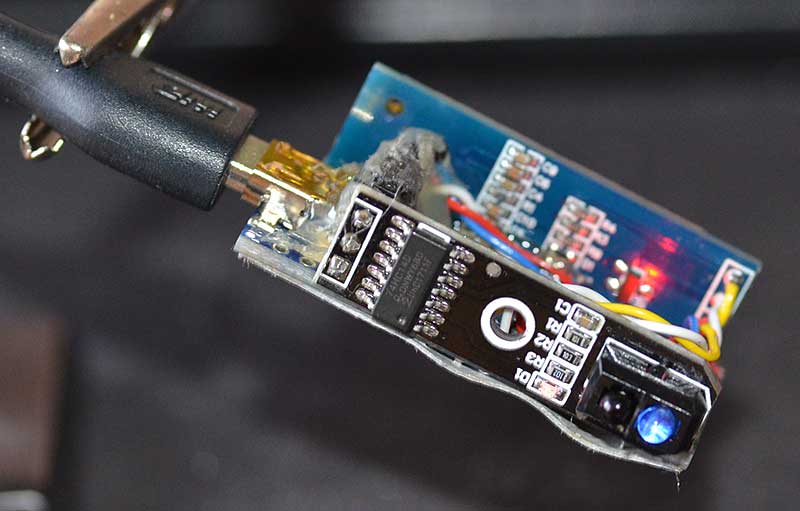

A tachometer is an instrument that measures the rotation speed of an engine or other rotating machinery. Specifically, a 2 wire tachometer is often used in automotive and industrial applications due to its simplicity and reliability. The basic wiring involves connecting two wires: one to the ignition system and the other to the ground.

The Importance of a Tachometer

A tachometer helps in monitoring the engine speed, which is critical for maintaining performance and efficiency. By knowing the engine’s RPM (revolutions per minute), you can make informed decisions about the operating conditions and necessary adjustments.

For more details on the importance and functioning of a tachometer, you can visit this external source.

Tools and Materials Needed

Before you begin the wiring process, make sure you have the following tools and materials:

- Tachometer

- Wire strippers

- Screwdrivers

- Multimeter

- Electrical tape

- Connectors

Step-by-Step Guide

Step 1: Identify the Wires

The first step in wiring your tachometer is to identify the wires. Generally, a 2 wire tachometer will have a signal wire and a ground wire.

Step 2: Locate the Ignition Coil

The signal wire needs to be connected to the ignition coil. Locate the coil in your vehicle or machinery; this is usually near the engine.

For a detailed look at semiconductor applications, visit semiconductor manufacturing.

Step 3: Connect the Wires

Strip the ends of the wires and connect the signal wire to the positive terminal of the ignition coil. Attach the ground wire to a suitable ground point on the engine or chassis.

Step 4: Secure the Wires

Use connectors and electrical tape to secure the wires. Make sure that the connections are tight and free from any potential interference.

Step 5: Testing the Tachometer

After wiring, it’s crucial to test the tachometer to ensure it functions correctly. Turn on the engine and observe the tachometer reading. Use a multimeter to double-check the connections if the reading is inaccurate.

To learn more about high-speed genetic analysis, click genetic analysis.

Common Challenges and Troubleshooting

Erratic Readings

Sometimes, the tachometer might give erratic readings. This is often due to loose connections or electromagnetic interference. Ensure all connections are secure and consider using shielded wires if interference is an issue.

No Reading

If the tachometer shows no reading, double-check the wire connections. Ensure that the signal wire is properly connected to the ignition coil and that the ground wire is attached to a suitable ground point.

Inaccurate RPM

An inaccurate RPM reading can be due to incorrect wire connections or a faulty tachometer. Recheck the wiring and consult the tachometer’s manual for specific troubleshooting tips.

Safety Precautions

Avoid Electrical Hazards

Always turn off the engine and remove the key from the ignition before working on the wiring. This will help prevent electrical shocks and other hazards.

Use Proper Tools

Using the right tools for stripping and connecting wires can make the process safer and more efficient. Avoid using makeshift tools that can cause injury or damage to the wires.

Advanced Tips for Professionals

Using Multimeters

A multimeter is an essential tool for professionals. It helps in verifying connections and troubleshooting issues. Use it to measure voltage, resistance, and continuity in the wiring.

Shielded Wires

For applications prone to electromagnetic interference, consider using shielded wires. These wires have an extra layer of insulation that helps reduce interference, ensuring accurate tachometer readings.

For more on coating applications, visit coating application.

Regular Maintenance

Regularly inspect the tachometer wiring for signs of wear or damage. Replace any frayed or damaged wires to maintain optimal performance.

Conclusion

Wiring a 2 wire tachometer might seem daunting, but with the right tools and knowledge, it becomes a manageable task. By understanding the basics and following the steps outlined in this guide, you can ensure your tachometer is accurately monitoring engine speed. This is not just crucial for performance but also for the longevity of your machinery.

If you need further reading on tachometers, consider checking out ScienceDirect’s topic on tachometers.

Frequently Asked Questions (FAQs)

1. How do I know if my tachometer is wired correctly?

After wiring, turn on the engine and observe the tachometer reading. A correct wiring will show RPM changes as you rev the engine. Use a multimeter for additional verification.

2. Can I use any wire for connecting my tachometer?

It is advisable to use the recommended gauge wire as mentioned in the tachometer’s manual. Using inappropriate wires can lead to inaccurate readings and potential hazards.

3. What should I do if my tachometer is not working?

Check all the wire connections and ensure they are secure. Verify the ground and signal wires are correctly positioned. If the problem persists, refer to the troubleshooting section in the tachometer’s manual.